Share

Generative design software is coming down to earth. There is a bit of irony in this assertion, because it is based on observations centered around a striking example of advanced, outer-space hardware—a conceptual model of an interplanetary lander. Fully developed, a lander of this type might someday explore one of our solar system’s most unusual objects, Europa, a distant moon orbiting Jupiter. Here on Earth, a prototype of this lander’s design concept represents several advances that are making generative design software increasingly significant to this generation of designers, engineers and manufacturers, according to developers at Autodesk involved in this project.

More than just a geometry modeling tool, generative design has become a manufacturing process selection tool as well, along with a tool for making best use of various manufacturing processes available. The latest generation of generative design technology includes new ways to set design boundaries and to constrain the algorithms to more quickly identify designs meeting predetermined manufacturability requirements, including requirements defining particular manufacturing processes. As a result, generative design is less and less a tool strictly associated with additive manufacturing, Autodesk says. Multi-axis machining might be the best choice, as it turns out, even for a very elaborate part, when certain constraints are in place.

But what is “generative design”? Generative design is a relatively new approach that uses machine intelligence (algorithms that solve problems the way the human mind does but much faster and more powerfully) and cloud computing to generate a broad set of design possibilities that fit within the performance requirements set by engineers. Autodesk says that, with its generative design technology, users can simultaneously generate and explore hundreds or even thousands of manufacturing-ready solutions based on product constraints and requirements such as strength, cost and materials. According to the company, manufacturers can leverage real-time performance data and smart manufacturing processes to accelerate the delivery of innovative new products to market.

Insights into new developments in generative design were some of the key take-aways from Autodesk University (AU), which gathered more than 11,000 users of Autodesk CAD/CAM software in Las Vegas last November 2018.

At the event, generative design technology was also shown to be more accessible and affordable, as indicated by Autodesk’s approach to making this technology available. For example, all subscribers to Fusion 360, the company’s family of design and manufacturing tools integrated on a common, cloud-based platform, can apply “cloud credits” to run a generative design study and, optionally, download a result for additional credits. Thus, customers pay only for what they use, the company points out.

Perhaps most importantly, the concept of generative design is evolving. Autodesk spokespersons noted that rapidly evaluating thousands of design possibilities yields more than the optimum ones to consider. It also sparks the human imagination. Users are reporting that applying the software helps them “come up with something we hadn’t thought of,” including ideas for new additive-manufacturing technology and the practical capabilities of existing, at-hand technology such as CNC machining.

To Boldly Go …

When the prototype concept lander made its appearance on stage before the assembled audience of AU attendees in Las Vegas, it was accompanied by pounding music and pulsating lights — a dramatic way to highlight the significance of the design innovations it embodied. It is hard to imagine how different the arrival of an interplanetary lander on a distant moon or planet might be in the future. Europa, for example, interests scientists because its size and unusual characteristics have led many of them to suspect that under its frozen crust, it might hold a larger volume of water than exists on earth. There is speculation it might support life and perhaps could sustain a human colony someday.

These possibilities have prompted the National Aeronautics and Space Administration (NASA) to consider requirements for a mission to explore such enticing destinations. Although a mission of such ambition might be a decade or more in the future, NASA has already tasked its Jet Propulsion Laboratory (JPL) to design and construct a lander for this level of scientific exploration. In its ultimate form, a suitable lander will have to be unlike any spacecraft so far created. It will have to withstand the forces of a rocket-propelled launch, endure a years-long journey through space and then survive a harrowing descent to the interstellar body’s surface.

