The Right Fit Is In The Fixtures

Custom engineered workholding fixtures are key to the effectiveness of an unusual Automated Production System (APS) recently installed at Kurt Manufacturing. It helps that one of this company’s specialties is custom engineered workholding fixtures.

Share

Most shops know Kurt Manufacturing for its extensive line of machinists’ vises. If you have a machine tool and need a vise for rigid workholding, Kurt’s catalog most likely includes a product to fit the application. These standard products are a big part of the company’s business. This part of its business, however, faces the most pressure from the so-called low-cost producers overseas. On one hand, having components or entire products manufactured offshore is an attractive option (or compelling necessity) for any company striving to maintain competitive pricing for its product lines. On the other hand, no matter where production takes place, Kurt has to compete with knock-off versions of its standard products from other off-shore producers.

A recently installed Automated Production System (APS) is helping the company get an upper hand on both sides of this issue. With its flexibility and productivity, this APS enables the company to produce vise components at a cost that helps it forego the off-shore sourcing option. The system also enables the company to be price-competitive with the import knock-offs while achieving an advantage in product quality and durability.

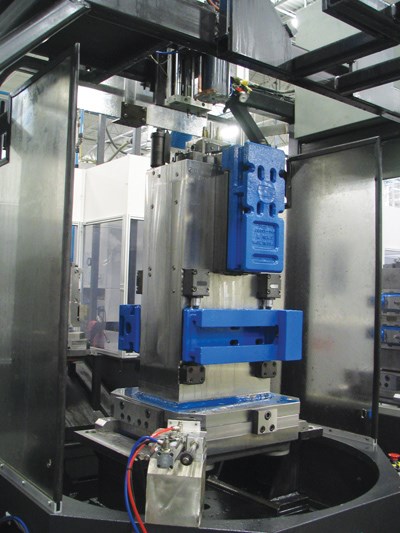

This APS, located at the Minneapolis manufacturing facility into which Kurt moved only two years ago, is unusual in its hybrid design. It is an L-shaped configuration in which the main leg consists of a Mazak Palletech FMS built around four HMCs. One of the Palletech’s two load stations is tended by a robot that also serves a “branch line” consisting of two surface grinders, a heat-treat station and a mid-sized VMC. Although the Palletech system is a fairly standard installation of that builder’s technology, the branch line is a one-of-kind arrangement developed by Kurt’s engineering staff for finishing the machined parts. The entire APS operates as a complete, integrated cell that allows parts to enter the system as pre-painted castings and leave as assembly-ready components.

Effective Workholding Is Critical

The APS was a massive undertaking for the company. The fact that the planning, construction and prove-out of the system were completed during an extreme economic downturn adds to the impressiveness of this accomplishment. The project certainly put the company’s engineering staff to the test. Planning started in 2008, about a year before installation began. The goal was to automate production of components for Kurt’s eight best-selling vise models (about 35 different part numbers). Kurt’s engineering staff, led by manufacturing engineering manager Steve Tschida, developed the overall concept and plan for the APS. However, key suppliers and local systems integrator PRI Robotics were instrumental in refining and working out the details. There was a lot to learn and a lot to figure out. “We were surprised by what we didn’t know,” says Dave Schmidt, one of the design engineers involved in the project.

One of the most important challenges was designing workholding fixtures. According to Mr. Tschida, this challenge was critical on several levels. Effective workholding was the key to consistent, quality machining; reliable robotic loading and unloading; flexible scheduling to meet product mix demand; and the integration of diverse manufacturing processes.

The upside of this challenge was the opportunity for Kurt to showcase its own product lines and workholding expertise. “We wanted to manufacture these vises using as much of our own product and expertise as possible,” Mr. Tschida says. “We utilized standard Kurt workholding, custom engineered workholding, the DockLock and other engineered systems to put this cell together. In short, we wanted to make this a display of our workholding capabilities to current and prospective customers.” As it turned out, Mr. Tschida reports that more than half of the fixture units required custom engineered workholding solutions.

Fortunately, providing such solutions is one of Kurt’s specialties. Although not as well known as its catalog items, this service is a growing part of the company metalworking business. “Applying our custom engineering expertise to the peculiar workholding requirements of this system was a great exercise of the skill and know-how involved,” says Steve Kane, global sales and marketing manager at Kurt. “It was also a great way to demonstrate the results.” In fact, some of the solutions for this APS are potentially new products that the company can commercialize. The rotary coupler that allows certain fixture towers to be charged hydraulically in the automatic mode is a prime example.

