New Jaws Speed Change-Over for Short-Run Jobs

This shop found that a quick-change jaw system reduced 80-minute change-over times to just 8 minutes.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Addressing workholding setup time became necessary for Modern Manufacturing and Engineering (MME) as its volume of work increased. Many of the company’s jobs were short runs, with setups that needed to be changed every two to four days. By investing in a quick-change jaw system from Kurt Manufacturing (Minneapolis, Minnesota), MME was able to decrease workholding change-over time by 90 percent while lowering machining costs.

Headquartered in Brooklyn Park, Minnesota, MME provides precision, custom-machined components and assemblies for aerospace and military applications. Its 35 Mazak CNC machining centers are equipped with automated pallet systems capable of complex machining operations with spindle speeds ranging to 25,000 rpm. Many of these machines have 120-station toolholders that deliver 3 second chip-to-chip robotic indexing. The machines are designed to be fast and accurate to tolerances of 0.0002 inch and are used by MME for machining aluminum, stainless steel and similar high-performance metal components measuring 1 square foot and smaller.

When MME’s work volume began to grow, the company realized it would need to improve production speeds—not by increasing machining speeds, but rather by improving workholding setups. For instance, it took about 80 minutes to change over eight pairs of standard jaws on the company’s twin-pallet horizontal machining center equipped with two vertical, single-station towers. That time doubled when changing jaws on twin-station towers.

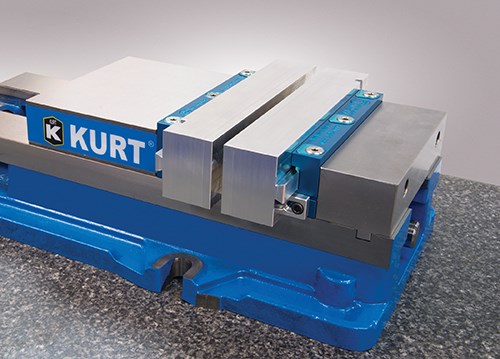

As a long-time user of Kurt vises and Cluster Towers, MME had a substantial investment in its workholding, so it wanted to preserve that as much as possible. Investigating Kurt’s numerous new products for maximizing workholding efficiency, the DoveLock quick-change jaw system stood out as a great way to improve setup time with MME’s existing vises and towers while adding versatility for handling frequently changing jobs.

“Soon after trying out a DoveLock system, our machinists saw how much faster they could change jobs. They requested additional sets, quickly leading to the complete adoption of the DoveLock system,” says Hue Van Lien, president and owner of MME. “We’ve installed more than 350 DoveLock sets throughout our shop on the vises and towers used on both horizontal and vertical machining centers.”

DoveLock jaw system in the towers reduced the 80-minute change-over time to just 8 minutes. That savings, when implemented across MME’s three dozen machining centers, was a huge boost for the company’s lean manufacturing initiative.

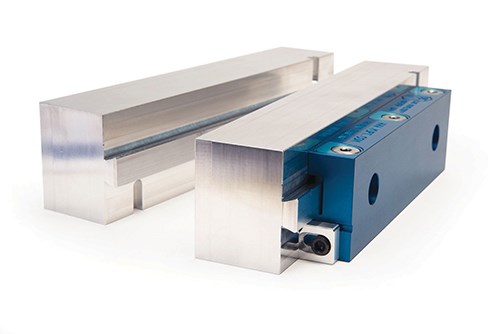

The two-component DoveLock system consists of two master jaws with four low-head-socket cap screws and a 5/32-inch hex “T” wrench as well as a machinable jaw set consisting of two aluminum jaw plates. It is available in both inch and metric sizes and is precision machined from 6061 aluminum to ensure accuracy for highly precise and repeatable setups.

The DoveLock itself consists of a master jaw with built-in, specially designed dovetail quick clamps. The quick clamps are designed to precisely hold and lock into position the quick-change machinable jaws. In the initial setup, each master jaw has two bolts that fasten to the stationary movable jaw of any standard 6-inch Kurt vise or standard Kurt Cluster Tower. Once the master jaws are in place, the machinable jaws locate precisely with the master jaw and quickly lock up using the machinable jaw’s three hex head bolts.

DoveLock’s machinable jaws are designed to easily swap out for future jobs simply by loosening the three quick-clamp bolts at the top of the master jaw and sliding it forward at an angle or sideways out of the master jaw. The machinable jaws can be rotated 180 degrees and machined on both sides for holding two different parts. Without measuring, DoveLock’s workstop, located on the master jaw, enables quick and repeatable location accurate to ±0.001 inch. To handle a full range of part sizes, interchangeable jaws are available in 6-, 7-, 8- and 10-inch widths.

Using the DoveLock, MME is able to produce thousands of parts in different configurations and quantities each month, Mr. Van Lien says. Operating two shifts a day, in a six-day week, he says the company frequently maxes out a machine’s capabilities by machining more than 200 inches per minute, which it could not do before switching to the DoveLock system.

“The DoveLock system gives us the needed versatility to move quickly from one job to the next. The vises and tombstones stay in place on the machining centers. Only the jaw plates are changed, saving us many man-hours a day across our entire machining facility,” Mr. Van Lien says.

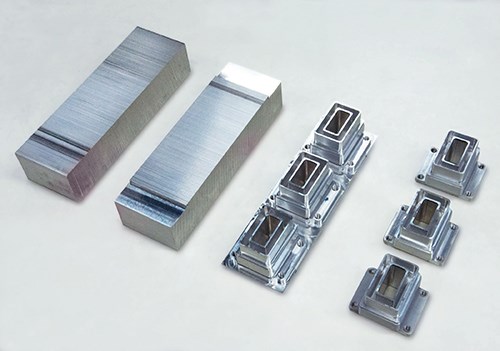

An additional advantage of the DoveLock is that it enables MME to mill into the changeable jaw plates using the full volume of jaw material. This is something the company couldn’t do with its old jaw setups because it had to avoid the two cap screws when machining a feature or pocket into the jaw plate. The extra area of metal enables the company to design workholding setups it previously couldn’t.

The DoveLock jaws also give MME the ability to machine multiple steps on the same pair of jaw plates. By rotating the jaw plates and machining different steps on both sides, fewer jaw plates are required for those jobs requiring different steps. The DoveLock’s machined jaws’ precision enable MME operators to clamp wider parts into two side-by-side sets of jaws.

“The DoveLock quick-change jaw system provides a perfect grip, precise repeatability for very accurate and consistent machining,” Mr. Van Lien says. “The system enables us to utilize our machines to their full capabilities while maintaining consistent part quality.”

Related Content

Building Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)