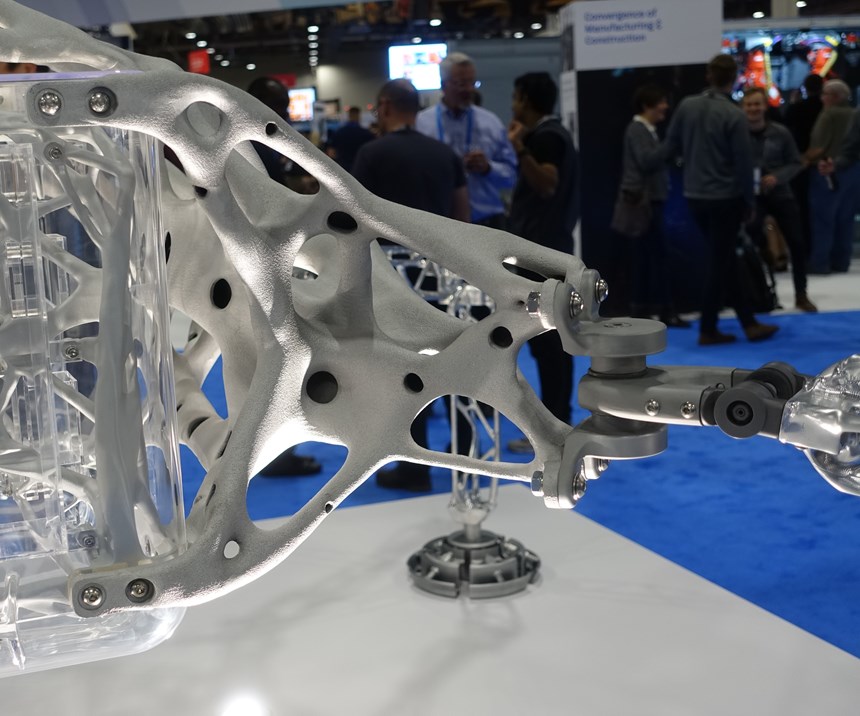

The current design concept for this lander and its prototype were developed as part of a multi-year collaborative research project between JPL and Autodesk. The lander will have to be extremely strong yet light to carry the maximum amount of scientific instruments, testing equipment and experiment kits. As conceived, this gear will be contained in a crate-like cargo unit resembling an oversized suitcase that will be carried in a cage-like frame incorporated in a self-propelled transporter. At each corner of the transporter, a jointed leg suggests a form of robotic locomotion that keeps the cargo unit off the ground. In appearance and motion, the prototype resembles a giant crab.

As always, JPL has a strong interest in finding, developing and applying the latest in manufacturing technology for its projects. Within JPL, its Atelier division is the team charged with trying new approaches and processes, and its recommendations are passed on to teams working on specific missions. This division is collaborating with Autodesk to evaluate generative design for the proposed lander.

Because weight is a major factor, JPL is exploring how to apply generative design software to develop the critical components for the transporter, which include the main cargo frame, the upper and lower “legs,” and other structural members.

The latest version of Autodesk’s generative design software includes new capabilities that sort through design possibilities that reflect manufacturability considerations. This enables engineers to compare how different manufacturing processes influence how easily, quickly and cost-effectively components can be produced. Formerly, generative design software most often pointed to possibilities that were producible only by means of additive manufacturing processes, because the resulting organic, nature-like forms that were commonly created did not lend themselves well to processes such as machining, casting or fabrication. By applying constraints that sort design possibilities according to limits that favor selected processes, design options can be evaluated in a new light. The results can be surprising and significant in terms of the importance of generative design software as a decision-making tool.

In fact, JPL’s experience with this enhanced software is a case in point. Certain components could be designated as candidates for additive manufacturing processes, whereas other components could be designated as candidates for multi-axis machining or casting in 3D-printed sand molds.

Similarly, additional capabilities now incorporated in generative design software are making it a more useful tool in other design and manufacturing environments. For example, developers of products for today’s consumer markets pay close attention to the looks of a product. Here again, generative design software now has an answer. Whereas components designed with earlier versions of the software were likely to have an awkward or unattractive appearance because they sometimes resembled a collection of strung-together bones or twigs, it is now possible to smooth and sculpt these shapes automatically into aesthetically pleasing configurations so that parts take on a more appealing, streamlined appearance.

Constraints Are Liberating

At the AU event, Mark Davis, Autodesk’s senior director of industrial research, began his technical presentation by pointing out that this lander project is the first in which design challenges and manufacturability constraints were identified and addressed at the outset. This was a unique opportunity to evaluate generative design’s benefits.

