Combining Workholding Vises And Fixtures Maximizes Machine Output

This company is a manufacturer of automotive tools and equipment ranging from heavy-duty diesel engine service tools to wheel dollies and bearing cup removers. Many of the components for these products require milling, drilling and tapping on machining centers.

Share

SPX Service Solutions (Owatonna, Minnesota), a unit of SPX Corporation, is a manufacturer of automotive tools and equipment ranging from heavy-duty diesel engine service tools to wheel dollies and bearing cup removers. Many of the components for these products require milling, drilling and tapping on machining centers. One of these machines—a Deckel Maho DMC 80H machining center—uses a workholding system from Kurt Manufacturing (Minneapolis, Minnesota) that accommodates many different size parts for relatively small production runs.

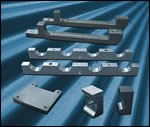

The workholding system combines a full size range of CarvLock cluster towers with DoubleLock vises, equipped with changeable and/or carvable jaws to handle small and large parts. There are four towers, along with five dedicated fixtures mounted on the machining center's automated conveyor pallet. Based on order need, part blanks are loaded into these workholding devices and shuttled into the machining center, which operates 24 hours a day, 5 days a week.

"Our workholding setups allow us to maximize the output potential of our palletized Deckel Maho machining system," reports Daniel Sayner, facilities and manufacturing engineering manager of tools and equipment for SPX. "We have more than 2,000 different part configurations programmed into this machining center. Materials such as tool steel, 4140 steel, aluminum, and castings and investment castings can be machined."

Quantities machined range from one to several dozen, so it's critical that the machine is running efficiently 4 hours a day all week long, with minimal system downtime, Mr. Sayner says. Tolerances are tight, with a target true position of ± 0.005 inch on most machined surfaces.

The horizontal machining center has the capacity to machine a range of materials at high speeds. It has a spindle speed of up to 6,000 rpm with a 900-mm X axis, 710-mm Y axis and 710-mm Z-axis travel. Feed range is up to 40,000 mm/min. The tool magazine holds 180 holders of either SK 50 or HSK A100 mountings. The main drive is powered by a 37-kW, 1005 duty cycle motor with Siemens 840D power line control.

The four cluster tower setups include 4-, 6- and 8-inch capacity Double Lock vises and 8-inch capacity CarvLock vises. "The changeable jaw plate systems give us all of the clamping options we need for our parts," Mr. Sayner says. "The towers and vise combinations are really rigid. We don't have to worry about vibration or chatter because the ductile iron vise bodies damp any tendency to vibrate when aggressive operations are called for. They're as durable as our dedicated fixtures." One jaw set snaps out and another snaps in with little effort in about 60 seconds.

All of the vise systems employ the manufacturer's Anglock design feature that minimizes jaw lift so clamped parts stay properly positioned for precision machining. Each vise has a hard steel screw that clamps by hand with a force up to 5,556 pounds for precise, repeatable clamping.

Related Content

-

Emuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

-

Tungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

.jpg;maxWidth=300;quality=90)