Autodesk, Inc.

One Market Street

Suite 500

San Francisco, CA 94105 US

415-507-5000

na_mfg@autodesk.com

autodesk.com/make

About Autodesk, Inc.

Autodesk is a global leader in design and make technology. With expertise across architecture, engineering, construction, design, manufacturing, and entertainment, we help innovators everywhere solve today’s pressing challenges.

IS THIS YOUR COMPANY?

Video Gallery

How to make tea at our Birmingham Technology Centre 🫖 #3dprinting #engineering #teatime

Cosmic Robotics Aims to Revolutionize Solar Farm Construction

As aging infrastructure and labor shortages challenge the construction industry, innovative companies are stepping up to develop ...

They are NOT the same. #concrete #cement #architecture

What’s the greatest architectural city in the world? Weigh in below! #architecturelovers #paris

As Seen On Modern Machine Shop

Autodesk, Inc. Supplies the Following Products

- CAD/CAM for Additive Manufacturing

- CAD/CAM Software

- CNC Software, Stand-alone

- Engineering Analysis & Simulation

- NC Program Optimization

- NC Verification

- Nesting Software

- Part Design Software

- Post Processors, Stand-Alone

- Quality Documentation

- Tool Design

Trade Names Offered by Autodesk, Inc.

- Fusion with FeatureCAM

- Fusion with PowerShape

- Moldflow

- Fusion with Netfabb

- Fusion with PowerInspect

- Fusion with PowerMill

- Autodesk Fusion

Editorial, News, and Products

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

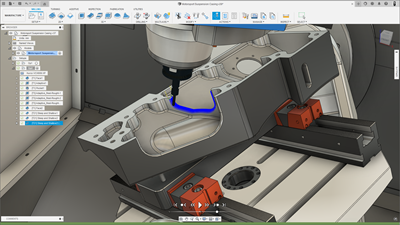

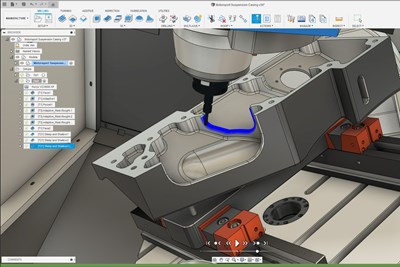

Autodesk CAM Software Simplifies Part Programming

IMTS 2024: Autodesk Inc. is exhibiting its complete portfolio, including Autodesk Fusion, a cloud-enabled software that provides AI-driven CAM programming tools, multi-axis machining strategies and more.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Formnext Chicago Secures Premier Exhibitors

The newly announced additive manufacturing show, Formnext Chicago, will take place at McCormick Place in spring 2025.

-

Autodesk Fusion 360 Software Enables Generative Additive Manufacturing

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

-

Autodesk Fusion 360 Unifies Design, Manufacturing Process

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

-

Autodesk, ModuleWorks Form Strategic Partnership

Autodesk will use ModuleWorks’ toolpath technology in its Fusion 360 software.

-

Autodesk Acquisitions Support Digital Factory Concept

Autodesk acquires Prodsmart, software provider for optimizing manufacturing processes with automation and digitization, in latest move to support digital factory connectedness.

-

Premier Prototyping Machine Shop Thrives on Software

Front-office automation and a discerning approach to work-free time for skilled CAM programmers to do what they do best.

-

Generative Design for Milling Lightweights EV Motorbike Part

Autodesk’s Fusion 360 generative design function can create mass-saving solutions for three-axis milling and other conventional manufacturing processes.

-

Fusion 360 Leaps Into the Cloud with Extensions and Forge

At its Autodesk University 2021 conference, Autodesk announced upcoming features for Fusion 360 such as generative design updates and integration with the company’s cloud-based Forge platform.

-

Use CAM Templates to Automate Programming — The One-Person Shop #3

Capture knowledge and speed programming time by equipping the software to generate some of the routines that are used routinely.

