CAM Software Helps Reduce Machining Time By 80 Percent

This company upgraded its CNC milling capability and CAM software to make use of solid models and get its components produced more quickly.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreBy implementing feature-based CAM software from Delcam and investing in CNC mills, Hawk Industries, Inc. was able to reduce machining time for its alloy steel components by 80 percent and part programming time by 30 percent.

The designer and builder of specialty drilling tools for the oil and gas industry is based in Signal Hill, California. Hawk equipment—similar in function to an oversized pipe wrench—is used to grab the pipe as it is pulled out of the well and break the threaded joint or to create the joint as the pipe is placed in the well, torquing the joint to 40,000 to 80,000 psi. One part of the device holds the pipe, while another spins the adjoining segment to accomplish the task. These Hawk devices can undo a joint in about 8 seconds. They can save as much as 2 hours per day. On a rig that costs $150,000 to $300,000 a day to operate, that amounts to big savings.

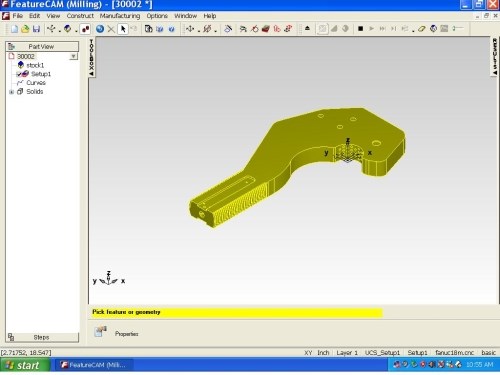

Determined to be competitive not only in quality but also in manufacturing methods, the company upgraded its CNC milling capability with the purchase of three mills and FeatureCAM software to take models of its components from SolidWorks to production quickly.

Mike Russo, manufacturing consultant at Hawk, had transitioned from simple 2D software to 3D software. In his own machining business, he had to be able to receive solid models from his customers and translate that into a CNC program, which was not a reasonable task with 2D software. This is when FeatureCAM came into play.

The impact the software has had on Hawk’s manufacturing capacity has been substantial. When Mr. Russo began working for Hawk, the company was shipping about 20 units per year. Today, with the help of FeatureCAM, the company is shipping 60 units or more per year.

At Hawk, more than 400 CNC programs have been completed in FeatureCAM. Typical machining tolerances in the 0.001-inch range are consistently achieved. According to the company, there has been a marked improvement in part consistency and a savings of more than 35 percent in assembly time for its complicated oilfield machinery components.

More than 500 different parts make up the devices. Most of the parts are 4000 series alloy steel and are heat treated after machining to extend durability.

“A big part of our effort to improve our manufacturing, including CAM, was to make our operation as automated as possible, reducing the amount of part handling,” Mr. Russo says.

On a spinner plate, the combination of FeatureCAM and CNC mills reduced processing time from 4 hours to 1.5 hours compared to the previous method. On another part, the machining (drilling, tapping and milling) and two-piece assembly time went from 3 hours to 35 minutes. In addition, the fit between the two parts has improved.

The new CAM package saves programming time as well as machining time at Hawk. Its feature-based programming makes it easy to create a CNC program for the company’s models. Most of the parts the company machines are held in custom fixtures, designed with FeatureCAM, to match the parts it must machine. This not only maintains consistency in setup, but also reduces setup time and allows the company to machine several parts in one setup.

With feature-based machining, the part is created using features that describe that part, from simple holes to complex pockets to turned grooves, and the operations are automatically generated.

Features are used as the building blocks to describe a complete part. They define shape, the faces of the part, the size and shape of pockets, slots, bosses, and grooves, the locations and types of holes, and whether those shapes have chamfered or rounded edges. Features can be revised rather easily by changing one or more individual parameters.

Part features not only describe shape, but also describe how to produce those shapes at the NC machine. They contain information describing how and where material removal should occur, cutting depths, whether to use climb cutting, whether to spot drill or center drill, and preferred machining strategies for roughing and finishing. When a part is constructed of features, the CNC programming process becomes automatic, the manufacturer says.

Hole features are commonly used, and Hawk says it makes a lot of holes for bolts, location and other purposes. First, the physical properties for the hole are defined, such as the hole diameter and depth, chamfer depth, counterbore diameter and depth, countersink diameter and angle, thread information and the coordinate location for each hole.

Then a drilling strategy is selected as well as whether to spot drill or perform a chip break. Based upon Mr. Russo’s choices, the software creates drilling operations. Defining holes in this way provides a single point of control as to how the hole is machined.

Once the operations are created, FeatureCAM selects tools based upon customizable rules. For example, if Mr. Russo specifies that a hole should be reamed, the program creates a drilling operation followed by a reaming operation. The drill chosen will be based upon a percentage of the final hole size, with the percentage being customizable.

Finally, once operations and tooling have been determined, the software recommends feeds and speeds. If Mr. Russo wants to change the recommendations for a specific application, he can override feeds and speeds as he creates the feature. Alternatively, he can edit the feed/speed database to adjust the feed/speed recommendations at the source, resulting in automatic recommendations that suit Hawk.

Mr. Russo can import a part design from SolidWorks into FeatureCAM and output a program in less than 10 minutes, including fixture design. Previously, it might have taken him 12 hours to program a SolidWorks model and additional time to try out the program. With the new program, Mr. Russo says he knows that the program will work without error or crashes. The manufacturing turnaround at Hawk seems to indicate that he is right.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)