Getting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

Share

A big machine tool gives the shop that owns it more flexibility than a small machine does.

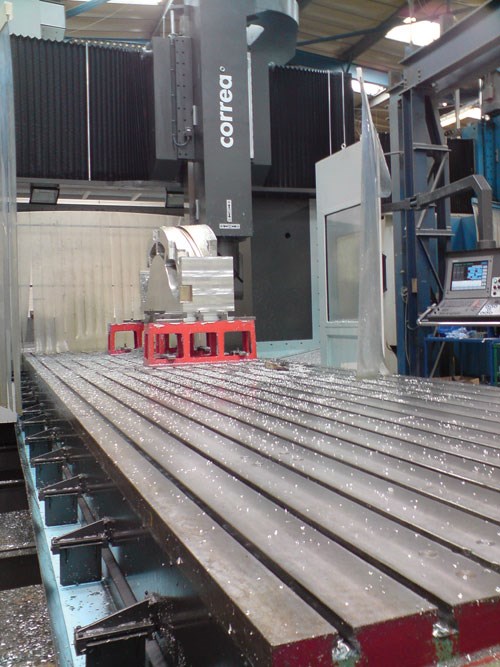

That statement may be a broad generalization, but it has proven to be a winning philosophy at Eccles Tooling Systems in Halesowen, West Midlands, UK. Managing director Bob Morton puts it plainly: “You can run a small part on a big machine, but you can’t run a big part on a small machine.” Thus, the larger machine affords more options. In pursuit of this flexibility, the shop has tended to buy the largest machines it can reasonably afford. The latest is the largest for this shop—a Nicolas Correa five-axis machining center with 8 meters of X-axis travel. By favoring “big” in this way, the tool and die shop actually won even more options than it anticipated, once its main source of business dropped away.

Michigan is not the only place where machine shops have lost business because of declines in the automotive industry. Michigan shops have brothers in this area of the UK. Ninety-eight percent of Eccles’s business used to come from the automotive sector, but now, no more than half of it does. Even so, the shop continues to thrive. The lost business was made up by aerospace work, which the shop managed to get—in part—because it happened to have the capacity to accommodate parts that were bigger than those it was accustomed to running.

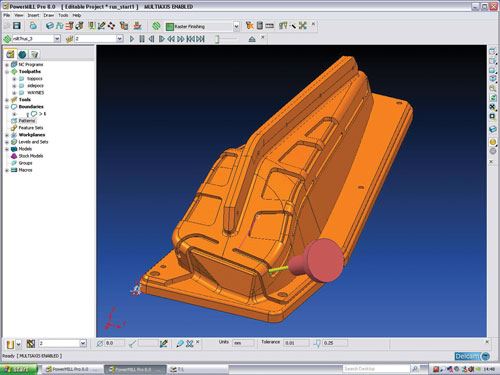

The shop now makes jigs and fixtures for aircraft manufacturing, including layup tools used to manufacture composite sections. (An example of such a layup tool is shown in the photos.) Much of the skill appropriate to die/mold machining is also appropriate to this work, so the transition was natural. The shop’s hardware and software were also appropriate. Like the shop’s Nicolas Correa machines, its PowerMill and PowerInspect software (from Delcam) are equally as capable for five-axis aerospace machining work as they are for the company’s molds and patterns.

However, Eccles owes more than open capacity and capable equipment for its ability to transition into aerospace work. In addition to pushing the size of its work envelope, the shop had also pushed its way into other capabilities and disciplines that ultimately made it well-prepared to serve this different market. According to Mr. Morton and project-and-works manager Neil Gerrard, these other important factors include:

• Shopfloor programming. For a die/mold shop, having seats of CAM software available on the shop floor can be an effective way to extend programming capability and prevent the engineering office from becoming a bottleneck. Operators on the shop floor can establish tool paths while programmers in the office focus on refining and proving the model geometry. However, with the large aerospace tooling work, shopfloor programming becomes even more important for ensuring the company uses its resources efficiently. These large parts occupy the machines for so long, it makes sense for employees on the shop floor to program the next part in the queue while the current part is running.

• Five-axis machining. Eccles has two machining centers with full five-axis machining capability, but its next machining center purchase will almost certainly have five-axis capability as well. The company has discovered five-axis machining to be effective even for parts that don’t necessarily have the complex swept surfaces that make five-axis machining essential. The reason has to do with undercuts, as well as the intricate, angled pockets that would require reorienting the part if the shop could not machine them with five axes. One recent job took 1 day to machine instead of the 5 days that Mr. Gerrard believes would have been required instead, thanks to all of the setups that five-axis machining allowed the shop to avoid.

• Mobile inspection. Inspection technology that can go to the machine tool is a convenience in cases when the part is still unfinished or the CMM is unavailable. However, this mobile inspection technology becomes essential when the part is too big for the CMM to accommodate. Eccles uses a portable Faro Technologies measuring arm to inspect the features of large parts. Rojac (see companion article above) uses a laser tracker from Automated Precision Inc. Measurement in general becomes more important in the move from automotive to aerospace work because the latter industry imposes greater demands on process validation and part traceability.

In a way, smaller parts now represent the more challenging work for Eccles. Not all of the shop’s parts use so much of the horizontal or vertical travels of its machining centers. In keeping with the shop’s philosophy, there are still plenty of smaller parts that the big machines run, too. But the large machines provide the flexibility to run these parts as if they were big, letting the shop set up more than one component or part number on the machine at the same time.

For example, the right- and left-hand components of a tooling set could be set up simultaneously and machined as if they were one piece, with cutting tools moving from one part to the other to machine similar surfaces and features. The Delcam software includes functionality for programming jobs in this way.

The challenge, says Mr. Morton, is for employees to think this way, and to take advantage of the machine capacity in this way. “One workpiece per cycle” is the natural way to look at CNC machining work. In a shop that makes the very best use of its big machines, though, multiple workpieces can fill out a single, shared cycle. That means the shop with big machines should consider whether any workpiece has the potential to figure into a “grouped” machining cycle that is greater than the sum of its parts.

Related Content

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreRead Next

Big Inspection With Little Difficulty

A portable laser tracker let this shop increase not only its machining range, but also the range of its services to customers.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More