-

Shifting From On-Machine to Offline Programming

In the midst of learning to program its CNC milling machines offline and the promise of using that experience to transfer more work to its Swiss-type lathe, an Ohio job shop is changing its company culture and taking on more complex work.

-

Sandvik Coromant and Autodesk Partner for Increased Utility

Sandvik Coromant and Autodesk have partnered to solve issues in CAM. Their first solution is to present Sandvik Coromant tool data within Autodesk Fusion 360.

-

Autodesk Fusion 360 adds PowerMill Technology and More

Autodesk’s Fusion 360 receives a major functionality upgrade with the addition of PowerMill, PowerShape and PowerInspect technology – offering more technology and better value.

-

A Convergence of Construction and Manufacturing

Digital tools for the construction industry have their counterpart in applications for manufacturing. Manufacturing companies should keep an eye on how the construction industry is managing the digital transformation.

-

Generative Design Generates New Interest in a Range of Manufacturing Options

New developments in generative design can help companies make better decisions about part design by including manufacturability as a key value. CNC milling, for example, not an additive process, might come up as the better choice for making a complex part.

-

What This Seat Bracket Says About the Future of Automotive Manufacturing

General Motors created a 3D-printed version of a seat bracket using generative design tools. This technology pairing will influence how cars are brought to market in the future.

-

The Little Shop That Could (with the Help of a Tapping Arm)

A pneumatic tapping arm enabled a small job shop to complete a challenging job in a week that would have taken other shops months to finish.

-

Silicon Valley Firms Point to Digitalization as a Golden Opportunity for Manufacturers

This report summarizes the findings from the sources of many transformational technologies that focus on digitalizing the manufacturing industry.

-

Autodesk Appeals to Doers and Dreamers

Autodesk software supports practical applications in the machine shop as well as imaginative creations in the inventor’s studio.

-

Still More to See at IMTS

With over 2,400 exhibitors on 1.3 million square feet of floor space, IMTS 2018 has the broadest display of technology ever.

-

Your Path to Smart Manufacturing

Whether you are looking for creative new products, to deepen your current skillset or to find new industry trends Autodesk manufacturing software can help.

-

Additive Manufacturing Trending

From the IMTS Technology e-Newsletter (Sponsored)

-

Manufacturing News of Note: July 2018

Successful tests of computer-aided manufacturing with barrel-nose cutters, Siemens PLM switches to new distribution regime for NX software and other industry news.

-

Make Your Manufacturing Smarter

Autodesk Fusion Production software combines production scheduling, job tracking, and machine monitoring into a single, complete, cloud-based tool.

-

Make Parts Faster with Automated CAM

Instead of having to program a machine stage by stage, the operator can program it using everyday shop terms, such as ‘turn’, ‘bore’, ‘bolt’, etc.

-

New CAM Software Offers Powerful Editing Tools

PowerMill is Autodesk’s CAM solution for high-speed and five-axis machining.

-

Autodesk Introduces PowerMill 2019 and Fusion Production at Its Smart Manufacturing Celebration Event

Autodesk’s Smart Manufacturing Celebration showcased enhancements to PowerMIll 2019, the latest release of its flagship CAM programming systems, and demonstrated the integration of production scheduling, job tracking and machine monitoring.

-

CAM Software Includes Tools for Hybrid Manufacturing

Autodesk’s PowerMill 2019 CAM software includes developments that are designed to enhance existing functionality for high-efficiency machining.

-

Racing Toward the Intersection of Design and Manufacturing

Driven by software automation and with all engineering and production under one roof, this drag racing organization provides a striking example of a machining operation with data at the center.

-

What’s Your Place in the Future of Making?

Autodesk’s annual user conference shed light on a machine shop’s place in an era of democratized, automated product development and merged design and manufacturing workflows.

-

MakeTime Launches Shop Advantage Program at Top Shops Conference

The program will give machine shops access to special offerings for cutting tools, CAD/CAM software, computer hardware, CNC machine tool and manufacturing equipment financing and more.

