Autodesk Introduces PowerMill 2019 and Fusion Production at Its Smart Manufacturing Celebration Event

Autodesk’s Smart Manufacturing Celebration showcased enhancements to PowerMIll 2019, the latest release of its flagship CAM programming systems, and demonstrated the integration of production scheduling, job tracking and machine monitoring.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk chose an especially appropriate setting for its Smart Manufacturing Celebration in late April. The company hosted the event at the newly expanded facility of Paragon D & E in Grand Rapids, Michigan. Paragon is a diversified manufacturer that specializes in advanced die and mold production, aerospace components and other challenging machining applications. About nine years ago, Paragon decided to select one CAM supplier to use exclusively for its NC programming requirements. At the time, its programmers were using a multiplicity of CAM software products, a situation that made consistent machining results and smooth workflow difficult to achieve. In an effort to standardize, the manufacturer chose PowerMill by Delcam (acquired by Autodesk in 2014) largely because the software’s simulation features helped the shop avoid programming errors that had been causing costly damage to expensive machining assets, particularly a large double-gantry machine that had been installed to produce complex components in five axes. PowerMill was not new to Paragon at the time—the company had been using it for years, along with other programming systems.

After making the decision to standardize on PowerMill, Paragon President David Muir says the relationship that emerged between his shop and the CAM developer became less passive and more of a partnership in which Paragon can be both a test bed and an originator of new ideas in NC programming.

In fact, Paragon is one of the first end users to implement the two Autodesk products highlighted at this two-day event, which included technical presentations, product demos, plant tours and hospitality functions. For example, Autodesk used the occasion to launch PowerMill 2019, certain features of which are said to reflect input from key users such as Paragon. Noteworthy enhancements in this release include the following:

Five-axis collision avoidance. A new “automatic tool-axis tilting” method helps generate smooth and safe five-axis motion. Regardless of part geometry or tool path type, the intent is to make creating five-axis programs as easy as creating three-axis programs.

High-efficiency roughing. Vortex, PowerMill’s roughing algorithm that maintains a constant axial angle of cutter engagement for a consistent, optimal chip load, now has a “from stock” option based on the company’s Adaptive Clearing technology. This option creates tool paths with offsets based on both the desired shape of the part and the actual stock being milled. By avoiding excess trochoidal moves and tool retractions, roughing operations are faster and leave more even stock conditions for efficient finishing passes, the company says.

Programming aids for additive/subtractive hybrid machines. PowerMill 2019 has a suite of additive programming functions supported by simulation capability. These software functions are designed to generate tool paths to drive machine motions that enable wire-fed or powder-blown hardware to build up features while the workpiece is mounted in the machine. The software can also be used to build up entire components from scratch.

A direct interface for shopfloor integration. PowerMill data such as NC programs, setup sheets and work instructions now can be shared among shopfloor, front office and programming department personnel with Fusion Production.

This interface with Fusion Production is especially significant because this is Autodesk’s offering in the “smart manufacturing” arena. Introduced at this event, Fusion Production is a cloud-based system that combines scheduling, production tracking and machine monitoring on one platform. By virtue of the interface with PowerMill, users can access shopfloor CAM data on internet-enabled devices such as mobile phones and tablets. However, considerable attention was given to other prominent features of Production Fusion.

Although machine-monitoring systems have been installed in numerous machining companies, many of these companies have had difficulty sharing data with existing scheduling and production-tracking systems and other shopfloor control applications. With Production Fusion, this integration is built in, Autodesk says.

Paragon is in the process of implementing this platform. A shopfloor demonstration showed how detailed reports from connected machines conveyed utilization rates, fault and alert histories, part counts and other operator-entered information such as reasons for downtime. These reports can be viewed in typical dashboard fashion. This demonstration was impressive because it clearly reflected Autodesk’s grasp of the importance of machine-tool connectivity. This may contrast with other Industrial Internet of Things (IIoT) or Industry 4.0 platforms that offer limited or underdeveloped provisions to deal with the multiplicity of CNC types and legacy machines that are the reality in most machine shops. Notably, Production Fusion takes advantage of interoperability standards such as MTConnect for shopfloor networking.

The demonstration also gave convincing evidence that the theme of partnership between Autodesk and Paragon was mutually beneficial. Both companies seemed intent on learning from one another, as they have for many years now.

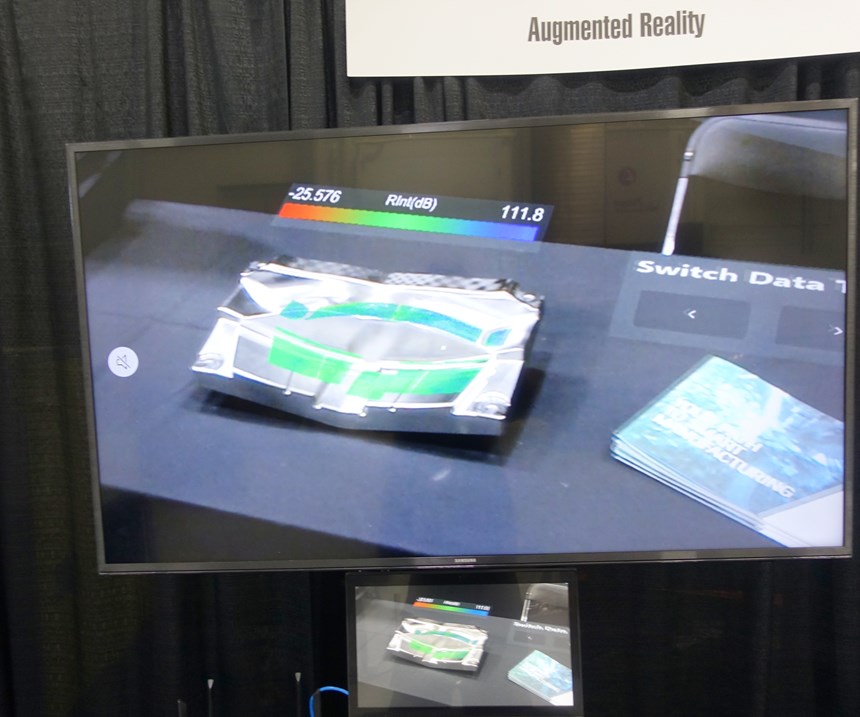

Whereas the first day of this event was focused on Autodesk’s role in advancing smart manufacturing with its products in general and for Paragon in particular, the second day focused on a broader discussion of digital manufacturing. The theme of partnership carried over to many of the presentations on this day, showing how leaders in digital-manufacturing concepts are bringing tangible benefits to the real world and to users. For example, Todd Sunderquist, chief program engineer at Ford Performance, spoke about how digital developments in the design and construction of a successful Le Mans-class racecar were improving production vehicles for better performance and fuel economy. Likewise, Matthias Dannapfel, chief engineer at Aachen University in Germany, discussed how augmented reality could customize training or instruction to suit the level of experience of shopfloor personnel, thus making manufacturing jobs more gainful to both employee and employer. Kevin McDunn, chief technology officer at the University + Industry Labs’ Digital Manufacturing and Design Innovation Institute (DMDII), discussed how a realistic vision for smart manufacturing in the United States could be summarized as leveraging new digital technology “to make every part better than the last.” He presented case histories showing the results of this grassroots effort in action.

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)