Simulation Software Helps Shop See, Prevent Costly Errors

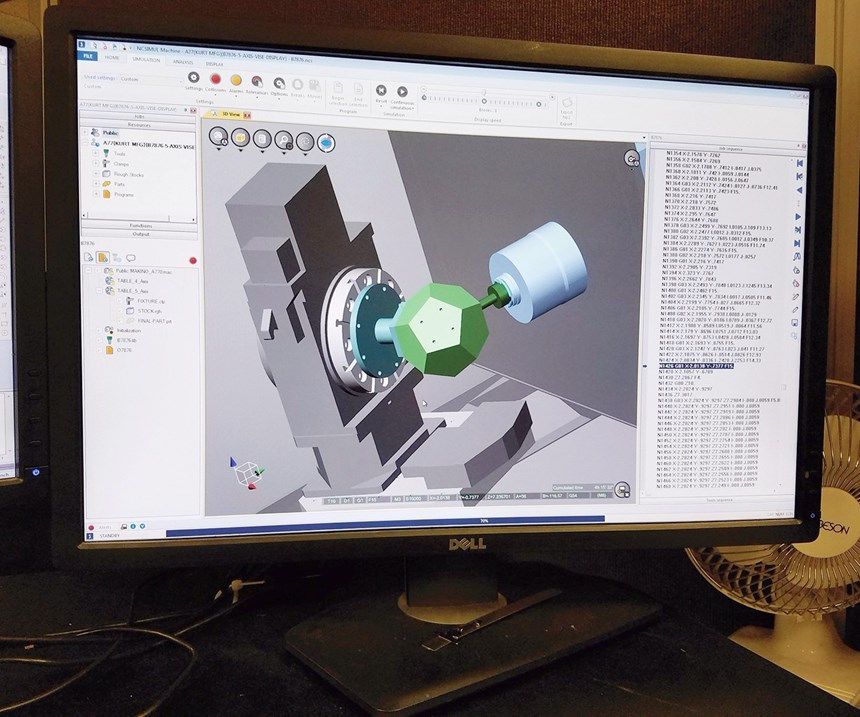

Kurt Manufacturing needed to validate CNC programs for large, expensive precision parts. NCSimul Machine simulation software from Spring Technologies saved setup time, reduced machining errors and produced accurate parts quickly.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreMaximizing machine uptime, and therefore profitability, requires contract manufacturers to set up parts quickly and machine them accurately. But experiencing errors, or a spindle or tool crash, can quickly turn a profitable job into a loss. Kurt Manufacturing of Minneapolis, Minnesota, learned how to prevent these problems and balance speed with accuracy by using simulation software from Spring Technologies Inc. (Boston, Massachusetts) to verify a program’s performance before machining.

Kurt provides a range of services, including contract machining, aluminum die casting, screw machining, welding, fabrication and assembly, as well as automation systems engineering. The company also manufactures its own product lines, including the Kurt Workholding Solutions line of vises and workholding fixtures.

Using three-, four- and five-axis machining technology in its contract work, the company produces prototype, low-volume and production quantities in short lead times to customers in a range of industries, including military, semiconductor, oil field and aerospace. “Some of our parts are $5,000 to $50,000 in value,” says Shawn Eisenschenk, manufacturing engineer.

To ensure that short runs of high-value parts are efficient, setup times need to be short and the machining needs to be free of errors. The company had been using a simulation program included with its CAM package to validate that its programs appeared free of errors, and once the program was validated, a postprocessor would translate it into G code. “We’d run our own posts and get G code,” Mr. Eisenschenk says. However, the company realized that the CAM system’s pre-G-code simulation did not always accurately show the positioning and movement of the actual machine and tools in use. If the G code generated unexpected machine motion or other errors, the problems might not be apparent until the machine ran the part, even though the program appeared to be error-free in the CAM simulation.

To resolve the issue, Kurt acquired NCSimul Machine simulation software from Spring Technologies and installed it on its machining centers, which include an Okuma unit and Makino A77s, as well as Doosan and Mazak machines.

NCSimul Machine enables users to simulate, verify, optimize and review machine programs based on the characteristics of the specific parts, tooling and machine tool involved. Three-dimensional graphics help users avoid machining crashes, while algorithms and embedded process-based knowledge optimize cutting conditions. “The graphics are very good,” Mr. Eisenchenk says. “We can bring in our exact fixturing, exact tools and exact machines.” The software can reduce time spent on debugging programs; eliminate risk of spindle collision, tool breakage and scrap; and improve cycle times and process efficiencies.

The simulation software provides machining verification in three steps. First, it investigates and corrects coding errors. Then it simulates to locate collisions and correct motion errors. Finally, it validates the part cut and machining result.

“We are mainly looking for any moves in the G-code program that might be different than what the CAM software saw,” Mr. Eisenschenk says. “Through NCSimul, we get exactly what the machine is seeing or reading. The software shows us any over-travels or mistakes where a program might have gouged or run through a part, or any rapid moves that are wrong but didn’t show up in the CAM system’s simulation.”

He says some of the shop’s jobs appeared to be error-free in the CAM program’s simulation, but NCSimul showed that the programs would result in collisions. In some cases, “We’ve seen that we might have hit or machined off a clamp that we didn’t see in the CAM software,” he says.

Kurt does not use NCSimul’s cycle-time optimization feature on its short runs, but the shop has found that it works well for some of its other jobs. “We did use it on some jobs where we were cutting down our cycle times, and it clearly showed the rapid paths,” he says. For example, he says that the software enabled the company to index the rotary and move all axes together during tool positioning on an all-terrain vehicle (ATV) crankcase it makes, reducing the cycle time by 10 to 15 percent.

According to Mr. Eisenchenk, the economic justification for implementing NCSimul software at Kurt is clear. “If you have a $20,000 part in there and you scrap it out, you can pretty much buy the software with that one scrapped part,” he says.

Related Content

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)