Advanced Grinding, Plain and Simple

Advanced grinding equipment gives this shop the flexibility and automation it needs to serve customers with either rapid-response or high-volume jobs.

Share

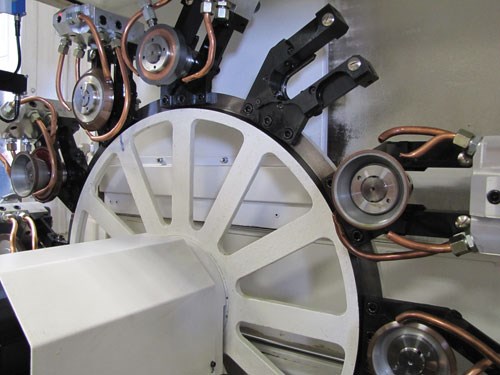

At first glance, it seems odd to see grinding wheels and coolant manifolds instead of cutting tools in the automatic “tool changer” of a CNC machine tool. Then you notice that this is a cutting tool grinding machine, a Helitronic Vision from Walter (a United Grinding company based in Fredericksburg, Virginia). The ability to change “grinding sets” as rapidly as changing end mills, taps or drills on a machining center gives this grinding machine much the same versatility and productivity associated with a vertical or horizontal machining center.

Features such as the automatic wheel changer, an on-board probing system and robotic pallet loading are essential for the shop that owns this grinder because mixing rapid-response job shop work with repeat, high-volume work is its competitive edge. These features enable fast changeover and simplified setup so that short-run jobs can be cycled through the machine efficiently. Other features enable the machine to run lights-out for economical production of high-volume repeat work.

The shop, True Cut Tool Co., is located amidst cornfields near New Carlisle, Ohio (a few miles northeast of Dayton). It is primarily a manufacturer of special cutting tools. Almost all of these tools are custom designed for specific applications in the automotive, medical, household appliance and plumbing fixture industries.

The owners of True Cut consider their chief competition to be the clock and the calendar, as opposed to other cutting tool suppliers. They are out to beat the tight turnaround times promised to customers, who are up against their own demanding production schedules and pressing delivery due dates. “We have to have advanced grinding capability to do this,” says Larry Nicodemus, True Cut founder and company vice president. He and his four sons (Kendall, Scott, Zane and Chad) form the management team. All four sons are part of the production team as well, each with a special area in which they run the machines themselves or closely supervise the employees who do. Kendall, the oldest son and now company president, has one son who works in the shop. About 17 people (family included) are employed at True Cut.

At first glance, it also seems odd to see Larry, Kendall and Scott in old-fashioned full beards. Larry’s wife, a frequent visitor to the shop, wears a bonnet and a long, plainly styled dress with a short shoulder cape. The explanation for their appearance is simple. The Nicodemus family belongs to the Old German Baptist Brethren Church. This community, which shares its roots with the Amish and Mennonite branches of the same, 400-year-old religious movement, emphasizes plainness and simplicity in lifestyle and dress so that nothing distracts them from devotion to serving the Lord as commanded in Scripture. Traditionally, ordained elders in the church wear the beards as a mark of maturity in faith and dedication to church service.

There seems to be no contradiction between the plain and simple outlook to which the Nicodemus family adheres and the way in which they manage and operate the shop. Humble, honest and honorable service to customers (and employees) is the core of the company’s business model. As Larry explains, producing high-performance, high-precision cutting tools for on-time delivery would be impossible without a commitment to advanced grinding and machining technology. It’s that simple.

This commitment to technology extends back to 1972, when Larry started the company as a tool resharpening business with strictly manual grinders and equipment. As his skill and knowledge grew, he moved the shop toward the production of specially designed cutting tools tailored to specific applications. This meant constantly updating his grinding and machining equipment, a pattern that continues to the present. Likewise, as the shop’s capability grew, so did its customer base, which has come to rely on True Cut for fast-turnaround custom tooling and high-volume production of special tools not provided by other vendors. For example, True Cut produces engraving tools for tire molds by the hundreds. These are delivered to several major tire manufacturers under blanket orders. The shop also repairs and regrinds the cutters it produces.