-

CAD/CAM Software Gets Streamlined User Interface

Westec 2017: Autodesk will present the 2018 versions of its major CAD/CAM software including PowerMill.

-

Manufacturing News of Note: July 2017

A big R&D agreement looks at additive for structural airplane components, Autodesk appoints a new president and other industry news.

-

Hiring, Training and Supporting the Workforce in School and on the Job

Virginia’s Rolls-Royce Crosspointe plant shares its strategies for attracting, hiring and supporting its workers, while Danville Community College excels with its integrated machining education model.

-

Autodesk Appoints New President, CEO

Andrew Anagnost has been with the company since 1997.

-

CAM Software Simplifies Interface for Complex Parts

Amerimold 2017: Autodesk will demonstrate its PowerMill CAM software and its Moldflow mold simulation product.

-

CAM Software Gets New Look and Feel for Simpler Use

Now part of Autodesk, PowerMill 2018 features a radical new look and feel to simplify the experience for new and existing users.

-

Promise Seen in the Shift from Portfolio to Platform

Autodesk seeks advantages from integration that stand-alone software solutions are challenged to provide.

-

Webinar: Practical Tips for Unattended Machining

A free webinar presented by Autodesk October 19 will address tips and techniques to help shops begin machining unattended.

-

Software Solutions for Design, Simulation, Additive Production

Autodesk’s Netfabb software is designed to take additive manufacturing beyond prototyping and plastics to create production-grade parts at scale.

-

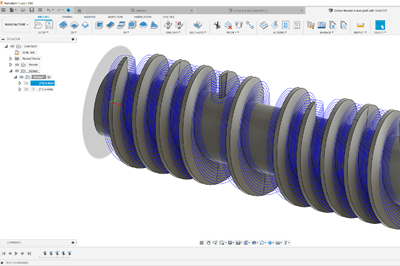

An Improved Method for Machining Blisks

A software designer and a tool maker collaborate on a system for machining blisks that focuses on the point of contact between the workpiece and the cutting tool.

-

Don’t Sweat the Setup: Probing the Position of Complex Workpieces

This manufacturer uses a software tool to tailor the machining program to the location and orientation of each contoured part.

-

How Sensors Add Value

What practical role do sensors play in a machine shop?

-

Video: Accelerated Blisk Milling

CAM and cutting tool companies develop a process for machining a titanium bladed disk in less than half the conventionally expected cycle time.

-

Winter Blahs Setting in? Watch this Video!

Andrew McAfee's presentation at the Opening General Session of Autodesk University in December made me feel pretty darn good. His message was simple: Technology, especially computer software, has done much to improve the human condition. The recording of his presentation is likely to lift your mood, too, if a dreary, post-holiday winter day is dragging you down.

-

Sophisticated Software for Solid Gear Design

Whether your computer platform is standalone or part of a suite, desktop or on the cloud, there’s a gear design package developed specifically to meet your needs.

-

Adaptive Machining Makes a Robot More Productive

This system for machining and polishing turbine blades shows the value of software for inspection, toolpath calculations and adaptive machining working together.

-

CAM for Moldmaking Simplifies Rib Programming

Delcam’s PowerMill programming software for five-axis and high-speed machining offers new developments for moldmaking, including improvements to the Vortex high-efficiency area-clearance strategy, enhanced collision checking, toolpath simulation and verification, and a new module for machining ribs into tooling.

-

2014 Autodesk Inventor of the Year: Gear Manufacturer in IN

Once a year, members from the Autodesk Manufacturing Community choose among the past year's monthly “Inventing the Future” honorees to select an Autodesk Inventor of the Year. The 2014 winner was recently announced and it is ITAMCO, a custom gear manufacturer based in Plymouth, Indiana.

-

Houstex 2015 Preview Slideshow

Click through the slideshow to see a selection of technologies to be displayed at Houstex in advance of the February 24-26 trade show.

-

Developing the Cover's Cool Caliper

Here’s how the September cover of Modern Machine Shop came to be.

