Fixtures Facilitate Transfer Line Automation

Replacing fixtures in an automated transfer line with robot-integrated models from Kurt Manufacturing helped this tier one automotive manufacturer eliminate issues with part distortion and expand production.

Share

After more than two years of deep recession, the economic outlook still appears bleak to many. However, workholding supplier Kurt Manufacturing says it sees signs of life in the automotive sector. Expecting production to ramp up during this year, a Tier 1 supplier recently placed a $250,000 order for custom fixtures designed to facilitate automation. The new fixtures have reduced cycle time, improved accuracy and increased production output, leading the company to plan a second order to accommodate additional demand.

"We are especially excited with this order because it confirms that the automotive industry is rapidly improving," says Jeff Lenz, business unit manager of Kurt Engineered Systems. "Customers like this Tier One supplier see good times ahead and are investing in the latest equipment to be on the leading edge of the recovery."

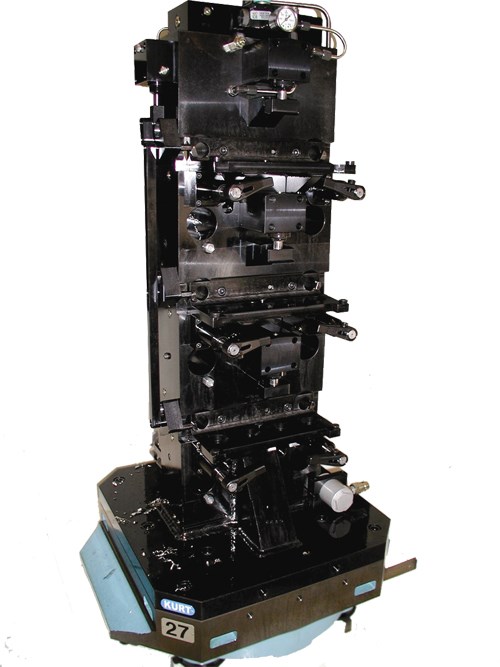

The initial order called for 10 custom workholding fixtures to be integrated with robot arms into an existing automated transfer line. The line’s eight HMCs are used for precision machining of automotive bearing housings. These parts consist of two 10 × 8 × 5-inch, cast iron pieces that must be connected with a flatness tolerance of 15 microns across the mated surface. Each robot arm serves two machines, and each machine has two associated fixtures. At each station, the HMC machines workpieces in one fixture while a robot arm unloads finished parts from the second before reloading it with a raw casting.

Automating the line has enabled the company to increase pro-duction from 1,800 assemblies per day to approximately 4,500 in one 8-hour shift. Key to the success of this project are custom features incorporated into the Kurt fixtures. For example, each includes a pass-through "window" that allows cutting tools to access all sides of the part and machine it complete in a single clamping. In contrast, the previous fixtures required batching—that is, performing a given operation on a batch of parts before changing the fixture to accommodate the next operation.

To accommodate the robot arms, the fixtures include pre-loads for each part position. These pre-loads consist of ball detents and other mechanical elements that keep the part from falling out of the fixture when the robot releases it. This not only eliminates the need for the robot to wait for the part to be clamped before moving away, but also prevents the robot from interfering with the clamping process.

Also facilitating automation are built-in sensors that communicate the status of the fixture and parts to avoid misloads, pressure loss or other problems. Proximity sensors verify that parts are properly placed and clamped, while pressure sensors continuously monitor hydraulic pressure during machining. All data is fed back to the robot arms and machine controls wirelessly, eliminating the need for connecting cables or other such devices.

However, reducing cycle time wasn’t the company’s only concern. Its previous fixtures also made it difficult to attain consistent part quality. Namely, clamping often distorted the bearings, causing abnormal operating noise and premature wear. The company recognized that ramping up production would exacerbate the problem and inhibit efforts to increase output on the transfer line.

To address the issue, Kurt incorporated work supports into the new fixtures along with traditional hydraulic spring clamps. Once contact is made with the part, each support is held in place with about 2,000 pounds of force to avoid moving or distorting the part. Additionally, independent control of the clamps and work supports enables the company to determine when each support touches the part and when clamping pressure is engaged. This facilitates testing and changing the sequence of how a given part is supported and clamped.

The location of the supports and clamps as well as independent control has also improved accuracy. While the previous fixtures were limited to a tolerance of 30 microns, the new Kurt system can hold parts flat to less than 12 microns while maintaining a 1.67 Cpk level.

As a result of its success with the custom fixtures, the customer says it plans to expand the transfer line with more machines and fixtures to support them.

Related Content

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)