Kurt Manufacturing Introduces Compact Vise

The 8" DX8 CrossOver vise features a redesigned nut with less weight, a new brush seal design and a larger, stronger bearing pack for more durability.

Share

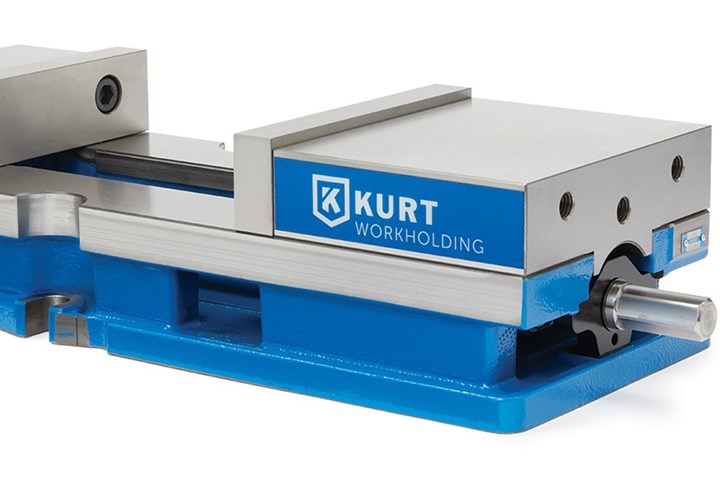

Kurt Manufacturing is bringing its DX-series vise design to an 8" platform with the new DX8 CrossOver vise. Featuring a premium one-piece body design with a cast stationary jaw, the new Kurt DX8 CrossOver combines the features of the Kurt D810 and Kurt 3800V vises into a single vise.

New stationary-jaw Kurt DX8, DX6 and DX4 vises were designed using Finite Element Analysis, which reportedly provides 30% less horizontal push-back deflection than previous DX models. According to Kurt Manufacturing, less vise-body deflection translates to more stability and dimensional precision, as well as precision flatness, parallelism and repeatability. The DX8 CrossOver vise features the same bed height and keyway to the stationary jaw face as the D810. The DX8 also features a redesigned nut with less weight, a new brush seal design and a larger, stronger bearing pack for more durability.

The cast stationary jaw on the DX8 is said to provide additional benefits that improve performance and user experience. The new design eliminates fasteners on the top of the stationary jaw and reduces the chance of body twist during or after assembly. The jaw design also minimizes chip and cutting fluid blowback with no counter bored holes on the top of the jaw to pool fluid and chips. Kurt says the pull-type design now matches the quality and safety of its highest precision 3600V and 3800V vises.

The DX8 CrossOver vise design retains the lifting handle on the back side of the stationary jaw for easy vise positioning and features Kurt’s AngLock spherical segment to create all-directional alignment and reduce jaw lift and improve performance. All DX CrossOver vises use sine keys for easy, accurate mounting and feature a lifetime warranty.

Related Content

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

.jpg;maxWidth=300;quality=90)