UNITED GRINDING North America, Inc. - OH

2100 United Grinding Blvd.

Miamisburg, OH 45342 US

937-859-1975

info@grinding.com

grinding.com

IS THIS YOUR COMPANY?

Video Gallery

Setting The Tone for the Service Summit 2024

Our field service technicians gathered this year to sharpen their skills, drive product innovation, and strengthen teamwork.

BLOHM MC7

Unveiling the High-Performance BLOHM MC7 Grinding Machine at IMTS 2024 We're excited to present the BLOHM MC7—a ...

WALTER HELICHECK NANO Live at IMTS 2024 | Precision at Its Finest

Explore the WALTER HELICHECK NANO, debuted live at IMTS 2024! Specifically designed for ultra-precise micro tool ...

IMTS 2024 - UNITED GRINDING North America Booth Showcase

If you weren't able to make it to IMTS 2024, check out this video to get a glimpse at the UNITED GRINDING North America booth!

As Seen On Modern Machine Shop

UNITED GRINDING North America, Inc. - OH Supplies the Following Products

- CNC Software, Stand-alone

- Coordinate Measuring Machines (CMMs)

- Creep Feed

- Cylindrical OD

- Gear Grinding Machines

- Internal Cylindrical

- Maintenance & Repair

- Profile

- Super (Micro) Finishing Machines

- Surface, Reciprocal Table

- Surface, Rotary Table

- Thread

- Tool, Cutter & Drill Point

- Universal (ID/OD)

- Vision Systems

Trade Names Offered by UNITED GRINDING North America, Inc. - OH

- Maegerle

- Helitronic Basic

- Walter

- Helitronic Vision

- FlexGrind

- Helitronic Micro

- StuderGrind

- Prokos

- Kronos

- Mägerle

- Helitronic Diamond

- Mikrosa

- Compact

- Studer

- Planomat

- Helicheck

- Schaudt

- Jung

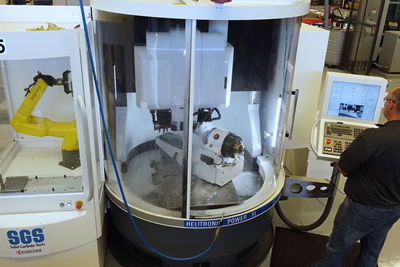

- Helitronic Power

- EWAG

- AEROMAT

- Blohm

- CamGrind

Editorial, News, and Products

-

United Grinding Apprenticeship Program Receives Recognition From US Department of Labor

United Grinding North America now has the opportunity to partner with the U.S. Department of Labor to shape apprenticeship expansion and diversification in the industry.

-

United Grinding Signs Agreement to Acquire GF Machining Solutions

United Grinding has signed an agreement to acquire the GF Machining Solutions division of Georg Fischer AG, aiming to establish a global presence in ultra-precision machining.

-

United Grinding Highlights Customer Successes

United Grinding is showcasing four customer success stories at its booth this year, highlighting real-life use cases for its technology.

-

United Grinding Solutions Enable Precise Production

IMTS 2024: United Grinding showcases a range of precision grinding solutions.

-

Studer's Automation, Entry-Level Solutions Take Center Stage

At its 2024 Music Motion Meeting, Studer AG showed off its entry-level line of grinding machines, as well as its newest universal loading system.

-

United Grinding Hires New Manager Director for Mexico Territory

Alonso Acevedo brings 27 years of experience in the machine tool industry, including 12 years on the end-user side and 15 years in various sales roles.

-

United Grinding's New Ranges Provide Economical Solutions

United Grinding’s Studer, Blohm and Walter brands are offering new grinding technology for job shops.

-

United Grinding Offers Four-Year Apprenticeship Program

The program enables participants to earn a full scholarship for an associate degree in automation and control technology with robotics.

-

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

-

Rebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

-

United Grinding Announces Support for the Reshoring Initiative

According to the Reshoring Initiative, the rate of reshoring job announcements has grown from 10,000 per year in 2010 to 350,000 per year in 2022.

