Norgren Introduces One-Size-Fits-All Soft Jaw

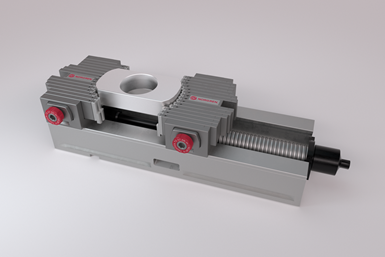

Norgren’s Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the CNC machining process.

Share

Norgren has announced a new workholder — the Adaptix Soft Jaw — which is the first product in a new portfolio.

The Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the CNC machining process. According to Norgren, it was specially engineered to be a one-size-fits-all alternative to standard, single-application aluminum soft jaws.

“Single-application soft jaws require a significant amount of time, skill and raw material to construct, even before a single part is milled,” says Tom Wood, senior director of growth initiatives at Norgren. “We saw an opportunity to solve several machining problems with just one tool, and so we designed the Adaptix Soft Jaw to grip nearly any part with comparable repeatability and clamping force as single-application soft jaws.”

The Adaptix Soft Jaw’s adjustable fingers and interchangeable tips are made out of a variety of different materials to match the milling needs of a particular part. The fingers mold into place, conform to the shape of the target part and are locked in place. This configuration process reportedly takes minutes instead of hours, as with traditional soft jaws. The soft jaw fits directly onto a vise; it is currently compatible with Kurt and Schunk brand vises, with other vise compatibility planned in the near future.

The Adaptix Soft Jaw currently has limited availability and is offered with special pre-order pricing.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

.jpg;maxWidth=300;quality=90)