For Straitline Components in Sidney, British Columbia, the difference between downhill and cross-country mountain bike racing was the difference between milling and turning. Introducing a new bike stem for cross-country riding required this small shop and bike component maker to invest in a nine-axis multitasking turning center with two workpiece spindles and the capability for five-axis milling. Company co-owner D.J. Paulson says a major part of the investment has been the learning curve he has gone through to become proficient with the machine and apply it effectively to Straitline’s new part.

It was worth it, he says. While Straitline certainly could have machined the part using its existing equipment—turning it on a CNC lathe and milling it on a machining center—producing it this way would have meant making and using specialty fixtures, which would add setup time and also add to the danger of setup-related error.

More crucially, co-owner Dennis Paulson says, “We would also have had to make fixtures just to prototype the part.”

The problem in this last point is that the part’s design is still being refined, even today. It is being improved for functionality, economy and manufacturability. While the new turning center is complex, that very complexity enables the machine to deliver simple processes. Because it permits single-setup processing with no need for special fixtures, the machine makes it possible to keep improving the part’s design well into production.

Two Companies in One

Modern Machine Shop first covered Straitline Components in September 2011. The company also makes parts under the name Straitline Precision Industries. While Straitline Precision is a job shop making high-value parts for industries such as aircraft manufacturing, Straitline Components is the brand name by which this shop makes and markets bike parts. This latter business came about because of the team’s own interest in mountain biking.

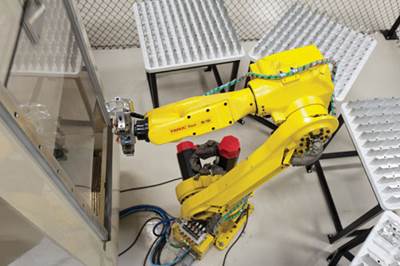

That team is tiny. Rarely do more than three employees staff this shop’s production floor at any time. To make the best possible use of minimal manpower, the shop invests in automation—and in fact, boldly invests in it. Our

previous article described Straitline’s use of a palletized HMC and a robot-loaded VMC. Both machines continue to run unattended, making parts for hours on end during most workdays. The multitasking machine is the latest piece of equipment that will be expected to run several cycles in sequence. One 6-foot length of barstock on this machine is enough to produce 16 of the cross-country stems before a staff member has to load another bar.

The new stem is Straitline’s “Amp” design. The stem is the part of a bike that connects the handlebars to the steering tube. A longer stem holds the handlebars farther forward on the bike, giving the rider more room to lean forward. On downhill or freeride biking, a shorter stem is better because it lets the rider lean back. For cross-country riding, a stem like the Amp can let the rider lean forward for power while pedaling up hills.

One of the photos shows the Amp stem’s primary machined part alongside the same part from an earlier stem design. As the comparison shows, the shorter stem can be processed exclusively on a machining center. The Amp stem, with its cylindrical shank, is a turned part.