-

CAM Programs Emphasize Integration

Autodesk will exhibit its range of CAM software built on the HSM CAM kernel, designed for generating efficient machining code and enabling the manufacture of high-quality finished parts while saving time and resources, the company says.

-

QFS Keeps Its Customers Moving With Integrated CAD/CAM

Quickly updating tool paths to remachine die surfaces enables this shop to provide short runs of prototype formed sheet metal parts. This fast response to engineering changes and design adjustments helps its customers adhere to tightly scheduled vehicle launch programs. QFS relies on integrated CAD and CAM software to make this happen. In this case, the software of choice are PowerShape and PowerMill from Delcam.

-

Video: Keeping 3 + 2 Machining in the Clear

When using a five-axis machining center for 3 + 2 (positional) machining, the programmed tool path must be checked carefully to avoid collisions and optimize results. This video shows how Delcam PowerMill’s new Dynamic Machining Control improves this process.

-

Hands-On Experience Helps Autodesk Innovate

During a recent trip to San Francisco, Calif., Senior Editor Chris Felix from sister publication Production Machining got a chance to visit Autodesk’s new Pier 9 facility. There, he learned about the commercial availability of Inventor HSM, an integrated CAM solution for Inventor users.

-

Keeping 3 + 2 Machining in the Clear with PowerMill’s Dynamic Machine Control Toolbar

Dynamic Machine Control helps the programmer find the most advantageous workplane orientation, cutting tool tilt angle and tool length in order to speed the process of optimizing a 3 + 2 program.

-

Delcam and Autodesk Seal the Deal

Autodesk, Inc. completed its acquisition of Delcam earlier this month. I like the synergy behind this combination.

-

Helping the Bloodhound SSC Hunt for a New World Record

This video shows how Delcam PowerMill’s Vortex machining strategy is helping to manufacture the front suspension subassembly for the Bloodhound SSC (SuperSonic Car).

-

CNC Programming in the Cloud

Autodesk CAM 360 is intended to help product designers and engineers integrate manufacturing processes into unified, collaborative workflow. Cloud-based computing, a key feature of CAM 360, powers toolpath generation, program simulation and postprocessing with “anywhere, anytime” connectivity.

-

Keeping Tabs on Robot Machining

A new website from Delcam focuses on developments in machining with industrial robots.

-

Machining with Robots

Several exhibitors at the recent EMO show in Hannover, Germany, featured demonstrations of robotic arms wielding live cutting tools such as end mills or face mills. Perhaps the most dramatic demo was presented by Delcam to showcase this CAM developer’s PowerMill Robot Interface.

-

Five-Axis Machine/Software Combo Boosts Profitability

After Superior Tool and Mold invested in five-axis machining capacity from Delcam and DMG/Mori Seiki, it realized improved quality and greater profitability.

-

High Speed Roughing Strategy Extends Tool Life

Delcam will launch its Vortex strategy for high speed area clearance, an enhancement to the company’s 2014 PowerMill CAM system for high speed and five-axis machining.

-

CNC Programming Software Maximizes Five-Axis Capability

By incorporating new CNC programming software to make full use of its new five-axis machining capabilities, Bob Lewis Machine Co. has reduced setups and programming time.

-

Software Speeds Prototype Production

Using Delcam’s PowerMill and PowerShape software enabled a prototype manufacturer to turn CAD data into a validation part in less than 24 hours.

-

Stem Solution Found In Multi-Tasking Turning Center

A small shop committed to labor-saving automation added a nine-axis turning center to machine mountain bike stems. The value of this complex machine is that it delivers a simple process. The learning curve was worth it, the owners say.

-

Integrated CAM System is Fully Compatible with SolidWorks

The 2013 version of Delcam for SolidWorks includes many of the enhancements made to the 2013 FeatureCAM feature-based programming system, and it is fully compatible with the latest release of SolidWorks.

