Vertical machining centers with simultaneous five-axis machining capability have become popular in recent years. These machine tools are increasingly affordable and easy to program. Most importantly, they are well suited for the complex geometry that characterizes workpieces often encountered in aerospace, medical, oilfield and die/mold work.

For these applications, five-axis capability enables the cutting tool to reach the workpiece from many sides and many angles. However, the spindle head and projecting cutting tool may need some extra “elbow room” to execute complex five-axis programming commands. Workholding devices and the top of the table can get in the way and limit these five-axis moves. This problem tends to be more pronounced on five-axis machine tools in which the workpiece is swiveled and tilted and less pronounced on machines with an articulated head that tilts and swivels the cutting tool.

As it is, all types of five-axis machines are becoming more popular. In response, a number of suppliers have developed special workholding systems to address the peculiar difficulties with fixturing that can arise.

The main objectives of special five-axis workholding systems are to lift the workpiece away from the worktable surface, position it in the best location/orientation for CNC operations and grip it securely. Other competing considerations also influence the design of these special systems, so they differ in their style and configuration. Users must carefully evaluate how well the various choices meet their needs.

Design characteristics to consider include flexibility, modularity, rigidity, clamping security, affordability, part location repeatability and compatibility with other workholding systems. Also worth considering are how quickly a setup can be put together or changed over, how easily components can be customized and how well components can be adapted for possible use on turning equipment, horizontal machines, grinders or coordinate measuring machines.

A quick look at a few of these systems shows the range of offerings and brings attention to some key concepts for developing an effective five-axis workholding strategy.

Workholding on a Pedestal

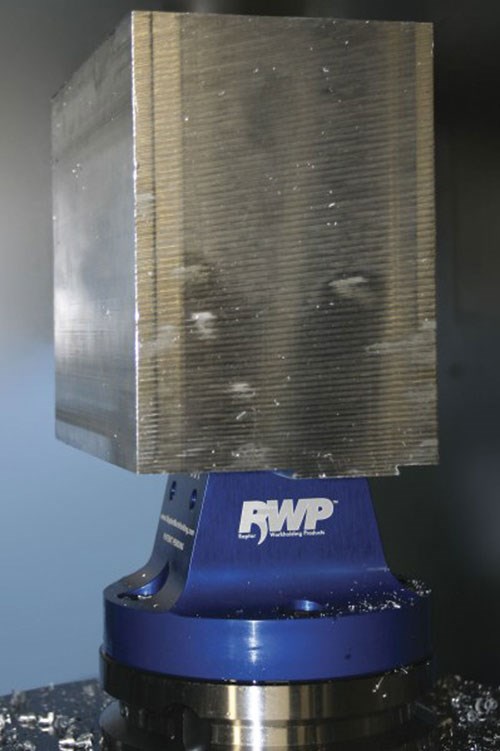

A distinctive feature of several five-axis workholding systems is a basic pedestal-style fixture with a round or square foot and sloping or cone-shaped sides that give it a tapered profile. The height of the profile lifts the workpiece away from the table for clearance, while the taper increases exposure of the machinable workpiece surfaces above.

Another distinctive feature found on some of these pedestal fixtures is dovetail clamping. Opposing clamping surfaces have angled grooves that interface with matching grooves machined into excess material along the underside of the workpiece. (This “dovetail strip” must be removed from the workpiece later.) When the fixture engages the dovetail strip under the workpiece, the resulting joint is extremely strong and secure. The strength of this dovetail joint requires that only a little extra stock be allowed on the workpiece.