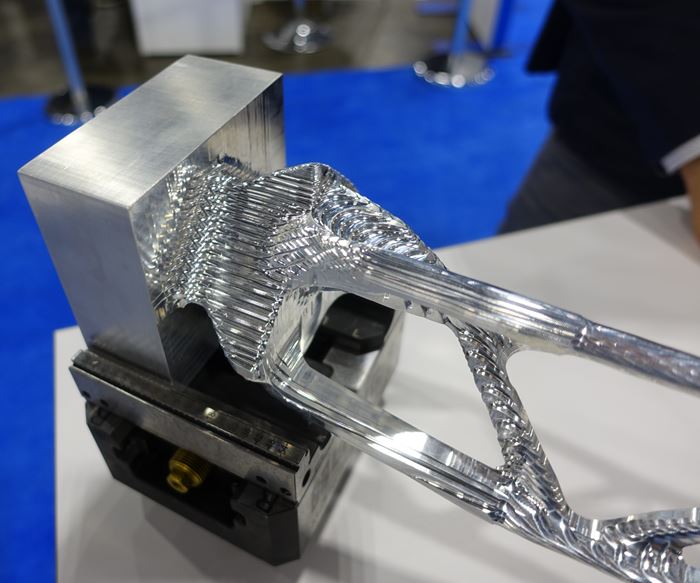

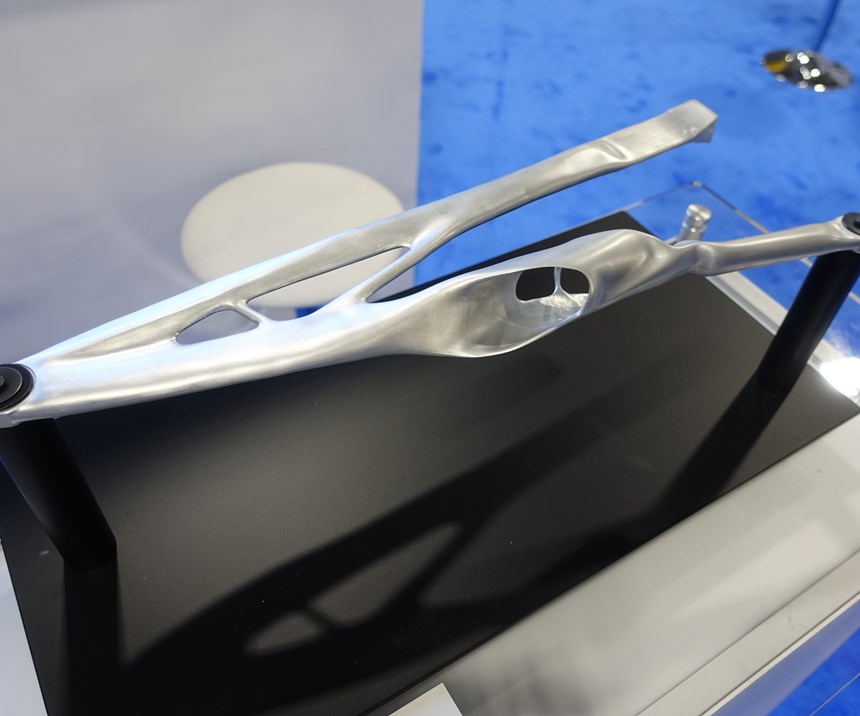

What caught the attention of JPL engineers, he said, was an earlier project in which Autodesk partnered with Mercedes AMG Performance Motorsports to redesign components for a Formula One race car’s rear outboard suspension. For this project, Mr. Davis and his team had developed a custom version of the generative design software to solve for multiple manufacturing constraints at once. The goal was to design lightweight components that could meet the car’s aerodynamic performance requirements yet be producible with existing subtractive manufacturing equipment such as a CNC machining center. One test part, an aluminum lower wishbone suspension arm, exemplified the potential for applying manufacturability constraints in generative-design studies.

The resulting design was produced on a five-axis machining center. This part, and the original humanly engineered version, were displayed side-by-side near the lander prototype at the AU event. This was significant because more advanced versions of the software could be applied to solve the larger and more sophisticated problems posed by the lander project, Mr. Davis explained. “We now have the ability to help our customers solve for multiple manufacturing constraints simultaneously, which adds CNC machining and casting options in addition to 3D printing.”

Subsequently, the JPL team explored the use of this experimental generative design technology for lander components. For example, one of the generatively designed components is an internal structure intended to secure scientific payloads inside the radiation shielding vault. This structural component was produced by means of metal additive manufacturing. It is not a large piece, but its complexity makes it a good test case for additive processes.

The external structure that holds the vault itself was sand-cast using additively produced molds. Reportedly, this study showed that sand casting with additively-produced molds enables large, complex geometry to be manufactured as a monolithic casting, thus avoiding the need for heavy, bolted interfaces. In addition, sand casting accommodates an optimized hollow design with variable wall thicknesses. Therefore, the walls can be thicker in areas of the design under significant load and thinner in other areas to reduce weight.

The lander legs, in contrast, were generatively designed to be producible on a three-axis machining center using an indexing fixture for three orientations. Validation of this design by finite element analysis (FEA) and other virtual tests indicated that it met all strength and weight objectives. It was noted that no substantial reduction in weight could be obtained by producing it additively.