-

Roughing Strategy Controls Engagement Angle

Vortex, a major enhancement to the 2013 edition of Delcam’s PowerMill CAM system for high speed and five-axis machining, is designed to produce tool paths with a controlled engagement angle.

-

Fully Committed to Zero Stock Machining

Milling critical mold surfaces to final size (or even a “tenth” undersize) literally leaves no margin for error. This takes absolute confidence in every aspect of the machining process, as well as absolute confidence that the results are worthwhile.

-

Creating Machine-Specific Tool Paths

A new CAM capability takes a snapshot of an individual machine’s performance characteristics and uses the information to tailor an optimized tool path for that specific machine.

-

Software Offers Data Repair, Modeling for Manufacture

The Solid Doctor feature of Delcam’s PowerShape CAD software uses automatic data repair tools and surface creation and editing options to address problems commonly encountered when translating low-precision and incomplete data.

-

CAM System Adds Roughing, Turn-Mill Strategies

The 2012 R2 release of Delcam’s FeatureCAM feature-based CAM system includes roughing and turn-mill strategies as well as enhancements for faster toolpath generation

-

Targeted Five-Axis Machining

Focusing on a particular part size range allows this shop to use a versatile type of five-axis machine tool. Five-axis machining now makes up 40 percent of the shop’s business.

-

Video: Five-Axis Machining at Padgett Machine

A job shop owner talks about five-axis machining and feature-based programming.

-

Program Wire EDM with Delcam for SolidWorks

The 2012 version of Delcam for SolidWorks includes wire EDM programming and more.

-

CAD/CAM Products Speed CNC Programming

Delcam’s CAD/CAM products feature a range of enhancements designed to speed and ease programming for CNC machines

-

Enhanced Feature-Based Machining

The 2012 version of Delcam’s FeatureCAM system is designed for faster and easier programming, more efficient toolpaths and increased machine productivity.

-

CAM System Proves Integral to Prototype Prove-out

Delcam for SolidWorks CAM software helped this engineering firm relied on to generate the complex tool paths for a prototype job that many machine shops dismissed as too difficult.

-

CAM System Adds Flowline Machining Option

The 2012 version of the PowerMill CAM system for high-speed and five-axis machining features a flowline machining option that divides the tool path between a pair of drive curves in a constant number of passes rather than having a varying number of passes with a constant stepover.

-

Inspection Software Features Quick Report Option

Delcam’s PowerInspect 2011 features a Quick Report option designed to ease result analysis and reuse of measured data for additional feature inspection.

-

Program Safe Tool Paths

The 2011 version of Delcam’s PowerMill CAM system for five-axis and high-speed machining is said to ease programming of safe tool paths with new stock-model engagement options that protect both the cutting tool and the machine from excessive loading.

-

CAD/CAM Systems Drive Efficient Porting Routines

Delcam’s PowerShape design software and PowerMill machining software help this performance racing component manufacturer meet targets for accuracy and efficiency during engine porting operations.

-

Feature-Based CAM Update

The 2011 version of FeatureCAM has a modernized interface, support for 64-bit computers, improved data exchange from a wider range of design software and new strategies across the platform, from turning to five-axis machining.

-

CAD/CAM Range for Footwear

Delcam Crispin’s design and manufacturing software for the footwear industry features updates to the 2010 LastMaker and ShoeDesign programs, plus general speed and ease-of-use improvements across the full software range.

-

Finished Molds Overnight

In the highly competitive athletic footwear market, moving from concept to design to production at breathtaking speed is imperative. Fast and efficient five-axis machining is a key accelerator in this process.

-

Delcam for SolidWorks

The company offers its full range of CAM software, including Delcam for SolidWorks as well as the 2010 releases of PowerMill for high-speed and five-axis machining; FeatureCAM for feature-based programming; PartMaker for Swiss-type lathes and turn-mill equipment; and ArtCAM for engraving and routing. Delcam for SolidWorks marks a new direction for Delcam, the company says.

