United Grinding Offers Automation Solution for Radius ID Grinders

Studer roboLoad system is designed to offer seamless part integration for CNC radius internal grinding machines.

Share

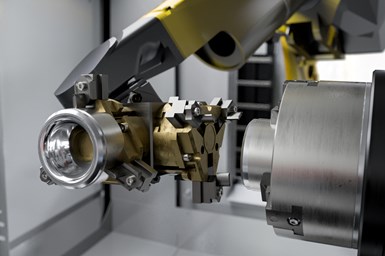

United Grinding has introduced the Studer roboLoad system, which it says gives manufacturers seamless part-loading automation for CNC radius internal grinding machines, such as the company’s Studer S121, S131 and S141.

The system comprises a FANUC M10-iD 10L robot, Siemens Simotion control, a 19" touch control panel and grippers with quick-change jaws that can be converted to a single gripper for parts weighing up to 15.4 lbs (7 kg) or a dual gripper for parts weighing up to 6.2 lbs (2.8 kg). It accommodates workpieces up to 10.24" (260 mm) in diameter and 0.39"-3.93" (10-100 mm) in length. It also comes with six trays for workpiece storage, each measuring 42.52 × 12.6” (1080 x 320 mm).

The company notes that loader integration has traditionally been difficult for these machines due to the height of their work heads and associated geometric restrictions. On the Studer S121, S131 and S141 machines, automatic B axes swivel in a range from -60° to +91°. Therefore, any automation must be able to exit the machine and give the B axis the freedom to swivel. The roboLoad offers this capability, meeting geometrical requirements and maintaining a small footprint, measuring 59.06" (1.50 m) wide. It also incorporates a setup wizard developed by automation specialists from Wenger so that it requires no programming knowledge on the part of the setter or machine operator.

Operators can bring up any grinding program for the workpieces, and the system processes them and places each one back in the same spot after machining.

Related Content

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.JPG;width=70;height=70;mode=crop)