Premier Prototyping Machine Shop Thrives on Software

Front-office automation and a discerning approach to work-free time for skilled CAM programmers to do what they do best.

Share

It takes a special kind of person to figure out everyone else’s problems. In the world of CNC machining, that is exactly is what Brian Kippen, CEO of KAD, has dedicated his business to: prototyping machined parts for some of the biggest companies in the world. For Kippen, the time spent prototyping is not a burden, it is his passion — one that has enabled KAD to grow to two locations to better serve his customers around the country.

Brian Kippen, CEO and founder of KAD, has spent his career programming parts and running CNCs. The company has locations in San Francisco and Vermont. The shop maintains rapid turnaround times for prototype parts through a highly optimized quote and CAM process. Photo credit: David Lyell

Specifically, the shop differentiates itself on work that requires not only rapid turnaround, but also making production quality parts without spending weeks refining the manufacturing process. Many of the companies that leverage the shop’s agility produce their own parts in-house but need additional capacity on short notice or don’t have the capacity to take on a small part run. As Kippen puts it, the goal is “to do it once and do it right.” For Kippen and his team, this works because passion for prototyping goes hand-in-hand with passion for programming. “We didn’t build the company as machinists, we built it as programmers,” he says.

Programming is at the heart of what KAD does as a prototyping shop. Every machinist has a dedicated computer workstation with large monitor so that they work quickly and comfortably. Photo credit: David Lyell

Granted, the path to premier prototyping bureau was not paved by passion alone. During a recent interview, Kippen provided insight into not only the mindset, but also the software tools and strategies behind the shop’s success. Three of the most important of these relate to quick quoting, an emphasis on programming and taking care in the selection of jobs. Here is more on each of these points:

1. Up-Front Automation

Kippen got his start in the machining industry while living in the San Francisco Bay area where he started working at a job shop as a machine operator in 2009. It was not long before his interests broadened, and he started to learn the programming side of the business. Kippen would stay late and work between jobs to refine his CAM skills and machining experience. Just a couple of years passed before he and a business partner, who was bought out in 2014, started KAD Models in 2011.

As the lead programmer for the shop, Kippen uses Surfcam to program parts. As an avid user for more than 10 years, the speed with which he works is invaluable. The rest of the shop uses Fusion360 to program parts. Photo credit: David Lyell

When the shop was getting its start on the west coast, it sought to maintain a rhythm of sending out part quotes within 3-5 hours. The shop strives to maintain that pace today and it has since become a hallmark of KAD’s service, Kippen says, both in San Francisco and the newer facility in Vermont. The shop’s ability to quote quickly relies on quoting software from Paperless Parts. Inside this software, the shop is provided with automatic, up-front analysis of designs that customers submit directly through the company’s website for information on pricing and manufacturability issues, such as parts that are impossible to mill or mating components that do not actually mate. In fact, Kippen credits the software for saving approximately 75 hours per month in administrative work — savings that are further magnified by additional revenue from producing additional parts on the shop floor.

2. Setting Up Shop for CAM

All of the machinists collaborate throughout the process of quoting a part to its manufacture. Kippen has leveraged the shop’s proximity to Vermont Technical College by tapping into the pool of students that have experience working in the Advanced Manufacturing Department. Photo credit: David Lyell

The Vermont facility’s office area still reflects its heritage as a tractor repair shop, with various hooks and markings along the walls where engine belts were kept in stock and stout workbenches that were made for repair work. However, the first thing one would notice when walking in the front door is the bank of workstations for the machinists. Reflecting the shop’s emphasis on programming, each is equipped with high-quality tools for the job — namely, a powerful desktop computer and a large monitor. To facilitate the necessary concentration for this work, Kippen is also adamant that programming should happen in the office and off the shop floor as much as possible.

As for software tools, KAD has options. Kippen prefers to program parts in Hexagon’s Surfcam, citing the speed with which he can work after using the software for over 10 years. However, the rest of the team uses Autodesk’s Fusion360 to program parts and routinely leverage the robust simulation feature built into the program — a feature that Kippen leans on infrequently.

3. A Discerning Approach

Perhaps the most routinely challenging aspect of programming for CAM is interpreting dimensions, Kippen says. With the diversity of projects that come through the shop, the number of dimensioning systems, and “alphabet soup” as Kippen calls it, leads to slow programming as the machinist interprets different systems and techniques for call outs that other shops implement. Frequently, the shop will run into tolerances that are impossible to keep because of the design of the part or that do not account for other requirements, like plating.

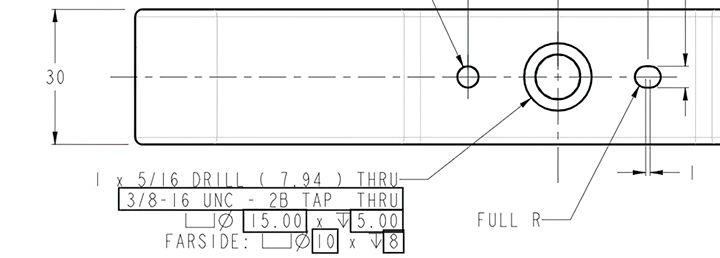

Kippen has noticed a tendency for novice engineers to create impossible designs, whether it be a hole that is tapped through an impossible amount of material or counterbores that are deeper than the part is thick. Material thickness of this part is 12 mm. Counterbores of 5.00 and 8.00 mm will exceed part thickness.

Photo Credit: KAD Models Inc.

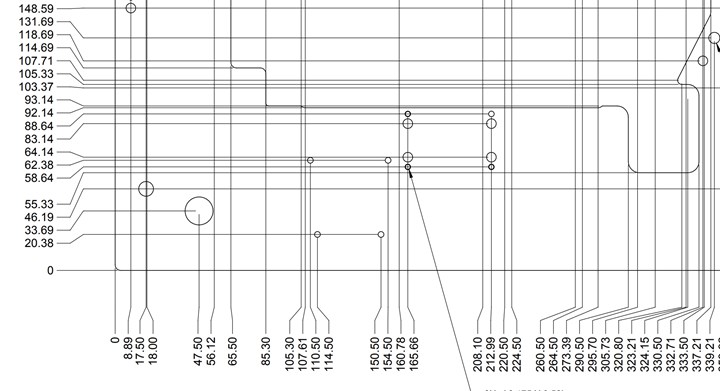

Leaving time to work through such problems requires a discerning approach. For example, the team is wary of 2D drawings not only because they must be translated to 3D models for CAM programmers, but also because that work can be more time- and cost-intensive than it initially appears. In many cases, these drawings are very complex, or they lack sufficient information to build a solid model. In these situations, it can be best not to quote the job. As is the case with the quoting software, the net effect of such an approach is to free time for doing what the KAD team does best: programming parts.

Over-dimensioning a part can complicate CAM programming. While 2D drawings are helpful for things like understanding tolerances in assemblies, on their own they can complicated the translation into CAM.

Photo Credit: KAD Models Inc.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

If You Prototype It, They Will Come

For an upcoming article, I recently visited Protofab in Petaluma, California. I wanted to learn how this small job shop got into micro-machining medical implants. It turns out the shop didn’t win this work because it had the right equipment or because it was knowledgeable about machining tiny parts. The equipment a

Read MoreWhen It Comes to RFQ Response, Time Is Money

But in this case, the more time it takes, the less money you’re likely to make.

Read MoreWhen Too Many Customers Spoil the Part

Duo CNC used to take on as many customers as the shop could handle. But when growth stalled, a top-down audit by the company’s general manager revealed that its customer base was inhibiting growth — and causing the shop to be less efficient and productive.

Read More