-

United Grinding Expands Distribution Network in Mexico

Intermaq will represent United Grinding’s full line of equipment and expand the precision CNC grinding market in Mexico.

-

Studer Offers Entry-Level Grinding Machine

The S100 is suitable for grinding geometrically defined basic forms and contours for a wide range of parts, all of which can be generated with the machine’s interpolating axes.

-

Studer's New Grinding Machine Features Large Grinding Wheel

The S36 is designed for productive external grinding of chuck and shaft components, which can serve industries including die and mold, aerospace, automotive and more.

-

Non-Contact Blue-Laser Measurement System

Laser Contour Check provides high-precision measurement of various tool parameters on cylindrical tools with diameters from 1 to 52 mm.

-

Compact Tool Grinding Machine With a Big Impact

United Grinding’s small grinding machine makes a big appearance at IMTS 2022.

-

Operative System for Grinding Machines

United Grinding showcases digital operating systems at IMTS 2022.

-

Cylindrical Grinder Takes on Complex ID Operations

One of the centerpieces of United Grinding’s booth at IMTS is a grinding machine designed for ID grinding of hard materials.

-

United Grinding, Titans of CNC Launch Grinding Academy

The Grinding Academy offers free online courses to teach and train the next generation of machinists.

-

United Grinding North America Partners With Concept Machine Tool

The companies are partnering to provide tool grinding and measuring technologies to manufacturers in the Midwest.

-

Concept Machine Tool Appointed Distributor For United Grinding North America

United Grinding North America has appointed Concept Machine Tool as its exclusive distributor for cylindrical, surface and profile grinding.

-

United Grinding Offers Automation Solution for Radius ID Grinders

Studer roboLoad system is designed to offer seamless part integration for CNC radius internal grinding machines.

-

United Grinding Group Nominated for UX Design Award

The company’s C.O.R.E. solution for machine tool control and monitoring is nominated for the award, which recognizes outstanding user experience and is presented by the International Design Center Berlin.

-

United Grinding Offers Compact, Automated Parts Loading

The Studer RoboLoad saves shop floor space while offering room for workpieces to be manually loaded on six trays within a small work area.

-

Enhance Production Monitoring With United Grinding's New System

United Grinding C.O.R.E. is said to open up new possibilities for networking, controlling and monitoring the production process; it brings the user experience of operators into the world of the smartphone generation.

-

United Grinding Group Set to Unveil New Brand

United Grinding C.O.R.E. will be unveiled in October at EMO 2021 in Milan.

-

Guarding Against Cyberattack Is a Drain on Machining Capacity

The Colonial Pipeline shutdown was a warning about the dangers of malicious use of data networks. However, as the full value of Industry 4.0 becomes apparent, isolating CNC machine tools from networks will be seen as an increasingly costly way to protect manufacturing from threats.

-

United Grinding's Digital Solutions Aid Maintenance and More

United Grinding’s Digital Solutions app and software can facilitate process optimization and simplify maintenance tasks through monitoring and conference capability, respectively.

-

How Advanced Grinding Technology Leverages Capabilities Beyond Grinding

United Grinding shows how rethinking traditional grinding technology and combining manufacturing processes can extend the role of grinding and make grinding machines more productive.

-

Walter Helitronic Raptor Tool Grinder Resharpens Rotationally Symmetrical Tools

The Walter Helitronic Raptor from United Grinding is designed for grinding and resharpening rotationally symmetrical tools for the metal and wood industries.

-

When Manufacturing Industry Events Are Delayed

Walter is moving to a digital product launch Wednesday at 10 a.m. CET (5 a.m. ET) in light of the coronavirus causing a significant delay for an in-person launch.

-

Ewag Laser Line Ultra Fabricates Micro Tools from Hard Alloys

As products grow thinner and lighter to meet the needs of the electronics, medical and micromechanics industries, United Grinding and Ewag have developed the Laser Line

-

Swiss Grinding Technology in Motion

During a recent open house at Studer’s headquarters in Switzerland, the company highlighted advances in cylindrical grinding technology including automation solutions to enable long stretches of unattended operation.

