Adaptive Machining Makes a Robot More Productive

This system for machining and polishing turbine blades shows the value of software for inspection, toolpath calculations and adaptive machining working together.

Share

The recent Paris Air Show not only showed examples of the latest aircraft, but also examples of the latest manufacturing processes for aircraft production. Perhaps less glamorous than, let’s say, the newest commercial airliner, exhibits of manufacturing technology were an important attraction for the thousands of aviation engineers and manufacturing executives who visited the huge show at Le Bourget Airport on the northern outskirts of the Paris metropolitan area, June 15-21.

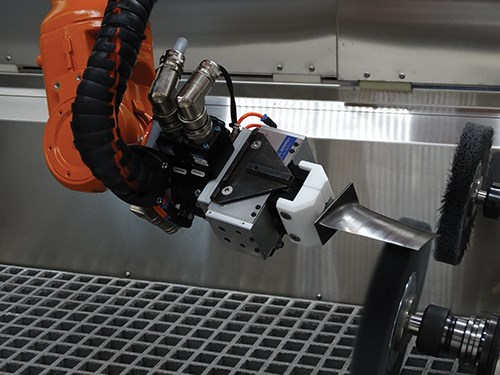

Among the exhibits was an automated system for machining and polishing jet engine turbine blades. This system consists of a Flexmill S Series platform in which an overhead ABB robot manipulates a turbine blade for probing, machining and polishing in one continuous process—fully automated, of course.

Click here to see a video of the process in action on Delcam's YouTube channel.

The dexterity of the robot is one essential capability of the system. It demonstrates how a robot, quite literally, picks up where a multi-axis CNC machining center becomes unhandy. However, the remarkable coordination of the robot and other onboard systems for measurement and metal removal obscures the underlying coordination of the software that enables the system to function so well.

This coordination represents a striking example of adaptive machining, where inspection is introduced into the process and is used to alter that process for each part individually in order to produce ideal results every time. In this case, all of the steps are fulfilled by software programs from CAM software developer Delcam. These programs work together seamlessly for design, machining and inspection. The concept and capabilities they embody are applicable to other machining and inspection situations as standalone products. The blade machining system simply provides a compelling context for examining

this interaction.

The Hardware Platform

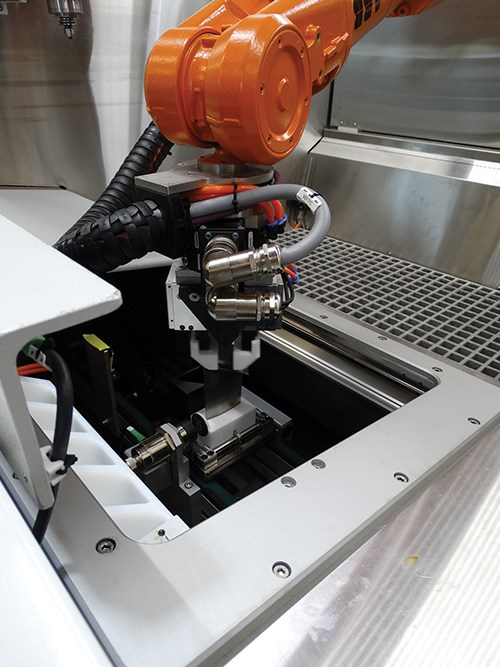

Flexmill, an offshoot of Finland-based JOT Automation, is a supplier of modular robotic solutions for manufacturing companies, especially those in the electronics industry. The company’s S Series platform is specially designed for robot-based milling, grinding, linishing (surface smoothing) and polishing processes. Depending on the application, various models of articulated (jointed-arm) robots from major robot developers can convey a part to processing stations within the machine or bring powered tools to a stationary part clamped in a workholding fixture.

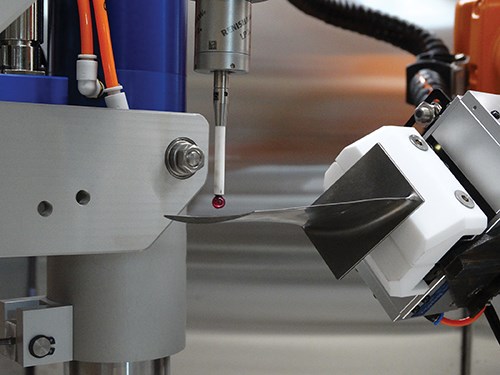

The blade processing system shown at the air show is equipped with an ABB six-axis robot mounted to the overhead frame of the machine’s structure. This configuration frees the space below for a variety of processing stations. In this case, two abrasive brush wheels rotating in separate, side-by-side spindles are located on the right of the workzone. On the left is a wall bracket that holds a touch-trigger probe on one level and a high-speed air spindle for a milling cutter on another level. All of the programmable axes required for processing the blades are part of the robot.

