Wire EDM with a Twist

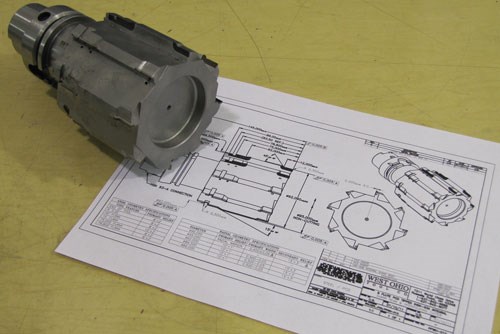

Wire EDM units that swivel a horizontally guided electrode wire in a CNC-controlled E axis give this shop the workpiece clearance and flexibility to produce complex, high-precision PCD-tipped cutting tools.

Share

Most wire EDM units feature a wire electrode that passes vertically from an upper to lower wire guide system. By moving the guides off center, the electrode wire can be tilted at an angle to a limited degree. West Ohio Tool, however, has two wire EDM units from Vollmer America (Carnegie, Pennsylvania) in which the electrode wire passes horizontally between opposing wire guides mounted on a swiveling cutting head.

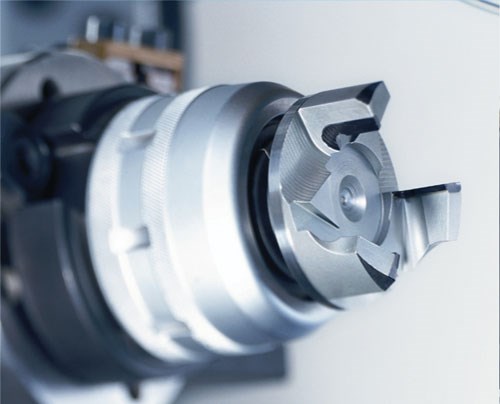

This unusual swiveling action, designated the E axis, is critical for producing the highly engineered and complex PCD-tipped cutting tools that are a rapidly growing business for West Ohio, a company that specializes in the design and manufacture of high-performance cutting tools. The ability to guide the wire horizontally and swivel it 180 degrees provides a greater range of motion than vertically oriented wire machines. This is important when cutting PCD edges on tools clamped in the programmable workholding spindle.

“Several trends are promoting the use of PCD cutting tools in the automotive and aerospace industries,” says Kerry Buchenroth, president of West Ohio. “These machines help us meet the growing demand for complex PCD-tipped cutting tools for high-silicon-content aluminum automotive components and carbon-fiber composite aerospace parts. More importantly, the machines enable us to design and produce innovative cutting tools that combine several cutting edges for multiple operations in one tool change.”

Lower Cost Per Part

“Lower cost per part” is the main value that West Ohio has strived to offer customers since its founding in 1989, Mr. Buchenroth says. He and his wife, Kim, started the company with used grinding equipment in the back room of a garage. At the time, Mr. Buchenroth worked for Honda Motors, which has several plants nearby in the west-central area of Ohio. He held a number of factory positions with the firm, including production supervisor and production line engineer. This experience gave him insights into cutting tool design and the dynamics of machining processes.

This background served him and the company well as its tool regrinding and fabrication business grew. Mr. Buchenroth made it his full-time occupation in 1993. After expanding several times at its original location on family farmland, the company moved into its current, purpose-built facility, which offers 20,000 square feet of production space. Honda’s massive automotive transmission plant sprawls across several acres next to the industrial park where West Ohio is located in Russels Point.

Most of West Ohio’s main production resources consist of six high-end, multi-axis cutting tool grinders from Walter (a United Grinding company in Fredericksburg, Virginia). These machines are complemented by a Helicheck optical measuring machine and Helitronic Tool Studio software for tool design, also from Walter. Although this level of tool grinding capability is outstanding, Mr. Buchenroth says that what sets West Ohio apart is the company’s ability to develop custom tool designs for specific applications. These tool designs are engineered to help the user achieve lower cost per part. “Our expertise is in designing tools that save money by lasting longer, reducing setups and tool changes, running at faster feed rates, decreasing cycle time and holding tighter tolerances,” Mr. Buchenroth says. The high-end grinders enable the company to produce such tools, primarily in solid carbide.

In recent years, however, West Ohio has devoted more attention to expanding design and production of PCD-tipped tooling. In 2011, PCD tooling represented about 30 percent of the company’s revenue. Mr. Buchenroth expects this percentage to grow in 2012.

Grinding PCD is a challenge. PCD stands for polycrystalline diamond. Diamond is the hardest known substance. “You end up grinding PCD with a diamond grinding wheel, a process in which the amount of material removed from the workpiece and wheel is about equal,” Mr. Buchenroth explains. This makes the process very slow and expensive.

