Flexible Workholding Maximizes Machine Output

More and more companies are finding that by juggling work scheduling on their machining centers and adding a vise tower setup on the right machine, they can increase productivity without adding operating hours.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreMore and more companies are finding that by juggling work scheduling on their machining centers and adding a vise tower setup on the right machine, they can increase productivity without adding operating hours.

That was the case at Civacon/Knappco (Parkville, Missouri). The company needed to increase product output to meet increasing demand for its check valves and cargo tank fill covers, so it looked at rescheduling the work on the machines it had along with a different approach for its workholding. Knappco Corp. is a specialized manufacturer of industrial access ports, manholes, hatches, coamings, collars, weld rings, fill covers and check valves used in the handling, transport and storage of petrochemicals, agricultural commodities and building materials such as cement and asphalt. When used in a system, these products are designed to deliver safe, fast loading and unloading while safeguarding against costly spills, tank overfills and emissions.

Many of Knappco's products require precision machined components produced in small- to medium-sized quantities (300 to 5,000 parts). For one product assembly, the company had been machining precision die cast aluminum check valves on a combination lathe/mill, completing just one check valve at a time. The parts require turning, milling, drilling and tapping. The machining process was adequate, but it required too much operator attention during the load, unload, deburr and inspect sequence for each valve. Since volume requirements for the check valves were growing, and the machine was needed for other work, Knappco engineers investigated alternative ways to use their machining centers. They decided to install a Kurt Manufacturing Company (Minneapolis, Minnesota) CarvLock ClusterTower equipped with machinable jaws.

By combining setup using machinable jaws on one pallet of a twin pallet Mazak FH680 four-axis mill beside a dedicated holding fixture on the second machine pallet, output was increased significantly. The new process freed up the machine, which had previously been used solely for machining large manhole fill covers but wasn't being used to its full capacity. Productivity was increased for three machining projects without adding man hours or new machines.

"It was a case of making the most of the resources we already had," reports Don Burgher, check valve and manhole fill cover team leader. "The Kurt CarvLock ClusterTower setup helped us add capacity, and it gave us a versatile workholding setup that could be changed to accommodate different parts. And it allows us to add more cluster towers if we need to add more capacity."

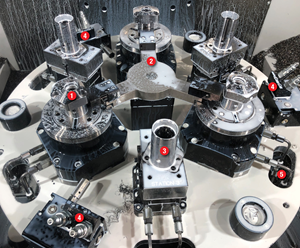

The under-used machining center now provides capacity for two projects. Officials moved the check valve machining operations onto this machine, using one of the pallets and a Kurt Vise Tower equipped with DoubleLock vises on each of the towers' four faces. Now four parts are completed at a time, allowing the operator time to load unfinished parts, unload finished checkvalves, and deburr and measure each for accuracy. Unlike the previous setup on the combination lathe/mill that completed only one part at a time and then was stopped for unloading and reloading, this setup keeps parts in the cut at all times, even during the load, unload, inspect and deburr sequence.

This machining center was said to be a good choice for the check valve work because it is flexible and powerful. With full multi-tasking machining capabilities, the center has the capacity, speed and programming flexibility for handling both projects—the larger 24- by 24- by 3-inch manhole fill covers on one pallet and multiples of the smaller 5- by 5- by 7-inch check valves on the second pallet. Fifty check valves are completed on average per 8-hour work shift with two shifts operating a five-day work week.

"We like what we've done with this system because we expanded capacity with modular components that are fully compatible with our dedicated fixtures. Our Mazak FH680 is also expandable into a Palletech system of multiple pallets for off-line load/unload using more Kurt ClusterTowers if and when we need them," says Mr. Burgher.

The entire eight-station workholding setup can be changed over for a different part run in under 5 minutes—one jaw set snaps out and another jaw set snaps in with little effort in about 60 seconds. Another nice feature of the ClusterTower system is that there are four different jaw systems available—machinable aluminum or ductile iron jaws (in three heights), an EZLock quick-change jaw plate system, and standard hard jaw plates. For the check valves, Knappco uses the four sets of the 4- by 6- by 8-inch ductile iron jaws.

"Besides being much faster than the previous setup, the operator's time is better utilized," reports Mr. Burgher. "We run this setup as aggressively as possible with high feed rates, and that's possible because the workholding is very rigid. That's why we chose Kurt. We don't have to worry about vibration or chatter because the ductile iron vise bodies damp any tendency to vibrate when aggressive operations are called for."

Related Content

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)