-

United Grinding Appoints President, CEO

Markus Stolmar has worked more than 20 years with the company in executive positions for its Walter and Ewag brands.

-

Top Shops Then and Now

Altech Machining was a Top Shops winner in our inaugural benchmarking survey in 2011. So what’s the shop up to now?

-

July 2019 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on grinding and abrasive machines and equipment.

-

Studer S131R Grinds Hard Materials Typical of Dies

United Grinding’s Studer S131R, a radius internal cylindrical grinding machine, is well-suited for making dies out of hard materials such as tungsten carbide and ceramics.

-

Studer Expands Universal Cylindrical Grinder Series

Studer introduces new features to its external universal cylindrical grinding machines S33 and S31, which now provide additional distances between centers.

-

Industry News of Note: April 2019

EDM maker starts a new chapter in Ohio, Tornos to host a grand opening in Chicago and other industry news.

-

10 Ways to Think Differently about Robotic Automation

Take another look: A lot is happening in and around robotic automation. What robots might mean for machining and manufacturing is getting ready to change.

-

Time-Lapse Video Demonstrates Total Lifecycle Support

United Grinding shows what it takes to tear down and rebuild a grinding machine to support its philosophy of total lifecycle solutions.

-

July 2018 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on various grinding machines and equipment for all sorts of applications.

-

Grinding Center's Spindle Speed Promotes Precision

IMTS 2018: United Grinding offers the Magerle MFP 51 grinding and machining center designed for productivity, flexibility, safety and performance.

-

Grinding Machine Designed for Single-Part, Series Production

IMTS 2018: The Studer Favorit CNC cylindrical grinding machine, available through United Grinding, handles long workpieces and has a center distance of 1,600 mm (63").

-

Grinding Machines Increase Workpiece Space, Enhance Rigidity

IMTS 2018: United Grinding is displaying the Walter Helitronic Power 400 and Helitronic Power Diamond 400 grinding machines, both said to offer 35 percent more workpiece space.

-

Grinder for Grinding Carbide Inserts Incorporates Robot

United Grinding has released the Ewag Profile Line, an indexable carbide insert grinding solution.

-

Grinder Suited Either to Universal, Production Manufacturing

The Planomat HP 412 from Blohm is an efficient grinding machine offering fast infeed speeds and accelerations as well as grinding drives as high as 24.5 kW

-

United Grinding Names Regional Sales Managers

Michael Hilbert and Doug Smith will provide support to customers in the Central and Southeast regions, respectively.

-

Redesigned Grinding Machines Feature Improved Stability

United Grinding Group has redesigned the Walter Helitronic Power 400 grinding machine and Power Diamond 400 grinding and eroding machine.

-

Universal Cylindrical Grinder Handles Long Workpieces

Studer has introduced the Favorit CNC universal cylindrical grinding machine with a center distance of 1,600 mm (63") to handle long workpieces.

-

United Grinding Unveils New Ohio Facility

The new facility will consolidate the company’s offerings in a single location in Miamisburg, Ohio.

-

United Grinding Opens New U.S. Headquarters

The Ohio facility is designed to increase efficiency and consolidate the company’s various grinding machine, automation and rebuilding departments for complete lifecycle support and faster response times.

-

Centerless Grinder Reduces Cycle Times for CBN Workpieces

United Grinding introduces its Mikrosa Kronos S 250 centerless grinding machine, which uses angular plunging designed for corundrom and CBN grinding in high precision and mass production.

-

Manufacturing News of Note: July 2017

A big R&D agreement looks at additive for structural airplane components, Autodesk appoints a new president and other industry news.

-

United Grinding Closing Virginia Facility, Consolidating in Ohio

The move is expected to increase efficiency and part turnaround time in North America.

-

Multitasking Grinding, Machining Center Promotes Productivity

As a five- or six-axis system, the Mägerle MFP 50 CD grinding and machining center from United Grinding is offers capability to mill, drill and grind challenging workpieces in a single clamping.

-

Compact Production Grinding Machine and Automation Trends

Three years after the introduction of this cylindrical grinding machine, options are being added to further facilitate automated part loading.