To accommodate the growing demand for PCD-tipped cutting tools, West Ohio acquired a Walter Helitronic Power Diamond machine that combines grinding and an electrical erosion process. On this machine, a disk-shaped, tungsten-copper “grinding wheel” uses electrical energy to erode material rather than remove it with abrasive contact. For some geometries, this erosion process shapes PCD materials more efficiently than grinding. However, some of the geometries required for PCD-tipped tools cannot be produced with a wheel-shaped electrode.

So in November 2010, West Ohio turned to Vollmer for the shop’s first QWD760 wire EDM, a machine specifically designed and optimized for wire cutting PCD. The speed, flexibility and capability of wire technology adapted for PCD enable the shop to produce a wider range of tool types and geometries, Mr. Buchenroth says. The wire erosion process also produces cutting edges 20 to 50 percent faster than grinding, a key factor in speeding finished custom tools to customers.

“We’re also using wire EDM to rough-cut edge profiles on brazed carbide inserts before we go to grinding,” Mr. Buchenroth says. This technique, reduces the need for grinding, thus boosting the throughput of the grinders.

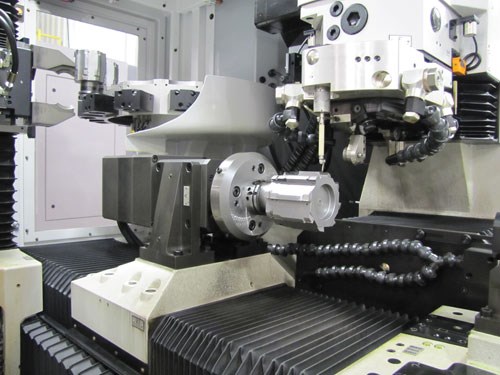

West Ohio acquired its second Vollmer wire EDM, a QWD760H, in July 2011. This machine carries the H designation because it is equipped with a robotic tool loader and unloader for lights-out operation.

Why wire EDMing PCD is PDQ

Scott Ries, PCD division manager for Vollmer America, works closely with West Ohio in its implementation of these wire EDMs. He understands the shop’s commitment to making tools that help its customers obtain a lower cost per part. However, there is a trade-off introduced with using EDM to form PCD cutting edges rather than grinding, he points out. According to Mr. Ries, grinding produces longer lasting cutting edges in PCD because the edges tend to be slightly smoother. Typical ground edges have a surface finish of Ra 0.04 µm, whereas EDMed surfaces have a finish of Ra 0.20 µm, but the difference in performance is slight compared to the higher cost and longer lead time required to grind PCD edges.

Mr. Buchenroth concurs with this assessment of the trade-off. “Our PCD-tipped cutting tools with wire-cut edges will perform about 85 to 95 percent compared to ground PCD edges,” he says. The slightly better smoothness and integrity of the ground edge surface accounts for this difference. Because wire cutting is more efficient, though, West Ohio can turn around new or retipped tools in significantly less time.

According to Mr. Ries, the Vollmer wire EDMs cut PCD efficiently and to an edge quality that is close to what grinding can achieve because of advances in the EDM generator, the circuitry that controls the impulses of electrical energy to create an effective spark. Developments in solid state technology provide a more uniform and reliable “square wave form” to the individual impulses. Although the microscopic diamond particles in PCD materials are not electrically conductive, the cobalt binder and carbide substrate are. This makes PCD EDMable.

The QWD machines are preset at the factory with cutting parameters optimized for each of the major proprietary brands of commercially available PCD stock. The conversational programming system at the CNC enables the machine operator to select appropriate settings for pre-roughing, roughing, finishing and fine finishing cuts. Wire paths are calculated automatically from imported CAD data or geometry created at the user panel. The software can also create a measurement routine for the on-machine probing system that automatically “touches off” selected surfaces to detect and compensate for discrepancies in insert orientation resulting from the manual brazing operation.

For experienced users such as West Ohio, the preset EDM parameters provide a convenient starting point. “We’ve tweaked the generator settings based on our own observations of wire cut results, and we usually achieve the required finishes in one or two passes at higher feed rates,” Mr. Buchenroth says.

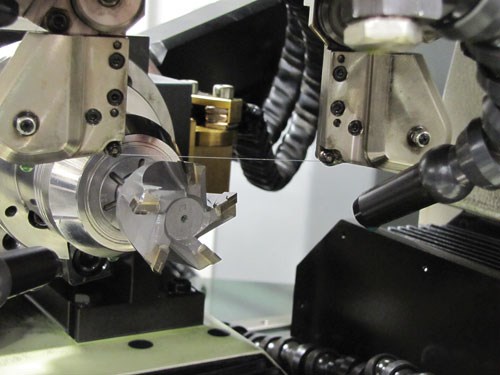

Of course, the horizontal configuration of the wire guides is also important. In this orientation, the E axis can swivel 180 degrees. Combined with the programmed rotation of the workpiece in the workholding spindle, this range of motion enables the machine to create complex profile forms. These include the edges on the internal geometry of bell-shaped tools, such as hollow milling tools with internal profiles, and inward facing cutting edges on multi-step cutters that combine drilling, reaming and countersinking capability.