The shop’s Helitronic Vision CNC grinder represents its latest investment in advanced grinding technology. This five-axis CNC machine exemplifies several important observations about the way this shop succeeds. First, this machine meets the shop’s requirements for close tolerance, multi-axis grinding capability. Second, the shop takes advantage of this capability by being smart about fully utilizing its flexibility and automation. Third, the shop leverages the machine’s capability by applying it to its own innovative tool designs. The cutting tools that True Cut produces on the Vision last longer and perform better not only because they are well-made, but also because subtle design elements are based on a deep understanding of cutting processes. “Details such as land thickness or cylindrical margin thickness can make a significant difference. We know a few ‘thou’ one way or the other can mean 20 to 60 percent longer tool life for the customer,” Kendall explains.

SMART SHOP THINKING

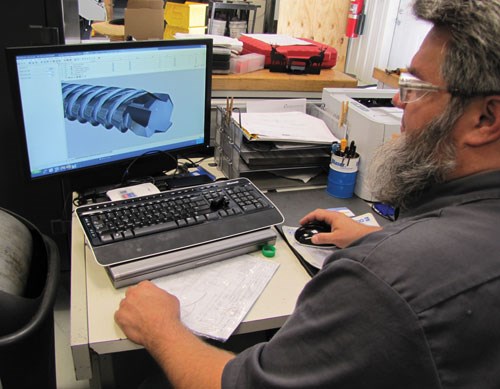

Managing operations on the Vision is the primary responsibility of Scott, the second oldest son. His work desk/programming station is located right in front of the machine. Multi-axis capability enables it to grind complex shapes and to complete most tools in a single setup. The machine’s CNC provides sufficient high-speed computational power to coordinate the simultaneous axes moves needed for intricate contours, unusual flute forms and complex geometries.

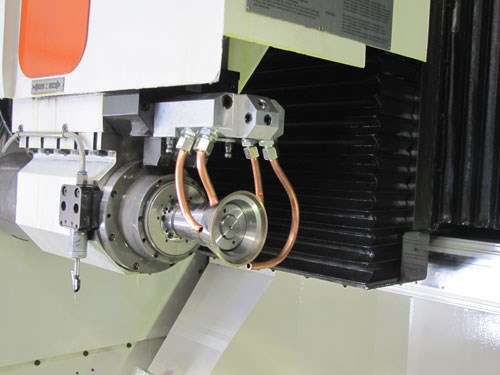

The automatic wheel changer is one of two conspicuous features on either side of the machine that are noteworthy. The wheel changer has 12 stations for grinding sets, which consist of one or two grinding wheels mounted on an arbor. Each station also holds the coolant manifold for that specific grinding set. Several copper coolant nozzles on the manifold are positioned to deliver coolant to the wheel for maximum effectiveness. The grinding wheel arbor’s HSK-50 interface mates with the grinding spindle. Self-sealing, spring-loaded hydraulic connections on the coolant manifold lock into coolant ports on the face of the spindle as the arbor enters the spindle bore. Grind-to-grind time for a wheel change is about 15 seconds.

“Whenever possible, we mount two different grinding wheels on the arbor. This adds to the capacity of the tool changer and often enables us to skip a wheel change. The CNC program simply repositions the second wheel for additional operations,” Scott says. This is a good example of how smart thinking gets more out of a machine feature for added productivity. Another example is Scott’s approach to managing the grinding sets. He stores as many arbors mounted with wheels and manifolds as the shop will allow him to order.

The current total is close to 350. “I keep completed sets in a cabinet at the machine. This means I almost always have a preassembled grinding set that I can swap into the wheel changer for certain jobs or operations when they come up,” he explains. Such tactics keep setup time very low, one of the keys to running many one- and two-piece jobs across this machine efficiently.