The automatic rotary coupling device also exemplifies points of larger significance. It shows that highly effective automation often relies on inventive solutions to the specific requirements of the application. Rarely can a “cookbook” approach maximize an automated system’s effectiveness. It also highlights the importance of these engineered solutions in creating effective workholding.

Rotary Coupling Accomplished

The automatic rotary coupling device enhances the inherent productivity of the Palletech FMS, which represents the main machining capability of the APS. This system consists of four Nexus HCN6000 horizontal machining centers. These are 50-hp, 50-taper machines with 10,000-rpm spindles and 1,500 psi through-spindle coolant delivery systems. Each machine has a 330-station tool hive. A Renishaw OMB probe on each machine provides automatic in-process inspection.

These machines are served by 36 pallet stocker stations and a pallet shuttle that runs up the middle of the system. The cell controller automatically prioritizes and schedules the order in which pallets will be processed (any machine can handle all of the operations required for each pallet.) At one of the load stations, fixtures are robotically loaded and unloaded. Manual loading and unloading occurs at the other station.

According to Mr. Tschida, Kurt selected this system because the Palletech technology was considered the most reliable and economical offering available with the machining capability required for the application. The well-develop cell control technology was also an important feature. Northwest Machine Technologies, the Mazak dealer in the Minneapolis area, worked closely with the engineering staff to spec the system and facilitate its installation, which commenced in July, 2008.

Of course, designing appropriate workholding fixtures for the pallets was a concern addressed early by the Kurt engineers. Providing for robotic loading and unloading at one of the load stations was essential to the mission of the APS. The robot serves as the “automated interface” between the Palletech system and the finishing line. The robot also handles the heaviest workpieces processed on the APS (typically vise bodies that weigh as much as 75 pounds) to ease the burden on operators at the manual stations.

The Palletech system is equipped with 36 pallets, one for each of the stocker stations. Each has a different arrangement of workholding fixtures. Seven of these fixtures are designed for robotic loading and unloading. Whereas the operator activates the clamping devices on the manually loaded fixtures, the engineers wanted to automate this process for the robotic fixtures. The rotary coupling device allows this to happen. It works like this:

Hydraulic connectors are located at the top of the fixture tower and centered for consistent orientation when the fixture is positioned in the load station. The rotary coupling unit is mounted overhead on the load station’s tubular framing. Upon approach to the load station, the robot sends a signal to the coupling device. The coupling device moves down to the top of the fixture and mates with the corresponding hydraulic fittings, which engage and lock themselves to complete the hydraulic connection to the fixture.

Most of these fixtures have two hydraulic circuits to control certain clamping pistons separately. This allows the fixture tower to release its workpieces on one side at a time. Generally, mounting units on the fixture use spring-loaded plungers to hold parts safely until removed by the robot. (The same plungers allow the robot to insert parts for the next machining cycle. Re-activating hydraulic pressure then clamps the parts securely for safe, rigid machining.)

Mr. Schmidt, who is responsible for the design of the coupling devices, notes that the fixture’s rotary capability is a key innovation. “This lets the hydraulic coupling remain in place while the fixture rotates in the station so each side of the fixture is accessible to the robot. The status of each hydraulic circuit remains unchanged during rotation,” he says. Maintaining this connection avoids time lost to de-coupling/re-coupling each circuit and prevents contamination of the hydraulic lines. All of the hydraulic fixtures are designed to operate at a uniform pressure rating (3,000 psi), which provides adequate clamping pressure without distorting the parts.

Mr. Schmidt says the design incorporates features that make this rotary coupler applicable to standalone machining centers. For example, the rotary coupler can be configured for fixtures with two, four or more sides. It allows some play between the rotary coupling device and the fixture to accommodate slight wobble of the fixture while rotating.

When the fixture is ready to depart the load station, the robot sends another signal to the rotary coupling device, which then draws upward and away to release the hydraulic connections. The pallet transfer unit on the Palletech retrieves the fixture and takes it to either a waiting machine or a pallet stocker station to await its turn in the work schedule.

The Finishing Line

The strategic importance of workholding fixtures also stands out in the finishing line that branches off the Palletech system. This part of the APS consists largely of pre-engineered technology that was readily deployable to Kurt’s application. However, the finishing line had to be designed from the ground up.