-

When Grinding Is Like Turning

This shop leverages a high-speed peel-grinding process that resembles turning to effectively grind challenging materials such as carbide. Inherently low grinding forces mean high material-removal rates are possible.

-

United Grinding Breaks Ground on New U.S. Headquarters

The large facility represents a consolidation of resources, as the company’s two U.S. locations have heretofore segregated their equipment focuses.

-

Grinding Continues to Break New Ground

That, I think, is the significant story behind the news of United Grinding's recent groundbreaking ceremony for a new North American Headquarters to be constructed in Miamisburg, Ohio. Grinding technology is moving into new applications and markets, so it is no exaggeration to say that grinding continues to break new ground.

-

Internal Cylindrical Grinding Machines Extend Line’s Workpiece Capacity

United Grinding has added three radius internal cylindrical grinding machines to its Studer lineup.

-

Slideshow: Motion Meeting a Mega Success

The introduction of a sleek new super-efficient assembly line was just one of the highlights of this year’s conference focusing on United Grinding’s constant pursuit of machining excellence.

-

Motion Meeting a Mega Success

The introduction of a sleek new super-efficient assembly line was just one of the highlights of this year’s conference focusing on United Grinding’s constant pursuit of machining excellence.

-

February 2016 Product Spotlight Slideshow: Grinding

This month’s Modern Equipment Review Spotlight focuses on grinding machines of various capacities.

-

Shop Transitions to Aerospace Work with CNC Grinder

J&E Precision Tool met increased demand for complex, high-precision parts with the Studer S33 grinder from United Grinding, leading to improved workflow, part quality, machine utilization and quoting.

-

October 2015 Product Spotlight Slideshow: Laser Machining

This month’s Modern Equipment Review Spotlight focuses on laser cutting, welding and marking machines.

-

Five-Axis Machining Center with Laser Cuts CVD-Diamond Tooling

United Grinding has extended its line of Walter Ewag technologies for cutting tool production to include the Laser Line Ultra five-axis machining center that incorporates ultra-short pulse laser technology.

-

Lessons in Grinding

A two-day event at United Grinding’s headquarters highlighted a range of new grinding strategies and approaches for many of today’s challenging applications.

-

Cylindrical Grinder Provides Three Parallel Spindles

Available from United grinding, the Studer S122 internal cylindrical grinding machine is designed for the production of small to medium-size workpieces in small- and large-scale production.

-

Garage Shop Evolves into CNC Tool Grinding Specialist

This tool grinding shop was able to transform itself into a specialty cutting tool producer with the adoption of a few advanced CNC tool grinding machines.

-

Cylindrical Grinding Technology in Motion

United Grinding's annual Motion Meeting in Thun, Switzerland, highlights the group’s latest developments in cylindrical grinding. News from this year’s event includes the introduction of new models that broaden the range of ID and OD cylindrical grinding in the Studer line.

-

February 2015 Product Spotlight Slideshow: Grinding

Click through this slideshow for a sampling of grinding equipment, ranging from hand tools and abrasives to complete grinding systems.

-

Internal Cylindrical Grinding Machine Accommodates Longer Workpieces

Available from United Grinding, the Studer S141 universal internal diameter (ID) cylindrical grinding machine enables internal grinding of longer workpieces such as those used in the machine tool, drive element, aerospace and toolmaking industries.

-

Wire EDM for Dressing Metal-Bonded Wheels

The Studer WireDress system, which uses the wire “spark erosion process” to dress a metal-bonded grinding wheel while it is still mounted in the grinder, makes using these wheels more efficient and economical.

-

CNC Grinder Shortens Lead Time for Specialty Tooling

Switching from manual grinding applications to CNC grinding applications with a Studer favoritCNC grinder from United Grinding helped ETW Inc. reduce lead times for custom HSK tooling.

-

Cylindrical Grinding Machines Equipped with A Axis

Available from United Grinding, the Studer S41 and S22 cylindrical grinding machines now feature an A axis for thread grinding.

-

Cylindrical Grinding Machine Tour Launches

United Grinding recently introduced its Studer S11 small-parts production grinding machine to the North American market on the USS Yorktown. You’ll soon be able to see it, too, as it embarks on an eight-city tour, which started Feb. 19.