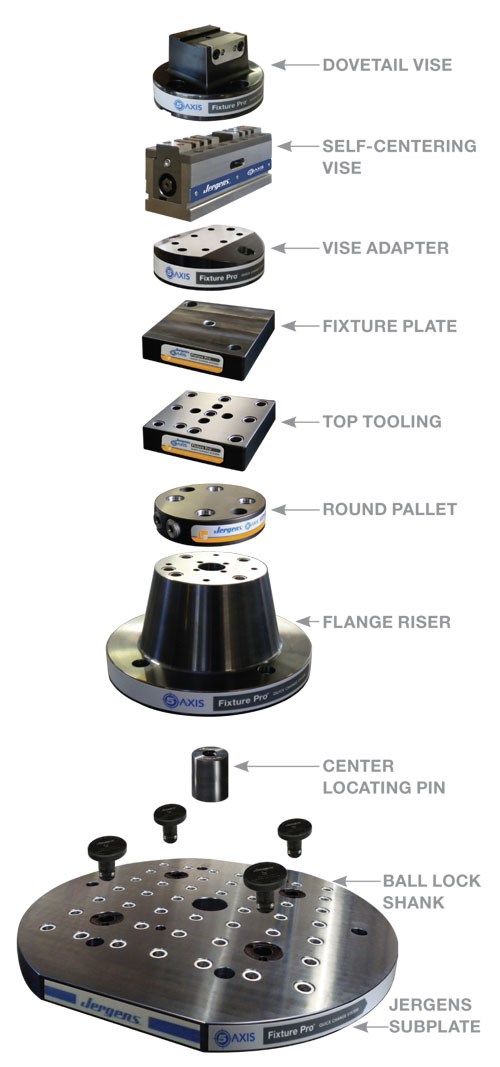

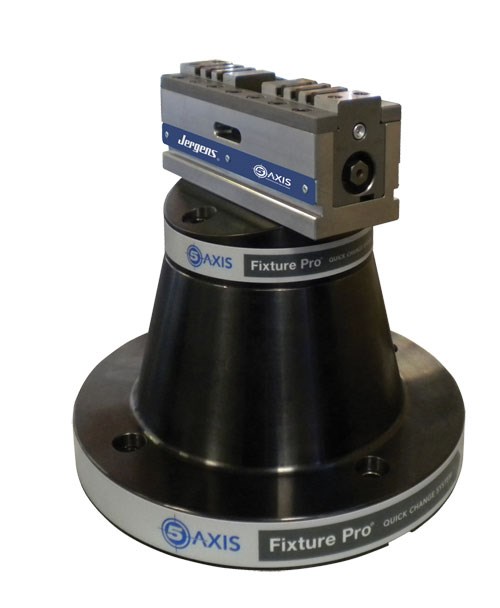

Typically, pedestal fixture systems include a variety of sub/baseplates, risers, and adapters for modularity and flexibility. One of the most extensive systems currently available is the 5-Axis Quick Change Fixturing System from Jergens, Inc. (Cleveland, Ohio). As you might guess, the company promotes the quick-change features and options that the system provides. As a foundation, subplates with a variety of shapes and bolthole patterns enable mounting the system to any machine or rotary table, the company says. The subplate can be configured with the company’s proprietary Ball Lock Mounting System or QLS (Quick Locating System) so that it can be removed from the machine rapidly.

A range of pedestal risers can be mounted to the subplate (also using optional quick-tighten/quick-release bolts) to suit the size of workpiece and provide the desired height from the table top. The topplate for the riser can be either an adapter plate or the company’s Drop & Lock Pallet Changer. The latter enables the clamping element, with appropriate pull studs attached, to be dropped into place and secured with two turns of a hex wrench. The clamping element can be a dovetail vise or a five-axis, self-centering vise with two movable jaws. Both types of vises are available in a range of sizes and styles. All components in the system are made of steel.

The company also emphasizes the importance of its system’s provisions for repeatable locating and positioning of its quick-change fixturing elements. This is accomplished with center locating pins or timing pins between interfacing

components.

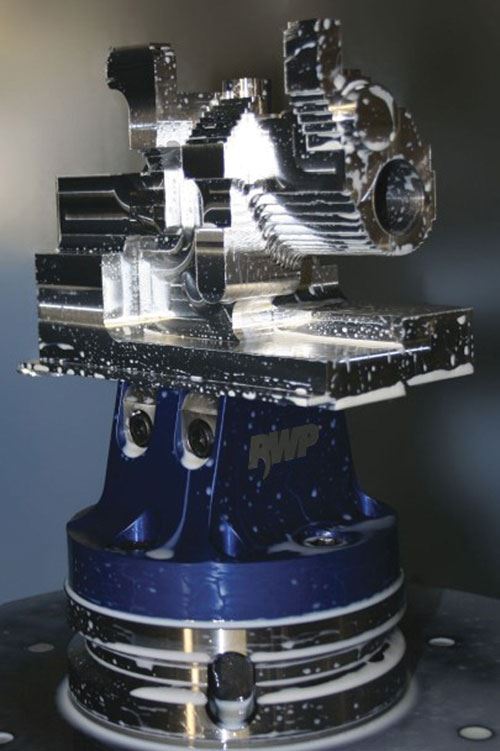

Dedicated Fixturing

Another modular system featuring tapered pedestal-style fixtures with dovetail clamping is offered by Raptor Workholding Products (Burbank, California). Developed collaboratively by two aerospace job shops in Southern California, this system is tailored for shops using palletized production cells built around five-axis machining centers. The basic dovetail fixture, made of anodized aluminum or stainless steel, is available in several sizes. The fixture can be mounted on T-slots or the threaded holes of the standard pallets used on the production cells. Several styles of adapter plates enable the dovetail fixtures to be mounted on the tables or rotary devices of specific models of machine tools from certain builders. Optional risers can provide additional height to the fixture profile for greater clearance.

