Share

Replacing older machines when they begin to show signs of age can be a waste of good equipment — many can still achieve excellent performance. Replacing brittle wires and old controls can rejuvenate older machines, an opportunity Kyocera SGS Precision Tools (KSPT) took advantage of for its Walter Helitronic Power Series tool grinders to keep the machines’ high tolerances and repeatability while improving computational speeds and compatibility with industry 4.0 technologies.

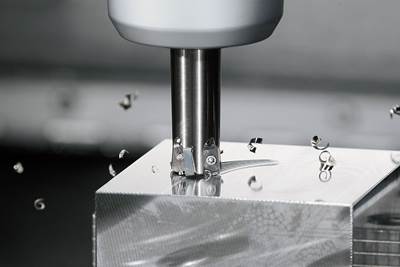

Only the heavy castings of KSPT’s Walter machines remain in the rebuilt versions. United Grinding replaced the mechanical parts, controls, electrical systems and automated loading system, improving speeds and long-term reliability while keeping the original machine’s exacting tolerances and repeatability. Photos courtesy of FANUC America.

Good Iron Foundations

KSPT has used its Walter machines to produce carbide rotary cutting tools for just over two decades. “Our tolerances for most of our high-precision products are within five ten-thousandths of an inch,” says Robert McLain, master tool grinder at KSPT. “That’s like a human hair, split 10 times.”

While the Walter machines were able to reach this standard into the 2020s, their controls were slowing and the wiring in the machines had become brittle. The old processors in the controls were also incompatible with newer versions of Windows, and therefore lacked key security updates.

For a company that networks its machines, this security weakness was intolerable. Equally dangerous, the brittle wires had gradually lost their coatings, exposing bare wire and risking electrical shorts. Repair parts for these legacy machines were also in short supply.

To eliminate these potential issues, KSPT contacted United Grinding about its Walter machine rebuild program, which replaces components in older machines with newer FANUC components.

“Good candidates for retrofits are machine tools used in the heavy construction, power generation and aerospace industries, since those machines are typically older, larger and made with what we call ‘good iron,’” says Jon Heddleson, general manager for factory automation at FANUC America. “Those types of machines are not easily replaced, and if they are, they can cost high six-figure sums or more to buy new.”

KSPT’s tool grinding machines qualified as “good iron,” so United Grinding kept their heavy castings while replacing the mechanical parts and electrical systems.

Tolerances and repeatability may not have changed, but the overall speed of the machine has improved, and internal replacements are more reliable for longer spindle uptime.

What’s Old is New Again

During the retrofit, United Grinding replaced the Walter machines’ servo and spindle motors, motor amplifiers, cables, and I/O units from their original designs to modern FANUC offerings. It also changed the older control to a FANUC 30iB CNC panel compatible with Windows 10 operating systems.

Not only does this new panel meet KSPT’s security requirements, it also improves compatibility with a wide range of Industrial Internet of Things (IIoT) technologies for purposes such as using machine monitoring systems to collect data. The processor is also much faster, reducing the time necessary for the control to determine the grinding wheel path. This is especially useful for the complex geometries presented by long, multi-flute tools, which can begin the grinding process significantly sooner.

The mechanical components benefit not only from improved stability in their construction, but from being parts in active production — replacements are less expensive and easier to find when necessary. Tolerances and repeatability may not have changed, but the overall speed of the machine has improved, and internal replacements are more reliable for longer spindle uptime.

Alongside these benefits inside the machine came a change from a mechanical loading system to a FANUC LR Mate robot. “Runout in the chuck is a big part of what we need to control for accuracy of the part,” says John O’Brien, manufacturing operations manager for KSPT. “The robot loader allows us to do this more accurately and more consistently than the mechanical loading operations.”

The older, gantry-style loader also ran into the same problem with legacy parts as some of the machines’ mechanical inner workings — repairs were growing difficult due to the unavailability of replacement parts.

Beyond rebuilds, United Grinding offers machine exchanges. In this program, companies exchange their older machines for already rebuilt ones from United Grinding’s warehouse, saving weeks of potential out-of-service time.

Continuing the Cycle

These rebuilds are typically between 70-80% of the cost of a new machine — a percentage that matters because of the high costs of tool grinding machines. Time spent getting these machines back up after they return is also important, and O’Brien reports that the rebuilds slot back into place nicely.

“Machines have come back and gone into operation within 12 hours from receiving the machine,” he says. KSPT’s tool grinding department has since contracted United Grinding to rebuild more of its Walter machines. “The rebuild program was a way to keep cost under control and still upgrade our machine to new processing speeds. It has been a big improvement.”

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

How Advanced Grinding Technology Leverages Capabilities Beyond Grinding

United Grinding shows how rethinking traditional grinding technology and combining manufacturing processes can extend the role of grinding and make grinding machines more productive.

Read MoreHigh Feed Rates or Deep Cuts - Which is Faster?

Comparing high-feed milling to other kinds, it is clear that the high feed and metal removal rates deliver on promises, but sometimes slowing down the feed and increasing the depth of cut will still end up faster.

Read MoreGarage Shop Evolves into CNC Tool Grinding Specialist

This tool grinding shop was able to transform itself into a specialty cutting tool producer with the adoption of a few advanced CNC tool grinding machines.

Read More

.jpg;maxWidth=300;quality=90)