Grinding has a number of inherent advantages compared to other machining processes. Speed is not one of them. That’s not to say speed isn’t important in grinding applications—quite the contrary—but in general terms, faster processing isn’t high on the list of factors that draw users to grinding technology in the first place.

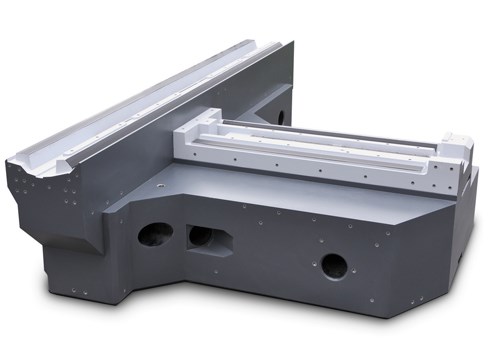

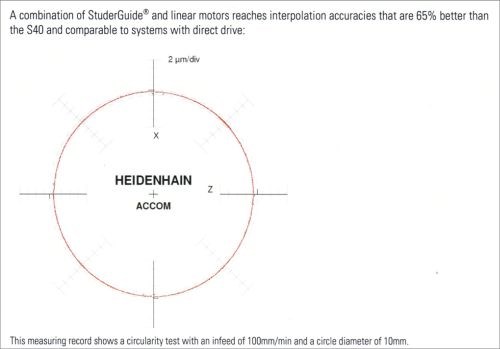

This principle wasn’t lost on Studer when the Swiss company unveiled its new S41 universal cylindrical grinder earlier this year. Although moving the longitudinal and cross slides as fast as 66 feet per minute is a major benefit of the machine’s direct-drive linear motors, it is another feature that ensures this speed doesn’t come at the expense of precision or repeatability: a new type of guideway system called StuderGuide. According to the company, this system’s hybrid design incorporates the advantages of both hydrostatic and hydrodynamic guideways to keep the slides on-target, whether stationary or in motion.

Considering the fact that the S41’s linear motors feature scales with 10-Nm resolution, one might wonder why precision and repeatability would be a concern at all. The answer is that applying linear drives to a universal grinder like the S41 generally involves a different set of priorities than applying them to other types of machines, says Hans Ueltschi, vice president of cylindrical division sales at United Grinding (Miamisburg, Ohio), which represents Studer in the United States. Compared to milling, for example, the speed of a cylindrical grinding process tends to be more inherently limited, he says. As a result, the benefits of driving axes faster generally apply more to traverse time—moving the wheel to a dressing unit, for example, or moving the slide to provide clearance for wheel indexing.

Consequently, a hydrostatic system that completely separates the moving element from the guideway with a consistently pressurized film of oil might seem ideal because it would eliminate friction. However, in terms of actual metal removal, a grinder’s ability to maintain a certain position or stop in the same place repeatedly is more important than traverse speed, Mr. Ueltschi says. At the speeds provided by linear drive, sliding on a film of oil with virtually no resistance might actually impede this ability. A hydrodynamic system, in which some contact with the guideway occurs when the moving element is accelerating, decelerating or stationary, would provide more resistance. However, that would come at the expense of advantages that characterize hydrostatic systems, including improved tolerance for differing pressures on the guides as well as reduced wear and maintenance.

In designing the S41, Studer sought to strike a balance. The result is a flat, V-shaped guideway that is partially hydrostatic and partially hydrodynamic. Although Mr. Ueltschi is tight-lipped on the exact configuration of these ways, he says combining the advantages of both systems makes the linear drives more effective.

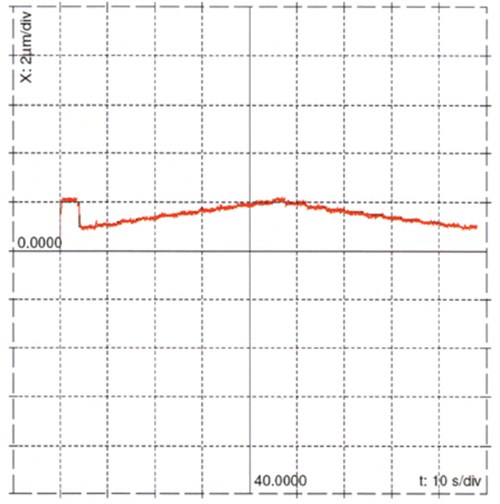

Like a hydrodynamic system, StuderGuide offers damping in the direction of movement and eliminates “floating” of the slide, he explains. Like a hydrostatic system, it eliminates the “stick-slip” effect, reduces guideway wear, requires little maintenance, and tolerates differing amounts of pressure without adjustment—a useful advantage for manufacturers working with a variety of workpiece sizes and weights. Also notable is the fact that the slides rest completely on the guideways throughout the entire 37.4-inch traversing range, resulting in straightness of less than 0.0001 inch. Taken together, these features ensure that StuderGuide meets the company’s goal of freeing the linear drives and high-resolution scales to provide the precise, fast slide positioning for which they were designed, Mr. Ueltschi says.