Getting Up to Speed

The turning center Straitline chose is a

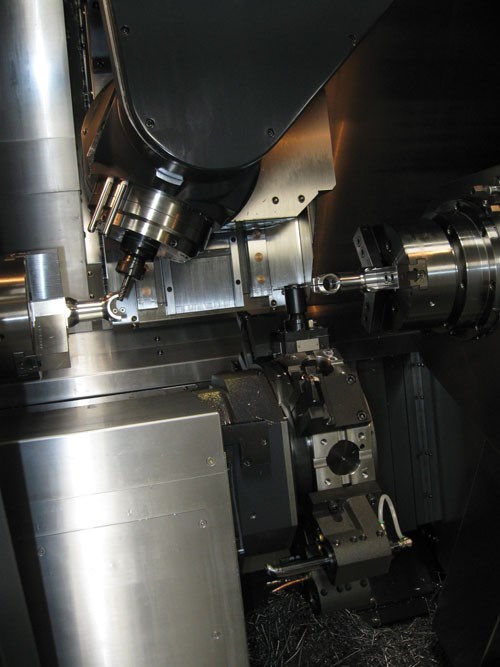

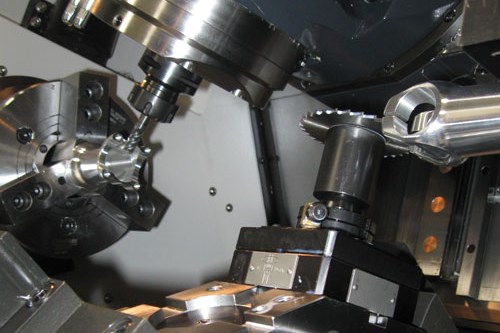

Doosan MX2100ST. The machine fit Straitline’s requirements in various ways. For one, it can feed 2-inch square barstock. Machining the 7075 aluminum stems out of square bars instead of round bars saves material. Also, machining parts in two opposing spindles at once reduces cycle time. The Doosan machine features a lower turret that performs turning and milling, while a separate milling spindle pivots to perform angled or contoured milling. Both the turret and the spindle can machine parts in either workpiece spindle. The B axis of the milling spindle plus the C axis at either of the workpiece spindles make possible five-axis machining.

D.J. Paulson took the lead in becoming proficient with the new machine. He says that using the machine as its owner (rather than as an employee) might actually have made learning it more difficult, because of the extra caution he exercised. Early on, out of the fear of some misprogrammed move crashing any two of the nine axes together, he thought carefully about every move and fed the machine slowly and carefully.

Lack of time proved to be his biggest challenge. Mastering the machine and engineering the process for making the stems probably should have required no more than six weeks. That includes getting accustomed to programming synchronized operations on the shop’s CAM software, Delcam FeatureCAM, as well as the time to test and refine the machine’s postprocessor. However, the shop got so busy that he wasn’t able to spend six weeks giving this machine his primary attention. Instead, a month and a half of attention got spread over five months. During all of that time, the new machine was underproducing because Straitline still hadn’t mastered it.

A customer part finally forced the issue. A contract job for an aircraft-industry customer involved a part with milled surfaces at various angles. Producing the complex part on the Doosan gave D.J. the chance to ascend higher up the learning curve, setting up Straitline to begin succeeding with its new machine.

Unfortunately, other aspects of the learning curve had nothing to do with the machine or software, but instead had to do with the challenges of the new stem part.

ID Gripping

The machining operations on the second spindle were the area of difficulty, D.J. says. The stem is not just a hardware connector, but also part of the appearance of the bike, and a rider is likely to choose a stem largely for its aesthetic appeal. Straitline’s process involved machining the part’s finished OD surface in the first spindle. Subsequently clamping the OD in the second spindle might distort the part and would almost certainly mar the attractive surface.

But clamping from the inside did not prove rigid enough, D.J. says. One problem was the part’s slight conical ID taper, which required chuck fingers to have the same conical profile. Another was the tendency of the chuck fingers to deflect. This led him to create preloaded fingers that would deflect into alignment with the inner surface of the part. Even with these steps, the part kept slipping. “It was baffling,” he says.

Worst of all, the slip often was too subtle to produce a clear and obvious defect. Just a slight slip during machining would throw the handlebar bore and steering tube bar slightly out of perpendicularity—an error that still would have to be caught because it would affect the alignment of the handlebars.

The solution was discovered thousands of miles away, at the International Manufacturing Technology Show in Chicago this past September. On their final day at IMTS, the brothers were making a hurried trip through the Tooling & Workholding Pavilion when they found

Carbinite Metal Coatings, a company that adds tungsten alloy coatings to workholding components to improve their grip. Soon after he returned home, D.J. sent the ID grippers to Carbinite to receive this coating. As soon as the grippers returned and he re-installed them on the chuck—aligning them with the use of a sample stem part—it became clear that the coated surface would solve the problem. D.J. tried to turn the stem on the grippers by torquing it with a long-handle wrench, only to move the part, chuck and spindle all at once.

The brothers found another stem machining process improvement at IMTS as well. A boring tool from Criterion Machine Works that can be held in a collet chuck in the milling spindle is precisely the right size for the bore machined in the second spindle. Implementing this tool saved cycle time and improved accuracy by allowing the shop to get away from helical milling for this bore.

Opportunity

Now, Straitline has risen well beyond the steepest part of its learning curve with the new multitasking machine. The view from this position is spacious. Expected demand for the Amp stem is 6,000 pieces per year—a production volume that will pay for the turning center without filling it. The remaining capacity will open doors of opportunity, the brothers say, because Sidney is remote enough that there are not many other machines like this one to be found in shops anywhere close. Already, the shop is finding itself making use of the machine to quickly deliver what Dennis calls “small-lot, tight-tolerance, weird-angle jobs.”

And there are plenty of jobs out there like that, he says. In equipping the bike component side of its business, Straitline equipped the job shop side of its business to move forward as well.