The space between these stations gives the robot plenty of room to maneuver the end-of-arm gripper holding a turbine blade. The blades used in this demonstration were roughly the size of a cake knife: about 6 or 7 inches long and about 3 to 5 inches wide. The system can also handle larger or smaller blades.

A workpiece shuttle transports pallets in and out of the enclosure from below the workzone. Each pallet has separate pockets for a finished and an unfinished blade. A roll-up cover in the floor of the machine’s base opens and closes above the shuttle station within the machine so that the robot can exchange the finished and unfinished blades. When a pallet is shuttled to the station outside the enclosure, the blades can be loaded and unloaded manually (although this step can be readily automated as well).

This Flexmill configuration takes up about 30 square feet of floor space, but larger systems can be configured to meet requirements.

Complementary Software

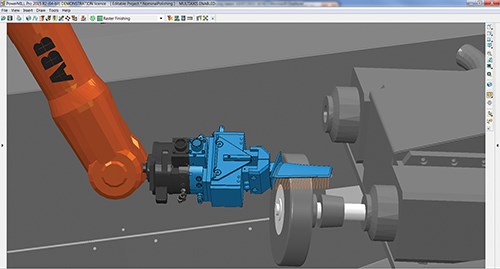

Delcam, which provided the adaptive machining technology and all underlying software for process automation, deployed three main software components for this application. PowerMill Robot performed the programming of the robot. Essentially, this software generates tool paths using traditional PowerMill capability, but provides an additional range of capabilities specific to robot needs in order to ensure accurate

robotic motion.

Unlike a machining center that has highly predictable moves for its available linear and rotating axes, a robot has many options for the way its joints move to create the desired motion. However, not all of these options are equally workable. Certain combinations of joint positions can create “singularities” in which the alignment of the joints restricts maneuverability or results in erratic motions. This situation is not unlike twisting an arm unnaturally to reach between one’s shoulder blades.

For this reason, PowerMill’s Robot interface includes simulation that shows the effects of the programmer’s directional choices for the robot so that singularities can be detected and corrected. After the robot program is proven in simulation, it can be postprocessed to suit the requirements of the particular model of robot in the cell. For this application, robotic programming includes routines to retrieve a blade, follow patterns that bring the curved surfaces of the blade in contact with the abrasive wheel, move the blade tip across a milling tool for trimming and return the finished blade to the shuttle.

The probing routines that work in conjunction with the machining operations are handled by PowerInspect, Delcam’s comprehensive inspection software. This software prepares the inspection sequences that enable the robot to touch the blade against the probe at the points necessary for the system to determine existing stock material on the blade. This step also checks the location and orientation of the blade. Machining paths are adjusted automatically to compensate for any misalignment that is found.

Adapting an Adaptive Process

The third software component is the automation that Delcam can bring, which bridges the probing and machining routines to create a true adaptive machining process. Essentially, adaptive machining uses in-process inspection to determine the shape of the part to be a machined, then adapts the tool paths to machine the part with high accuracy. This cycle can be repeated until there is complete compliance between the nominal part shape in the CAD file and the as-machined shape of the part.

Unlike the PowerMill and PowerInspect software, Delcam Automation is cloud-based process control software provided by Delcam Professional Services, a team of manufacturing software experts that creates a customized workflow for an application. For example, in this application, in-process inspection data is collected and used to reshape a nominal CAD model so that it represents the as-machined part. This new model is then used to automatically generate a unique set of tool paths for remachining. Once this workflow is established for the application, the adaptive machining feedback loop is coordinated by a computer connected to the machine control and linked to a cloud-based processing site, either on a shop’s network or on the Internet. The Delcam Automation system manages all of the process control for the fully automated cell, as well as the complex computing tasks, and provides the cell with the control commands required to keep production flowing.

Typically, blades processed on the cell make one or two passes across the grinding and milling stations. The abrasive wheel removes approximately 20 microns in a polishing cycle that lasts 30 seconds per side. Milling the tip edge using a carbide side-cutting milling cutter that runs at 8,000 rpm removes about 0.25 mm from the tip.

The Case for Adaptive Machining

According to Charles Jones, the industry marketing manager focused on robotic solutions at Delcam, a robotic system with adaptive machining is most advantageous when it can eliminate blending issues, avoid hand-finishing operations and minimize air-cutting time. In this case, it provides an efficient and economical way to produce smooth surfaces that are accurately shaped. Adaptive machining also leverages the flexibility of the robot. For example, compliant end-of-arm tooling can handle a variety of blade sizes because probing provides positive part location and orientation. There is no need for customized workholding fixtures.

Likewise, change-over is simply a matter of identifying the correct part number and calling up the corresponding CAD data and associated tool paths. Regenerating the tool paths for areas to be remachined compensates for inherent limits to rigidity of a jointed-arm robot. Finally, adaptive machining ensures that the finished part meets specifications for surface finish and dimensional tolerances. In this system, the robot isn’t finished until a good part has been produced.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)