The company reports that many users leave multiple dovetail fixtures attached to the pallets so that they become dedicated workholding setups for repeat jobs. For this reason, affordability of the fixtures is important.

According to the developers, several features set the basic Raptor fixture apart from other designs. For example, a dovetail interface on one side of the fixture serves as a solid stop against which a workpiece is secured by the spring-loaded, stainless steel dovetail clamps on the opposite side. Another feature, a locating screw adjacent to the solid stop, provides workpiece positioning and prevents a part from being loaded backwards. For workholding purposes, a shallow dovetail strip must be machined on the clamping side of the workpiece. This strip is only 1/8-inch high, so it requires little extra stock. A slot that fits against a locating screw must also be milled. To load a workpiece on the fixture, the operator simply places one side of the dovetail strip against the solid side of the fixture and then tightens the clamps. This presses the material firmly against the solid side. The screws in the clamps are then tightened to secure the workpiece.

The Raptor system now includes a line of modular workholding fixtures that mount on top of existing fixture components. These modular fixtures enable a shop to adapt to different sizes of workpieces without having to remove fixtures from the machine pallet. The company creates additional flexibility by offering components that are compatible with its original dovetail fixtures. For example, a 23-inch-tall tombstone can hold three Raptor fixtures on each of its four sides. A 2X plate bolts two fixtures in a row for clamping long parts. A Dual Raptor fixture holds two parts by combining two sets of dovetail clamping zones, one on each side. The four-sided Raptor Nest has four stations for clamping fixtures.

Vises That Stand Tall

Vises that clamp with movable jaws have been a proven workholding method for milling operations since the earliest days of machining. The design and construction of these devices have evolved along with developments in CNC machining technology. Not surprisingly, vises designed to meet the objectives of five-axis workholding have appeared.

Essentially, these vises feature uprights that hold the workpiece at a suitable distance above the worktable. To keep the uprights from spreading at the top when clamping forces are applied below, the clamping screw is situated close to the clamping surfaces.

An example of such a system is the Maxlock 350 multi-axis Anglock vise from Kurt Manufacturing Inc. (Minneapolis, Minnesota). On one side, the stationary jaw sits atop a 4.625-inch-tall upright that can be mounted to a standard 2-inch by 2-inch grid pattern. An optional riser is available to lift it another 3 inches and will fit on a grid patterns as large as 100 mm. The movable jaw, which has a 0.625-inch stroke, rides on its own base (which can also be used with an optional riser).

The clamping screw is located at the top of the uprights near the clamping surface. It delivers as much as 7,000 pounds of clamping force at 40 foot-pounds of input torque. Available screw lengths of 8, 12, 18 and 24 inches enable the vise to handle any part that fits on the worktable. With this modular design, the minimum jaw opening is 0.15 inch and the maximum is 15.5 inches with the standard screw lengths. The jaws are 3.5 inches wide. The “Anglock” feature of this vise refers to the company’s proprietary design of the internal screw nut that creates downward force on the workpiece proportional to the sideward clamping force exerted by the vise jaws. Part of Kurt’s original innovations in vise design, the Anglock principle counteracts the tendency of a part to lift as the jaws tighten, thus negatively affecting their grip.

Protecting the Investment

For most shops, the move to five-axis machining represents a considerable investment that includes not only the machine tool, but perhaps also cutting tools, programming software and workholding fixtures. It doesn’t make economic sense to skimp on products if they need to be upgraded to get the most out of five-axis machining capability.

When it comes to five-axis workholding, a shop has to decide if acquiring a commercial five-axis workholding system represents a better value than making some or all of the fixtures and components in-house. In this decision, the most important factor is likely to be response time—getting the setup ready as quickly as possible. In that case, the flexibility and modularity of a complete system designed for five axis-machining may be hard to beat.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)