An Improved Method for Machining Blisks

A software designer and a tool maker collaborate on a system for machining blisks that focuses on the point of contact between the workpiece and the cutting tool.

Share

As blisks have transitioned primarily from use in military jet engines to commercial aerospace and industrial applications, global production has soared. This growth in recent years has spurred innovation in the manner in which blisks—a combination of “bladed” and “disk”—are manufactured, particularly in the areas of design software and specialized cutting tools, with shops searching for ways to machine them more quickly and at a lower cost.

Recognizing this trend toward higher production rates and the desire by more manufacturers to get involved in machining blisks, Delcam, part of the Autodesk family of companies, and Technicut, the largest cutting tool supplier in the UK, joined forces to mate software technology with advanced tooling for an innovative approach to manufacturing these critical rotating parts.

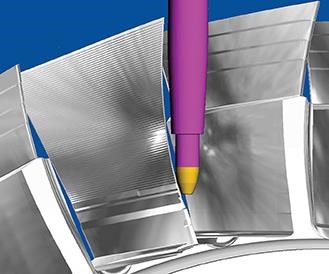

According to Ian Caldicott, senior consultant on the project at Delcam Professional Services, his company has collaborated with Technicut for more than a decade in cases in which custom tooling is required for a new software program he and his team have designed. Technicut’s business model involves designing custom tooling specifically for its customers’ applications, so when Delcam decided to self-fund R&D of a new approach to machining blisks, the toolmaker was the ideal partner. The project began with an examination of the interplay between the cutting tool and the blisk, generally made of titanium or nickel-based alloys such as Inconel. From there, the team began focusing outward from the workpiece, next studying the toolholder and then the spindle, examining the entire “kinetic chain” involved in the machining process. (A chain is only as strong as its weakest link, after all.)

Mr. Caldicott says Delcam’s PowerMill software was already capable of all the design, simulation and toolpath instructions the blisk milling process would require, but the software’s full potential for this particular application could only be reached with specialized tooling developed specifically for blisk milling.

One tool in particular was determined to be integral to the success of the project. Technicut’s Titan X-Treme ripper end mill, used for roughing and removing material from between the blades with a series of slotting cuts, is designed with a broader, flatter tip than traditional tooling so that more material can be removed in a single pass. This operation also relieves stresses in the billet that are sometimes introduced during the forging process. Technicut also designed special barrel cutters for semi-finishing and finishing that have a larger radius on the cutting surface than the ballnose cutters that are often used in machining blisks. This results in a stepdown that is three to four times broader than passes made with ballnose cutters, according to Delcam, delivering the necessary surface finish while reducing machining times significantly.

Paul Wilkinson, general manager of Delcam Professional Services, says tests performed on an 804-mm-diameter billet made of Ti6-4 titanium with 31 blades—each of them 84 mm in length with a root radius of 4 mm and a scallop height of 10 microns—revealed that cycle times had been cut in half, from 70 to 35 hours, and milling costs were reduced by 45 percent. Mr. Caldicott says planned future software developments include:

-

Dedicated blade blisk impeller strategies.

-

Continued improvements in smooth toolpath generation.

-

Advanced toolpath\tool-axis editing features for added flexibility.

He adds that this project is an example of Delcam’s approach to addressing a future in which manufacturing is smarter, more collaborative and accessible, and hyper-focused on process efficiency. By examining the cutting tool/workpiece interface before machining, the software could be massaged to maximize the potential of the cutting tool itself, making it cut faster and more effectively and last longer, and reducing the cost of machining.

Related Content

Rego-Fix Appoints New Global Aerospace Specialist

Sherman D’Souza will provide global customers with access to Rego-Fix research, development and technical support teams to create and supply toolholding solutions.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreThe Role of Surface Finishing in Modern Manufacturing: Trends and Best Practices

You’re attending IMTS to advance your business. Regardless of your role in the manufacturing process, considering how your parts will be finished is crucial. This article can help you understand trends in surface finishing and better communicate with your finishing partners.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More