Kurt engineers worked closely with PRI Robotics to develop the branch line. Kurt provided the basic concepts for the line’s configuration and the placement of various production equipment and pallet stations. The integrator refined the concepts and supervised construction and installation of the line.

PRI also developed the robot program methodology that controls the branch line and interfaces with the Palletech’s control system. This software handles all of the branch line’s machine scheduling, pallet tracking and communication between robot and machine tool controllers.

The finishing line is built around a Fanuc R2000iA/165F six-axis robot. It travels the length of the branch line on a servo-controlled robot transporter unit (RTU) riding on 57 feet of dual-rail track. Essentially, one side of the branch line is the production side, while the other side (next to a main shop aisle) is the non-production side. Two Chevalier Smart B2460II CNC surface grinders and Kurt’s custom-built heat treat station are lined up next to one another on the production side, whereas the VMC (a Mazak Nexus 510C) is stationed at the end of the robot track and adjacent to the heat-treat station. The standard pallet used on the finishing line measures 20 by 24 inches.

The non-production side of the branch line serves as a staging area for incoming raw parts, a storage area for empty fixtures and a queuing area for loaded fixtures awaiting machine availability. Some of the racks on this side are multipurpose. For example, empty fixtures are stored in compartments under the platforms, on which palleted fixtures are stationed for loading and unloading. Operators can walk up to the non-production side from the shop’s aisle. It is also accessible to a forklift for exchanging wooden pallets that carry raw parts into the cell.

Not all queuing stations and racks for grippers are on the non-production side. Several are located next to the machines on the production side where the robot has the shortest distance to retrieve the next gripper or pallet for machining. Several grippers ride along with the robot transport unit so that they are always within reach.

The branch line makes prominent use of Kurt’s DockLock zero-point clamping system. The DockLock system provides high precision locating and clamping for the grinders, which are loaded and unloaded by the robot. The same clamping system is used in the VMC, which is also loaded and unloaded by the robot.

Activity on the finishing line is varied and interesting. The robot has two broad duties. One is to unload the wooden skids of incoming raw castings. The other is to tend the grinders, heat-treat station and VMC.

When a palleted tombstone fixture arrives at the Palletech load station, a radio frequency identification (RFID) unit on the pallet notifies the robot which specific parts are needed. This information ensures the robot retrieves incoming castings from the correct skid station. Quick-change components and dedicated grippers allow the robot to accommodate the variety of incoming castings on different skids. The skids hold multiple layers of castings separated by rigid slip-sheets. A vision system helps the robot, find parts randomly arrayed in each layer. (A special gripper allows the robot to remove an empty slip-sheet to access parts in the next layer.) The correct number of raw parts is loaded on a dummy pallet and transported to the load station, where they will be inserted in the clamping units on the arriving Palletech fixture.

Completed parts unloaded by the robot are taken to the heat-treat station, where they are induction-hardened to approximately 50 Rc. They are then moved to a load station to be loaded on an appropriate pallet as determined by the robot. When the operator is finished loading the pallet, the robot is queued to retrieve the pallet and move it through the various machining operations. When the sequence is completed, the robot brings that pallet back for another load/unload cycle.

Ramifications

Benefits of the APS extend beyond the automated production of vise body components, Mr. Tschida says. For example, the robot has freed up shop personnel who have been redeployed to the formerly outsourced production of locking nuts and other accessories. Likewise, older existing equipment moved from the previous facility could now be arranged in dedicated cells. Because the APS represents a majority of the shop’s machining capacity, the mix of parts moving across other equipment is greatly reduced, thus facilitating the use of dedicated cells for high-throughput production. The APS has also freed sufficient floor space to pull some turning operations back in house.

The lesson not to be overlooked here is that a company committed to keeping manufacturing operations in the United States can do so, provided it has the will, commitment, investment and know-how. Kurt Manufacturing apparently made good use of all of its resources, especially its capacity to be creative to and inventive with its custom engineering workholding solutions. This capability was undoubtedly an advantage in the design and implementation of this APS, given that workholding considerations are critical in any automated production strategy.

Ultimately, of course, Kurt’s customers who are looking for workholding solutions for their own automated machining lines will benefit, too, even if that benefit is limited to drawing inspiration from this example.

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)