Mold Maker Cuts Delivery Times With CAD/CAM

Staying competitive in the automotive industry requires quick turnaround, a fact not lost on this manufacturer of foundry tooling. Upgrading to a CAD/CAM system from Delcam helped the shop significantly increase machining efficiency and reduce delivery times.

Share

Hitech Shapes & Designs, a division of Seilkop Industries in Cincinnati, Ohio, has been building foundry tooling since 1946. Since then, Hitech has kept up with new manufacturing technology, evolving from hand-crafted wood and metal patterns to CNC capability. Staying on the cutting edge is not just beneficial for the company, but essential—most of its customers work in the automotive industry and demand quick turnaround.

As part of its ongoing effort to stay competitive and meet delivery targets, the company invested in a CAD/CAM package from Delcam that reduced both programming and machining time by approximately 25 percent. In addition, the software was easy to learn, according to CAD operator Les Wright. “With only five half-day classes, I was up and going with it,” he says.

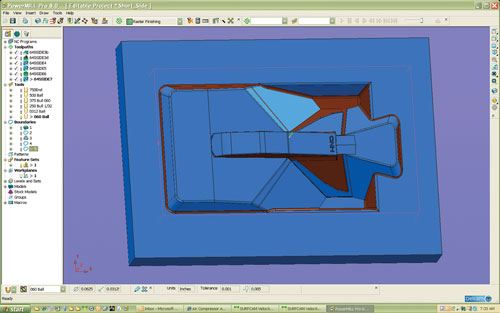

Hitech specializes in the design and prototyping of automatic molding tooling for casting. Frequently starting out with a raw chunk of material, the company uses its six three-axis mills and two CNC lathes to cut aluminum, iron, plastics, urethane, tool steel and even wood. It works closely with customer design teams to streamline production processes, and it helps anticipate changes required for the casting process through solid model transfer. The shop imports solid models from customers or creates them from paper drawings using PTC’s Pro/Engineer design software. After completing pattern tooling design, Mr. Wright uses Delcam software to create programs derived directly from customers’ solid model files.

PowerShape, Delcam’s CAD application, provides various strategies for constructing a surface from a given set of lines, arcs or points. Smart Surfacing capability enables the software to automatically choose the method that will provide the smoothest possible surface. Additionally, this feature automatically updates the software’s selection when information is added to the design. As additional points or lines are inserted into the model, PowerShape reviews the chosen surfacing method and regenerates the surface with an alternate solution if a better one exists.

Once the file is imported into the PowerMill CAM application, this makes it easy to program the machining in layers to suit the lengths of the company’s cutters, Mr. Wright says. “Programming in layers allows us to program the machining efficiently and avoid cutting air,” he adds. “This saves all kinds of time, which is important to our success.”

Mr. Wright says one important benefit of PowerMill is the software’s automatic corner finishing capability. This feature allows the use of larger cutters when possible before switching to smaller tools for corner finishing. In contrast, the company’s previous software often called for machining an entire part with a small cutter just to access a tight corner. Additionally, programmers often had to create splines around each small corner to clean it out. “PowerMill does that automatically,” Mr. Wright says. “The cutters machine only where they are needed to clean up corners. The result is a more correct pattern in less time.”

Compared with the previous software, this function alone has reduced both programming time and finish machining time by approximately 25 percent. Hitech says the software helps save time in another way as well—it enables the company to cut a pattern out of solid material rather than first working with a molded part made from a master pattern. To ensure safe machining, the software automatically checks for potential cutting tool collisions. Meanwhile, contact-point analysis ensures that only the cutting edges touch the pattern or prototype part.

Also, Mr. Wright says PowerMill is more efficient than the previous software when programming high speed tool paths. Most of the shop’s machines use 15,000-rpm spindles, and with a 1.25-inch cutter, operators can achieve feed rates as fast as 300 ipm. “The key is that it does not make any sharp turns, but arcs in and arcs out, which is easier on the machine and tooling when moving at high speeds and feeds,” Mr. Wright says.

Once a prototype casting is delivered and evaluated by the customer, its file can be changed and returned to Hitech. Mr. Wright can overlay the 3D model from the customer and see any changes in the new casting file he gets back. He can select the areas of a pattern that need cutting and modify the file so that the machine will concentrate only on the area of concern, saving time in reprogramming and machining.

The ability to go from a solid model to an accurate machining program has cut turnaround time in half. Deliveries that typically took 12 weeks with the previous software, for example, now might take as little as 8 weeks. In addition, the software’s machining strategies help avoid cutting air, so machine time is chip-making time. The result is that the entire pattern-making cycle is 25-percent faster than before. A pattern that used to take the company 12 hours to program and machine can now be completed in less than 8 hours.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;width=860)

.jpg;maxWidth=300;quality=90)