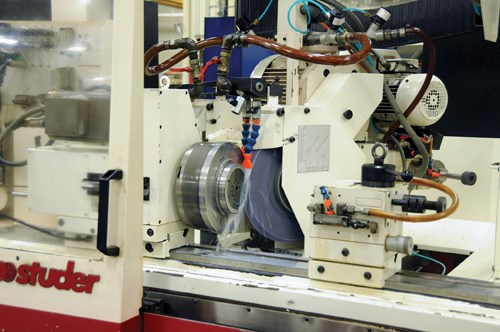

After 24 years of service, Minnesota Grinding’s Studer S20 still runs all day, five days a week. That lengthy track record is a testament to the reliability, rigidity and quality of service that have made Studer the brand of choice for the shop’s cylindrical grinding needs, says Harlen Gibbs, operations manager.

However, the shop’s latest grinder from Studer, a brand represented in North America by United Grinding Technologies (Miamisburg, Ohio), has provided advantages beyond those the shop has come to expect. In addition to being faster and more precise than comparable machines, the S33 universal cylindrical grinder provides the flexibility to perform operations that once would have required multiple machines in a single setup. “The machine has changed our philosophy,” Mr. Gibbs says. “It makes us more productive, more competitive and more cost-effective.”

Minnesota Grinding also thrives on flexibility in a broader sense. True to its name, the shop specializes in all manner of grinding operations, including centerless, thread grinding, lapping, honing, double-disc grinding and Blanchard and surface grinding. “If it uses grit and takes off material, we’re probably in it,” Mr. Gibbs says.

The company got its start in 1959 as a small tool grinding shop. Today, it operates out of a 42,000-square-foot facility in Crystal, Minnesota with 35 employees working across three shifts. Customers hail from sectors ranging from food processing to medical, automotive and aero-space. “We might be repairing a large roller for a roofing customer in one department while thread-grinding titanium bonescrews in another,” says David Schranck, human resources manager and infor-mation technology manager.

Prior to purchasing the S33, the shop relied primarily on three Studer machines for cylindrical work: the aforementioned S20—its first from Studer, purchased in 1988—and two S40s. All are more than sufficient for meeting customers’ tolerance and surface finish requirements, which tend to range between ±0.0001 and ±0.0004 inch and between 8 to 16 Ra, respectively. The machines can also grind just about any material, including aluminum, titanium, Hastaloy, stainless steels, Inconel, carbide and even plastic. In addition to sharing these traits, the S33 offers advantages of its own that have had a particularly broad effect on the operation, Mr. Gibbs says. “In the past, we would quote jobs based on running the part on multiple machines. The S33 enables us to do multiple diameters, faces and shoulders in one setup, on a single machine.”

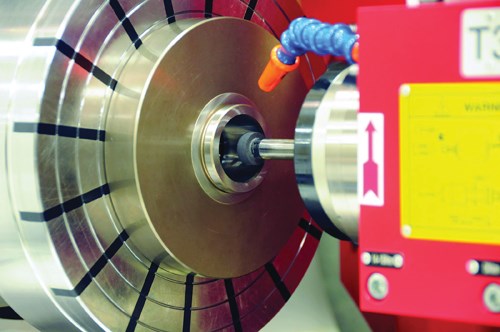

This flexibility is attributable in large part to a universal turret wheelhead equipped with both an external grinding spindle and an internal grinding attachment, Mr. Gibbs says. To ensure accuracy and ID-to-OD concentricity, this swiveling wheelhead uses a precision Hirth coupling with 1-degree indexing that repeats within 0.08 arcseconds. Also notable is the fact that wheelhead’s high-frequency internal grinding spindle can achieve speeds ranging to 120,000 rpm to facilitate grinding of very small bores, he says. Mr. Gibbs adds that the machine’s shoulder probe is especially useful for shaft parts that feature multiple diameters. By automatically determining shoulder location, the probe eliminates the need to measure every part and manually input locations into the machine before starting the cycle.

One such part that exemplifies the benefits of the S33 is a 16-inch-long shaft that requires grinding nine different diameters. These diameters step down in size from 1.5 inch at the largest to 0.75 inch at either end. Both ends of the component call for bearing journals that measure approximately 1 inch in diameter, while one end requires a keyway. “We grind the entire shaft in two operations,” says Joel Schoening, grinding technician and lead man. “I’ll chuck one end and grind six diameters from the shoulder down to the end. Then, I flip the shaft around and grind the other shoulder and the three remaining diameters.”

This particular part also showcases the machine’s precision, Mr. Schoening says. Meeting specification requires machining the shaft to a print tolerance of 0.0005-inch total runout. With other machines, the shop could achieve 0.0003 inch from diameter to diameter, resulting in a Cpk of 1.394. In contrast, the S33 holds 0.00005—50 millionths—from diameter to diameter, for a Cpk of 3.0134. “When I initially ran this part on the S33 and checked it with my tenths indicator, the needle didn’t even move,” he recalls. “I had another operator check the part, and he said my indicator must be broken. Then we checked with a 20-millionths indicator, turning the part slowly, and found it to be 50 millionths runout.”

The machine’s versatility and accuracy have helped Minnesota Grinding accommodate increasing customer demand, which has shown no sign of letting up since it installed the machine, Mr. Schranck says. In fact, within the past few months alone, the shop has added several other grinders and honing machines, retrofitted several existing models, and added a third shift. “We’re not the least expensive shop in town, but our customers do get what they pay for,” he notes. “This belief extends to the equipment we buy, and we plan to add at least one more Studer in 2012.”

.jpg;maxWidth=300;quality=90)