-

Compact Cylindrical Grinding Machine for High Production

United Grinding recently introduced its Studer S11 small-parts production grinding machine to the North American market. An online video demonstrates an interesting cam-actuated loading system that’s available with the machine.

-

Five-Axis Profile Grinder for Aerospace Applications

United Grinding’s Blohm Aeromat profile grinder is well-suited for flexible, high-performance grinding applications.

-

Cylindrical Grinder Designed for Micro Components

Available from United Grinding, Studer’s S11 cylindrical grinding machine is designed for the production of micro components such as injection nozzles for diesels.

-

Centerless Grinding Machine Grinds Medium-Sized Shafts

Available from United Grinding, the Mikrosa Kronos L 550 centerless external cylindrical grinding machine is designed for machining medium-sized shafts measuring 400 to 545 mm long for automotive applications.

-

An (Un)common Approach

Although differentiation is key to competitiveness, successful manufacturers seem to have a lot in common. Some of these shared principles were on full display during a recent tour of Studer’s plant in Switzerland.

-

Grinding Machine for Toolmaking, Precision Engineering

The Studer S33 from United Grinding is designed for grinding medium-sized workpieces in individual and batch production for toolmaking and precision engineering applications.

-

Internal Grinding Machine Features Four Spindles

The CT960 universal internal grinding machine from Studer features a fully interpolating B axis and four spindles for complex grinding tasks.

-

Five-Axis CD Grinding Center Features Automatic Grinding Wheel and Toolchanger

United Grinding’s Mägerle MFP 50 five-axis CD grinding center is a flexible multitasking grinder that features an automatic grinding wheel and toolchanger.

-

Grinder Offers Precise, Single-Setup Production

Studer’s S33 cylindrical grinding machine from United Grinding Technologies provides rigidity and precision along with the flexibility to complete multiple operations in a single setup.

-

United Grinding Celebrates 30 Years in Virginia Location

United Grinding recently celebrated 30 years in its Fredericksburg, Virginia location with a ribbon-cutting event opening a newly expanded and renovated facility.

-

Grinder Features New Guideway Design

StuderGuide combines the advantages of hydrostatic and hydrodynamic guideways.

-

Wire EDM with a Twist

Wire EDM units that swivel a horizontally guided electrode wire in a CNC-controlled E axis give this shop the workpiece clearance and flexibility to produce complex, high-precision PCD-tipped cutting tools.

-

United Grinding Expands ID Grinding Capabilities

Studer’s CT 730L internal cylindrical grinding machine is suited for small- to medium-sized ID grinding applications.

-

Grinder’s Hybrid Hydro Guides Offer Speed, Precision

A hybrid guideway system on Studer's new S41 universal cylindrical grinder is designed to ensure the linear motors driving the machine’s axes are employed to maximum effect.

-

Cylindrical Grinding Machine Boosts Metal Removal Rate

The S41 CNC universal cylindrical grinding machine is designed to increase precision, surface quality and metal removal rates while decreasing cycle time.

-

Cylindrical Grinder Built For Rigidity, Precision

The Studer S41 CNC universal cylindrical grinder designed for precision, high removal rates and short cycle times in complex grinding jobs.

-

Advanced Grinding, Plain and Simple

Advanced grinding equipment gives this shop the flexibility and automation it needs to serve customers with either rapid-response or high-volume jobs.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Wear Compensation Ensures Accurate Wheel Contours

Profile grinder manufacturer Blohm Jung's GEOID system automatically compensates for wear in diamond dressing tools. By removing variables that require operator attention, the system is said to ease wheel dressing, ensure accurate profiles and extend the service life of dressing tools.

-

Universal Cylindrical Grinding Machine

Studer’s S33 universal cylindrical grinding machine said to provide low cost per part during external and internal cylindrical grinding of small and medium-sized workpieces in a single clamping. The machine is designed for both single-part and large-series production runs and is suited for toolmakers in job shops and manufacturers.