Overall, these studies indicated that generative design could reduce the total mass of the concept design by as much as 30 percent, thereby equaling or exceeding the benchmark that JPL set for evaluating the promise of this technology. Likewise, these studies showed that generative design technology is useful in evaluating two key aspects of manufacturability. They help determine not only the engineering practicality of a proposed project, but also its feasibility within funding and budgetary concerns that might favor existing, well-tested manufacturing resources.

Mr. Davis predicts that generative design’s strong association with 3D printing or additive manufacturing will give way to a broader appreciation of it as a tool to discern the value of other manufacturing processes. He reports that Autodesk is now developing options for evaluating plasma arc and abrasive waterjet cutting, carbon-fiber composites, tubular fabrication, and plastic injection molding.

Finally, Mr. Davis noted that a key benefit of generative design, over and above improvements in component performance characteristics, is how rapidly new designs can be iterated. “Most design teams typically take 2 to 4 months to revise a design,” he says. “Working with generative design, that process can take place in 2 to 4 weeks.”

Generative Design Rides On

When is 2.5-axis-machining more advantageous than machining with three (or more) axes? Generative design capabilities can now help a manufacturer answer questions like this, too. A striking example of this was offered by Stephen Hooper, vice president and general manager for Fusion 360, in his presentation at AU’s Design and Manufacturing keynote. Whereas other developments in generative design software were embodied in an exotic racecar or a futuristic moon lander, this example involved a much more practical means of transportation.

Mr. Hooper’s technical presentation focused on the experiences of Whill, a young company that has redefined the possibilities for mobility devices to assist people who have difficulty moving about on their own. As he explained, the innovations of this small but global company have transformed the heavy, ungainly motorized wheelchair into an attractive, highly maneuverable, easily transported device that gives the impaired new freedom and independence in and out of their homes.

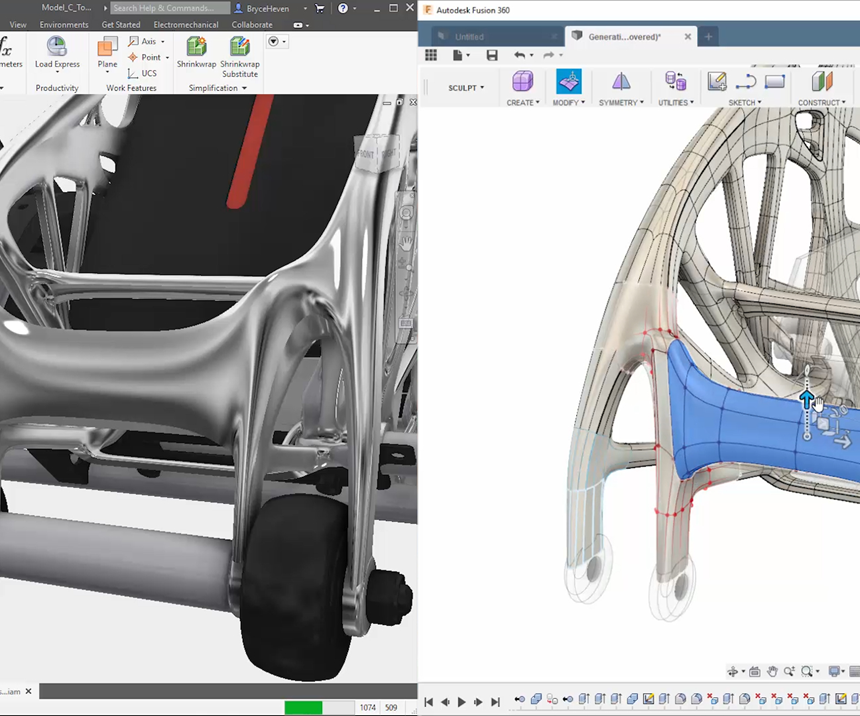

Recently, Whill undertook a redesign of its popular Model C1, a personal electric vehicle that can be separated into three modules for easy placement in the trunk of a car. The goal of this effort, Mr. Hooper said, was to make the new version even lighter, stronger and more functional. It was also an opportunity to explore how generative design technology could assist in this effort.

