Compact Production Grinding Machine and Automation Trends

Three years after the introduction of this cylindrical grinding machine, options are being added to further facilitate automated part loading.

Share

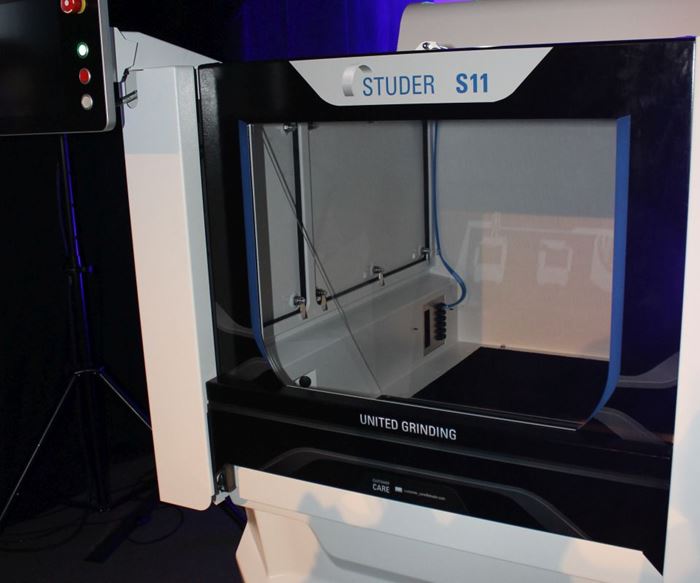

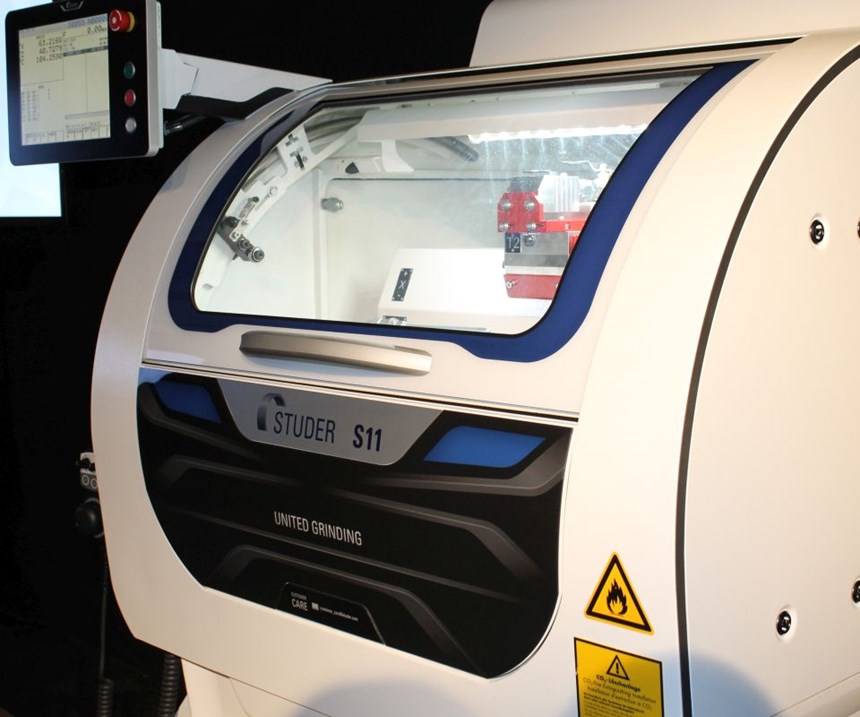

During its annual Motion Meeting, Switzerland-based Studer, member of the United Grinding Group, unveiled an updated version of its high-production Studer S11 cylindrical grinding machine which looks quite different: the enclosure appears less sleek than the original machine, which was introduced in 2014, but offers distinctive advantages for automated production. It is specifically designed for top/vertical loading for interlinked production processes in which the machines are loaded and unloaded via portal cranes. It features an automatic loading hatch for top loading, an automatic sliding door in the front and generous openings on the right and left side of the machine.

According to Studer Managing Director Fred Gaegauf, Studer delivers around 20 percent of its machines worldwide with automation today. In the U.S., the percentage of automated machines is around 6 to 8 percent, with increasing demand, Studer Sales Director Martin Hofmann added. The level of automation demand is increasing because many SMEs increasingly demand “simple” automation solutions such as part loaders, and larger companies individually automate their machines in-house (such as Linamar, for instance).