-

Video: 3+2 Mold Machining at Eifel

A maker of injection molds for high-appearance-quality parts describes the machine tool, software and strategy this shop uses to apply 3+2 machining.

-

Another Angle On HSM

The savings in setup time were welcome enough, but this mold maker found that a 3+2 machining center also accelerated its use of high speed machining.

-

CAD/CAM Speeds Mold Design, Machine Tool Programming

Two features incorporated in CAD and CAM software packages from Delcam help users save time during design and machine tool programming.

-

CAD-Based Inspection Software

Delcam says the 2010 version of its PowerInspect inspection software offers easy inspection of parts, tooling and prototypes against CAD data.

-

Use The Tools That Are Available

Typically, creating holes isn’t a daunting task. However, programming, machine set up and cycle times can be prolonged when a part has numerous hole diameters. A new feature-based CAM strategy automatically determines how best to combine drilling and milling to create the holes using only the tools already loaded in a machine.

-

Five-Axis Dental Machining

Version 5 of Delcam’s DentMill includes an expanded range of five-axis machining options, including easier programming for manufacturing dental bars, implant bridges and customized abutments. Another enhancement, multithreading technology, is said to reduce calculation times for users with multi-processor computers.

-

NC-Checker For Machine Tool Verification

Using standard probing equipment, Delcam’s NC-Checker program verifies the in-process performance of a range of commonly-used machine tools. The program can be used before machining to confirm that the equipment has been set up correctly, and it also can be applied during the production run to detect any out-of-tolerance movements.

-

Parallel Processing Speeds Toolpath Calculations

Parallel computing refers to the division of programming tasks among multiple processors, or cores. Delcam says leveraging this technology has significantly reduced toolpath calculation times in the most recent version of its PowerMill CAM software.

-

CAM Software Helps Make Pastime Profitable

When shop owner Joey Klitzke began to leverage his manufacturing skills to improve his competitive edge in tractor pulls, it wasn’t long before he recognized a business opportunity. FeatureCAM software from Delcam has helped Mr. Klitzke turn his hobby into a profitable business.

-

CAM Suite Promotes Die Throughput

This automotive tool and die manufacturer had determined that remaining competitive would require reducing machining times. However, the impediment to throughput lay not in the machining end of the operation, but rather in the time spent programming complex tool paths. With fast calculation capability and a variety of strategies for five-axis roughing and finishing operations, Delcam’s PowerMill CAM package reduced programming times and enabled faster, more efficient machining.

-

Fast Mold Design, Machining

Delcam’s PowerShape CAD software and the PowerMill CAM system are said to offer fast mold design and fast machine tool programming, respectively. The fast mold design has been made possible by incorporating the Parasolid kernel for solid modeling alongside the company’s own surface modeling system.

-

CAM Package Unlocks Turn-Mill Capabilities

While multi-spindle turn-mill machines can improve productivity by enabling users to machine parts complete in one setup, fully realizing their benefits requires a CAM package that is capable of synchronizing multiple spindles. With Delcam’s FeatureCAM software, cutting tool manufacturer Parlec eliminated the time-consuming process of programming each spindle of its turn-mill machines separately before manually synchronizing them on the shop floor.

-

Getting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

-

Software Separates Shop From Competition

FeatureCAM’s feature-based programming capability and five-axis machining strategies help this shop set itself apart from the competition. In fact, the shop has increased gross sales by more than 30 percent in a few months after integrating FeatureCAM’s five-axis machining package.

-

CAM Software Helps Reduce Machining Time By 80 Percent

This company upgraded its CNC milling capability and CAM software to make use of solid models and get its components produced more quickly.

-

Mold Maker Cuts Delivery Times With CAD/CAM

Staying competitive in the automotive industry requires quick turnaround, a fact not lost on this manufacturer of foundry tooling. Upgrading to a CAD/CAM system from Delcam helped the shop significantly increase machining efficiency and reduce delivery times.

-

Video: Micromilling With a Long Tool

This video clip illustrates micromilling at a high tool L:D ratio.

