Software Separates Shop From Competition

FeatureCAM’s feature-based programming capability and five-axis machining strategies help this shop set itself apart from the competition. In fact, the shop has increased gross sales by more than 30 percent in a few months after integrating FeatureCAM’s five-axis machining package.

Share

Autodesk, Inc.

Featured Content

View More

Shops like Padgett Machine (Tulsa, Oklahoma) are the backbone of the aircraft maintenance industry. Approximately 95 percent of the company’s work involves military aircraft, including parts for F-16s, B-52s and other famed fighters and bombers. Company president Ed Padgett says maintaining an edge in heavy maintenance programs for military aircraft is important in this competitive industry. "We have to be competitive with 10 to 15 other vendors every time we bid on a job, or I lose my business," he says.

One way the company sets itself apart from the competition is by working with FeatureCAM software from Delcam (Salt Lake City, Utah). The software’s time-saving features and efficiency across the range of CNC machines in the shop have helped Padgett increase profits since implementing FeatureCAM in 2002. The latter feature is especially important, Mr. Padgett says.

"I have seen some shops that have one CAM package for a turning machine, another for their mills, and on and on," he explains. "The cost for each different seat and the time to learn the different software are time and money wasted without any real benefit to the quality of parts produced or ability to turn jobs. Using FeatureCAM, we can modify a post-processor for any type of machine in minutes."

FeatureCAM incorporates a combination of feature- and knowledge-based functionality designed to make programming faster and easier. The software family offers a range of programs for milling, turning, wire EDM and turn-mill applications, all with the same interface style. The software’s automatic feature recognition technology divides part designs into specific features such as holes, slots, pockets and bosses. The software then automatically selects the most suitable tools; calculates feeds and speeds; generates tool paths; and produces NC code in a single, automated operation.

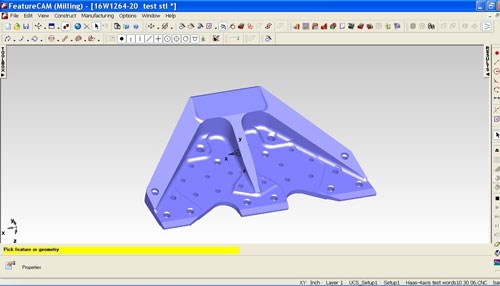

Feature-based machining has been extremely helpful to the shop in generating CNC programs. That’s because many of Padgett Machine’s parts start not with a CAD file, but with an old drawing—sometimes more than 50 years old. "It’s mind-boggling how they built more than 700 B-52 bombers in the 1950s manually, without the benefit of CNC," Mr. Padgett says. "The drawings don’t really reflect the complexity of the parts."

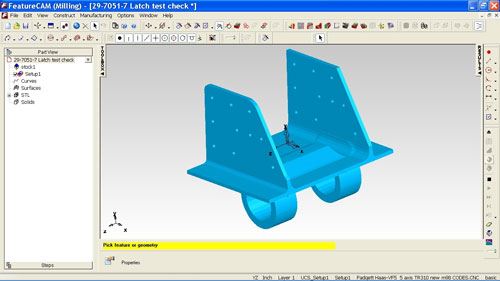

For such parts, Mr. Padgett inputs the dimensions from the drawings, a process that can take up to 15 hours. Writing a program manually would significantly increase this time commitment. However, the software’s feature-recognition technology enables Mr. Padgett to generate a solid model from the information he inputs into the interface’s dialogue boxes. The program is defined automatically, complete with rules for each feature describing information such as how and where material removal should occur, cutting depths, and machining strategies for roughing or finishing. This eliminates the time-wasting chore of creating and managing each machining operation.

"The process code for just one of the parts we are working on from the B-52 is 2,700 pages—we don’t even print it," Mr. Padgett says. "FeatureCAM processes the machining code in less than 20 seconds."

To revise features, the programmer simply changes one or more individual parameters, such as depth or radius, and the entire program updates automatically. Mr. Padgett says feature-based programming saves his shop at least 2 hours for a simple part program and 6 hours or more for complex programs.

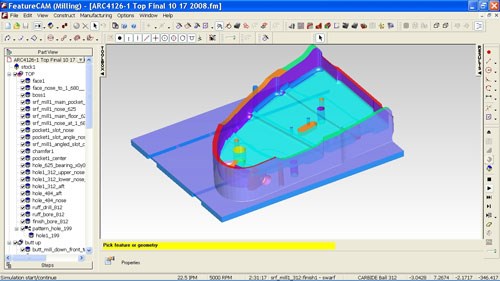

Another component of FeatureCAM that has helped Padgett Machine improve profit is the software’s support for five-axis programming. Recently, the shop invested in the software’s five-axis machining package along with a new five-axis machine from Haas. Mr. Padgett says adding this capability has helped the company increase gross sales by approximately 35 percent. "We are four months into this new line of five-axis programming and machining work, and we are already profitable with it," he says. "This would not have been possible without FeatureCAM’s support of five-axis positioning and five-axis simultaneous machining operations."

The five-axis machining package provides a number of methods for controlling tool orientation. For example, Mr. Padgett can set a specific lead and/or lean angle. The lead angle is measured in the cutting direction, while the lean angle is measured at right angles to the cutting direction. This is useful for either reaching areas that would be inaccessible with three-axis machining or for taking advantage of better cutting conditions. Alternatively, the tool angle can be set in an orientation either to or from a point, or to or from a line. This capability is said to save time and material when machining structural aircraft components.

Additionally, Mr. Padgett can convert three-axis tool paths generated in FeatureCAM to five-axis equivalents by using automatic collision avoidance to change the tool orientation when collisions might occur. The software automatically tilts the cutter away from the obstacle by the specified tolerance and then returns the cutting angle to the value set for the overall tool path once the obstacle has been cleared.

Another feature Mr. Padgett likes is the software’s swarfing command. He says that by selecting a surface for the tool to follow, he can cut programming time for airframe parts in half. The software’s five-axis trimming and swarf-machining techniques are particularly effective for machining pockets in aerospace structures, such as a wing rib for an MD-11 airliner. The shop had to build 60 versions of this part based on a wing surface model and drawings of the ribs with station locations from the airframe manufacturer. FeatureCAM proved to be invaluable for this operation, Mr. Padgett says.

"Using FeatureCAM’s five-axis capabilities allowed us to fixture the part so that we can machine the top and four sides in one setup, saving quite a bit of time and providing much better results," he explains. "With a three-axis machine, it would take eight or nine setups for some of these parts."

Mr. Padgett says other important software features include the spiral-path-milling strategy, which eliminates air moves by keeping the cutter in constant contact with the workpiece, as well as milling strategies that keep loads on the cutter as consistent as possible to prolong tool life. He also uses the software to help build quotes when he receives a solid model. "I can do a time study that will be accurate within 2 to 3 percent of what it will cost to produce a part, depending on material; add it to our MRP quoting system; and quickly provide an accurate quote in terms of time and cost to produce the order," he says.

Efficient and effective CAM programming has proven to be a key ingredient in the company’s success. The shop has already purchased nearby land in order to double the size of its facility.

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)