Another reason for increasing demand is the U.S.-based automation team recently founded by United Grinding. With a local team responsible for automation solutions, handling systems are integrated in the United States and do not have to be shipped all the way from Europe, which means reduced import and transport costs.

As a result, IMTS 2016 saw United Grinding machines equipped with robots, among those a Studer S33. “We’ve seen an increased interest in robots, especially since we featured a collaborative automation cell at IMTS,” Mr. Hofmann says. “These robots have the ability to work side by side with humans, which makes safety fencing and associated devices obsolete. This also allows for the robotic automation cells that feature these collaborative robots to take up a fraction of the footprint of a traditional robotic cell.”

According to Mr. Hofmann, more and more smaller manufacturers in the United States are now showing interest in automation solutions. With the integration of vision systems as well as developments in automation-related technology, automation is now more flexible than ever. Smaller manufacturers, which have lower quantity lot sizes and low-volume/high-mix applications are seeing that automation technology can be successfully implemented in their facilities.

Furthermore, the ease of integration has improved over the years. FANUC and Kuka, for instance, have their own proprietary 3D programming tool. “Each of these programs allow the user to import models such as our grinding machines, postprocess gaging, deburring, wash station and conveyors,” Mr. Hofmann explains. “Once you set up a cell, you can begin programming the robot and visualizing the robot interaction with these machines and devices in real time. You can generate a programming code directly from the software. Once you build the cell on your shop floor you can use the code you generated from the program and import it to the robot controller.”

Other advancements that ease the implementation of robots and automation solutions are vision and laser technologies, which have come a long way in the last several years. For example, FANUC‘s 3D bin picking technology has developed into something quite usable over a broader spectrum of workpieces, Mr. Hofmann says. “As the technology gets better, we see the simplification of special fixturing or handling in the near future in regards to grinding applications.”

Additionally, the cost for robots has decreased. ABB Robotics, for example, manufactures its robots in China to cut down on labor costs, Mr. Hofmann explained. FANUC, on the other hand, has developed its infrastructure in the United States to cut down on shipping and logistics costs. These ideas coupled with lean manufacturing systems have led to robots being more affordable.

While the S11 with new automation-friendly design will be available in Q3 of 2017, there are a range of additional options for an extended range of applications available now. These include:

- FANUC 0i-TF control

- Nhuck workhead MT4 which goes along with a C-axis option

- High-speed grinding spindle

- New SBS balancing system with contact detection

- StuderGrind software with extension packages

The latest generation of the Fanuc 0i-TF control is compatible with the StuderWIN software solutions, which includes programming software StuderWIN Focus with its standard grinding cycles that include optimized input masks in which the user simply has to enter the application-specific grinding parameters.

According to Studer, the customer still has the opportunity to design part programs as flexibly as possible using micro functions. The uniform control platform is said to guarantee program consistency on all machines running Windows operating systems. This is regardless of whether the program is programmed directly on the control or is generated externally with StuderGrind.

The S11 uses no hydraulics and is designed for automated high-volume production of small, precision parts on a footprint of just 19.4 square feet, accommodating a 19.7-inch-diameter wheel with plunge angles of 0 or 20 degrees. The conversion to the new control in the S11 provides users with the option of high-speed grinding operations with CBN grinding wheels with up to 460 fpm (140 m/min). Up to now, users were limited to grinding speeds of 164 or maximum 260 fpm. Studer has designed a new high-speed spindle specifically for the S11.

The new chuck workhead MT4 comes with a spindle locking mechanism as well as an integrated control unit for the power chucking cylinder and an MT4 holding fixture with a spindle passage of 1 inch. The MT4 now offers a C-axis option with an integrated indirect or direct measuring system. In combination with the software modules StuderThread or StuderForm, the S11 is now ready for C-axis applications such as thread and form grinding. The machine is also suitable for peel grinding, turbo grinding wheels, thread grinding, bearing race grinding, and eccentric applications, according to the company.

The machine also features an SBS contact and balancing system. The contact detection system includes a noise cancelling system for reducing interference sources and works on eight frequency bands with auto-teaching to observe grinding level noise. According to the company, this combined system for contact detection by means of vibration measuring and for semi and fully automatic balancing of the grinding wheels reduces downtime thanks to less air grinding.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)