-

Hard Turning And Cylindrical Grinding Were Made For Each Other

Combining different machining processes on the same platform has been a major theme in machine tool design for two decades or so. The Studer S242 combines cylindrical grinding and hard turning. A look at this machine shows that both of these machining processes benefit when they share the same platform.

-

The Returns On Automation

Machine tool automation, particularly grinding machine automation, offers various returns on investment. Different shops notice different advantages, and sometimes shops overlook important benefits when they are deciding whether to automate.

-

The Case For Hydrostatic Ways

Moving on oil can let a grinding machine deliver more power along a smoother pass.

-

In It For The Long Haul

Curt Reed uses advanced grinding techniques in the pursuit of short-run, sub-micron work that other shops can’t perform or won’t attempt. His shop’s commitment to its customers is reflected in the high level of equipment sophistication and applied grinding acumen.

-

Making Chips Vs. Making Value

In a cycle that is 90 percent grinding and 10 percent more basic metal cutting, letting the grinder perform the last 10 percent may make sense.

-

Cutting With A 0.001-Inch End Mill

JPL’s Space Instrument Shop does this routinely, but it takes some special equipment and some unusual procedures. Above all, it takes patience.

-

Blade Grinding’s Need For Speed

A grinding technique akin to high speed machining offers an alternate method for grinding nickel-alloy blades and vanes used in turbine engines.

-

Accuracy Of Grinding Cell Eliminates Selective Assembly Of Bearings

Following a sustained period of growth, 600 Group subsidiary Gamet Bearings has invested in a new grinding cell to increase capacity, improve bearing accuracy, reduce costs and improve both process consistency and customer satisfaction.

-

Milling On A Grinding Machine

A grinding machine is not a machining center, but it can sometimes take on milling and drilling (or even turning) to make the overall process more efficient.

-

CNC Grinder Helps Start A Business

This Cleveland grinding shop owner discusses the challenges and rewards of starting a business in downtimes, and what it takes to stay competitive.

-

A Simpler Way To Automatically Load Grinding Machines

Custom automatic loading systems for grinding machines often lack the flexibility to allow quick job change-overs. These off-the-shelf loading systems were designed with intuitive set up in mind.

-

Technology And Skill Are Keys To Mold Shop Success

The domestic die/mold industry is today going through considerable change-a good deal of which is being driven by an urgency to become more competitive coupled with advances in technology. Here's how one shop combines skill and technology to be more than just competitive, but to excel and grow.

-

Grinding Shop Steps Up To CNC Machining

When Absolute Grinding shifted gears to CNC machining, the company saved a significant amount of time. The new machines were capable of performing many tasks simultaneously, making the shop more efficient.

-

Grinding Carbide--A Niche Within A Niche

If one must pick a manufacturing specialty, grinding carbide might not be the first choice because it’s perceived to be very difficult. RPM Carbide Die, however, has worked the material for nearly 40 years and, as specializing seems increasingly to be the order of the day, this northern Ohio shop is in a good position to thrive.

-

Hybrid Grinders For High-End Parts

This manufacturer now applies hybridization to the task of machining complex parts that require flexible grinding configurations. In addition to ordinary face grinding, for example, these machines also have the capability to grind bores, diameters and tapers.

-

Grinding In Lean Operations: Setup Makes The Difference

Find out how these grinding centers helped this major aerospace supplier become more efficient and reduce waste.

-

Gearing Up With CNC Grinding

By adding a CNC OD/ID grinder, this California gear manufacturer brought a lot of farmed-out work in house, improved quality, slashed lead times—and saved money.

-

Between Centers And Centerless Grinding In One Setup

It sounds like a contradiction in terms-between centers and centerless grinding on one machine. But for some categories of workpieces, it's a viable production process that can yield machining time reductions of 45 percent over separate grinding operations.

-

Shop Adds CNC Grinding To Its Mix

Of all the metalworking processes, grinding is probably the most application specific. In a job shop environment, however, flexibility is the key to successful grinding. Here's a look at how one captive job shop successfully transitioned from manual to CNC grinding while standardizing its grinding process parameters to accommodate the demands of low volume, high mix production requirements.