-

Composites Keep A Big Machine Busy

On-machine inspection is part of the way this shop machines large composite structures efficiently.

-

Get Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

-

Finding The Right Words And The Right Process

This greeting card giant leverages hand-engraving competencies, digital media and high speed machining to produce press-ready dies so its cards are ready for the consumer's viewing pleasure.

-

Achieving Lean Success - A Holistic Approach

In order to understand the opportunities for extending the lean philosophy across the entire enterprise, it is important to understand the guiding principles of lean and the elements that comprise a truly lean initiative. At its most basic, lean is a focus on greater operational efficiency, the elimination of waste throughout the organization, and continuous improvement.

-

From Solid Models To Solid Machining Performance

Efficient model importing and toolpath generation help this shop deliver accurate parts more quickly.

-

Follow Your Blisk

Here are some considerations for successful blisk machining.

-

Where New Machines And Methods Overshadow The Old

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

-

Feature-Based CAM Helps Produce Self-Guided Vehicle

In constructing an entry for a competition of self-guided vehicles, electronic systems developer DesignJug LLC’s (Atlanta, Georgia) Team Juggernaut had to machine complex parts in aluminum, steel and even wood. The challenge was that the team, which consisted of a diverse group of inventors, researchers, design engineers and students, had minimal experience as machinists.

-

The Mold Consultant

This mold maker saves customers time and money by getting involved early in the design of molded parts.

-

CAM Software For Probing

Software for creating probing routines off-line promises to make machine tool probing easier to use. As a few examples show, different software providers look at this off-line programming in different ways.

-

Machining Center Trends Have Implications For CAM

At a recent presentation where he described some developments in his company's CAM software, Delcam product manager Mark Forth spoke of two clear trends in the way machining centers are being used today. For one, high technology is moving into a broader range of applications.

-

Tools For Profile And 3D Milling

Different tool shapes have different applications. Here is a look at form and function.

-

CAD/CAM Software Helps Mold Maker Survive And Thrive

Mold making has always been a tough, competitive business.

-

Getting To Know Knowledge-Based Machining

The term refers to different levels of automation that CAM software developers are building into their NC programming software.

-

Moving Toward Complete, Automated CAD/CAM Solutions

Best known for its machining software, UK-based Delcam is adding more software products for design and engineering. The company's explicit goal is to be 'a provider of complete, automated CAD/CAM solutions, taking complex shapes from concept to reality.

-

Software And Five-Axis Machining Center Provide Speed And Efficiency

Mold maker A.F. Gaskin (Buckinghamshire, United Kingdom) has customers who operate in fiercely competitive international markets, including Formula 1, and measure performance on the ability to deliver quality products in the shortest possible time.

-

The Right Start For A Fine Finish

Developers of CAM software have introduced many programming features for the initial removal of excess stock prior to finishing operations. By preparing the workpiece surface for more effective finishing, these roughing routines often determine how efficiently a CNC machining center can perform.

-

Pushbutton Die Making

High speed milling let this automotive forging company reverse a decades-old practice and bring die making back in house.

-

Software Speeds Up Automotive Part Inspection

Lotus Cars is known worldwide for creating award-winning sports cars at the forefront of vehicle design technology. The company has also developed a reputation for exceptional quality.

-

For World's Biggest Statue, CAD/CAM Plays A Crucial Role

The line of CAD/CAM products offered by Delcam (Windsor, Ontario) will play a crucial role in the production of a 500-foot statue of religious figure Maitreya in Bodh Gaya, India. The ambitious, international-scale undertaking is called the Maitreya Project. The hope and goal of this project is for the completed statue to serve as a destination for pilgrims and tourists from around the world.

-

Making Sense Of Model Data

Designs often arrive incomplete downstream. There may be no changing that. But these tools can reduce the amount of time spent on reworking customer models.

-

In Capable Hands

Putting NC programming and faster machine tools in the hands of machinists has helped this leading mold shop cut weeks out of the tool building cycle.