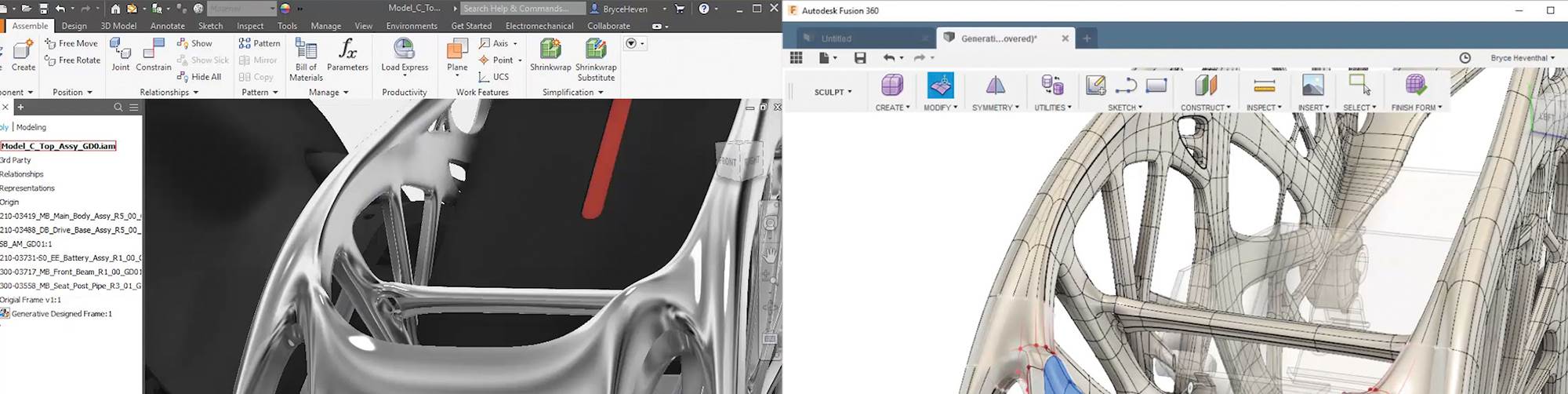

Mr. Hooper reviewed how major components such as the vehicle’s main frame could achieve significant improvements in strength and reduced weight using the new technology. In addition, other components were studied to see how Autodesk’s new styling tools to smooth and refine design results might give these highly visible vehicle parts a streamlined, stylish appearance. This is possible, Mr. Hooper explained, because generative design and Fusion 360 yields editable CAD geometry, which makes it easy to apply styling tools such as T-splines (mathematical modeling routines for generating smooth curved surfaces in CAD). Both components were constrained to be producible on five-axis machining centers.

Perhaps the most interesting segment of Mr. Hooper’s presentation was devoted to a close look at the results for the redesign of a rather inconspicuous but critical component, a study which Autodesk undertook as a proof-of-concept exercise. This component, a part of the hinged mechanism that supports the wheels and brake system, must function reliably to keep the vehicle operable. The bulkiness of the former, parametrically designed support was judged to be unnecessary for the appropriate safety factor. This original version, which had taken approximately 3.5 hours to design by an expert engineer, weighed approximately 390 grams.

When using generative software in the cloud to redesign this part, results were constrained for 2.5 and three-axis machining. Results (that is, a new design) were obtained in approximately 20 minutes for each constraint. The new three-axis part was calculated to weigh approximately 187 grams, whereas the 2.5-axis part would weigh about 204 grams. However, calculating the cycle times for the two different tool paths revealed a substantial difference in favor of 2.5-axis machining. This design could be 2.5-axis-machined in 35 minutes compared to 123 minutes for the three-axis design. (For reference, the tool paths generated for the original, parametric design involved 51 minutes of machining cycle time.) Mr. Hooper surmised that the 17-gram difference between the two generatively designed parts would not justify a longer cycle time.

The Digital Platform as Launching Pad

In closing, Mr. Hooper explained that generative design enables manufacturers to make trade-off decisions that balance market requirements, product capabilities and considerations for cost, quality and manufacturability. He also noted that manufacturers such as Whill can arrive at these decisions working in a unified, integrated Autodesk platform that includes Inventor, its 3D mechanical design and simulation CAD application and Fusion 360. Using Fusion 360 to access Autodesk’s generative design technology, the engineers can stipulate manufacturing processes, define design requirements and materials, and then leverage the power of cloud computing. Clearly, Mr. Hooper concluded, generative design should not be of interest primarily to manufacturers with a strictly additive mindset. As manufacturers acquire new options for making parts, they must also acquire the means to make the best decisions about applying these options.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More