Typical vertical wire EDM units with a programmable U/V axis can tilt the wire to a maximum angle of 45 degrees. This feature is handy for cutting steep tapers in large workpieces, but it imposes awkward setup demands for PCD cutting tool applications. Internal profiles cannot be accessed in this configuration. In addition to the clearance constraints, one of the difficulties when cutting with a tilted wire on a vertical EDM is maintaining adequate flushing.

On the QWD horizontal machines, repositionable jointed nozzles direct a flood of dielectric fluid to the cutting zone. These machines also use a common grade of EDM oil as the dielectric fluid rather than deionized water. The shop uses “ten thou” (0.010 inch, or 0.25 mm) diameter zinc-coated brass electrode wire for almost all PCD and carbide cutting.

Both machines at West Ohio are equipped with programmable workpiece spindles that clamp the centerline of the cutting tool parallel to the X axis. This rotary axis is designated the A axis. The machines can also be equipped with programmable tailstocks to support long cutting tool bodies. Because the bed and column of the Vollmer EDMs are made of polymer concrete, they have the rigidity to cut to an accuracy of 5 microns or better, Mr. Ries says.

To meet an anticipated surge in demand for PCD tooling, the shop opted to include an integrated loading/unloading system on the newer machine. This system includes 12 stations for tools mounted in HSK 63 holders. The robotic system enables the shop to run this machine in lights-out mode.

Trends Favoring PCD

Mr. Buchenroth believes that PCD tooling will continue to grow in importance and popularity. In the two industries that West Ohio primarily serves, automotive and aerospace, preferred workpiece materials are changing. In automotive, for example, high-silicon grades of aluminum offer a strong but lighter alternative to other materials for transmission housings, cylinder heads, suspension parts and even engine blocks. Substituting these grades of aluminum reduces vehicle weight and improves fuel mileage, an important consideration in light of recently legislated fuel efficiency mandates.

The problem is that high-silicon aluminum is a very abrasive material that inflicts excessive wear on solid carbide tooling. The higher the silicon content, the greater the wear on the cutting tool. The extreme hardness and wear resistance of PCD-tipped tooling make it a better choice, but economic issues are also a factor.

PCD-tipped cutting tools are generally six to eight times more expensive than comparable solid carbide tools, but PCD will have as much as 25 times the tool life in these materials, Mr. Buchenroth says. The production efficiencies and improved cutting edge quality associated with wire-EDMed PCD tooling is tipping the cost calculation away from solid carbide tooling. “In the recent past, the higher cost of PCD was usually only justified for aluminum grades with 14-percent silicon content. Now we are seeing PCD meeting the cost formula for 7-percent silicon grades,” Mr. Buchenroth explains. This trend supports growing acceptance of PCD tooling and means more business for West Ohio.

Aerospace presents a similar scenario. Various types of carbon-fiber composite materials are replacing aluminum aircraft components to reduce weight and fuel consumption. Most of these composite materials are very abrasive and can “chew up” carbide tooling quickly. Another issue is delamination or fraying of layered composite materials during the machining processes. Cutting tools that retain a very sharp cutting edge, such as PCD, have an advantage in these applications. Tool geometry can also influence a cutting tool’s tendency to degrade composite materials. New tool designs that minimize these unwanted effects often involve intricate geometry and cutting edge profiles that work well with PCD materials.

Mr. Buchenroth feels confident that his company is well-positioned to meet increased demand for PCD tooling. The three most important factors he cites for this confidence are having the right skills to develop effective custom tool designs, having the right manufacturing technology, such as advanced grinding and electrical erosion machines, and having the right kinds of employees to create a cohesive and dedicated workforce. “West Ohio is very fortunate to have all three of these in place. And of the three, I consider the dedicated workforce to be the most valuable,” Mr. Buchenroth concludes.

Related Content

GF Machining Solutions EDM Features Enhanced Control

The Cut F 600’s iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process, eliminating wire breakage while reducing overall wire consumption.

Read MoreDielectric Oil Dramatically Reduces EDM Maintenance

Plagued by repeated small fires that interrupted its wire EDM throughput, this cutting tool manufacturer changed its dielectric oil and both eliminated fires and reduced its oil consumption.

Read MoreSodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreMC Machinery Displays EDM, Precision Milling, 3D Printing

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More