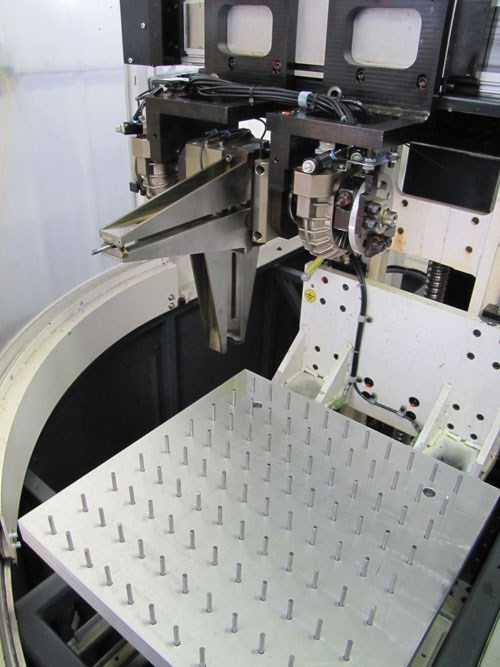

More examples of smart shop thinking come up when discussing the other conspicuous feature, the autoloader on the other side of the machine. The autoloader accommodates four 200-mm pallets that can be presented sequentially to a robotic device that loads the workpiece spindle automatically. Here again, homegrown ingenuity enhances this automation. For example, Scott has designed pallets that hold 100 to 110 carbide blanks for the engraving tools the shop provides to tire mold manufacturers and other companies that engrave molds or embossing dies. The pallets were produced in the shop to his specs.

As orders for these tools are received, he loads the pallets and stocks the loader during the day for unattended processing overnight. As long as the pallets hold blanks of the same shank size, different configurations of engravers can be processed together (the corresponding toolpath programs are coordinated by the CNC). Batches with more than one shank size require manually changing the collet in the workpiece spindle, which Scott will sometimes do after hours to resume unattended operation.

NOT AN ISLAND

Two more important points must be made about the Vision grinder. For one, the machine is part of a “package” that includes an automatic inspection system and special cutting tool design software. For another, like all of True Cut’s grinding machines, the Vision benefits from CNC turning and milling operations that are carefully engineered to get the most out of grinding capability.

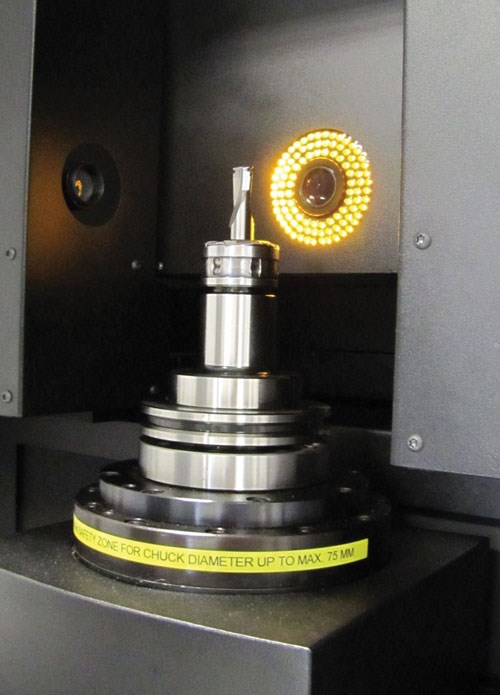

True Cut acquired the Vision grinder along with a Walter Helicheck in a special offer from the builder. The Helicheck is an optical inspection and measurement machine that measures tool diameters as small as 0.004 inch (0.1 mm) and edge radii as small as 0.0002 inch (5 micron). “We first considered the Helicheck because we thought it would be a useful option, but now we see it as an essential complement to the grinder,” Larry says.

It is especially valuable in speeding setups on short-run work because precise tool blank dimensions can be measured and downloaded to the Vision’s CNC via a fiber optic cable for offsets to the CNC program. Grinding wheels are also inspected on this machine to verify dimensional accuracy and identify high or low spots. This data is downloaded automatically as well. Of course, finished tools are routinely inspected on this machine, but mainly for the documentation required by some customers.

Although acquired separately a short time later, the tool design software is also an essential part of the integrated Vision package as installed at True Cut. The software, called Helitronic Tool Studio, enables Scott to review and tweak cutter designs before generating the complex grinding paths for the Vision and transmitting them to the CNC. His workstation is right next to the machine, so there is virtually no lag between his offline programming efforts and grinding results. This software includes features of special interest to cutting tool designers. For example, the shape, angle and orientation of spiral flutes can be easily manipulated and displayed as a 3D solid. Such software design tools are critical.

Kendall, who is True Cut’s chief tool design engineer, agrees. “They let us capture the cutter designs that we come up with to solve customer problems,” he says. He does the initial design work in Autocad Inventor, which enables him to create a 3D solid model that can be imported into Tool Studio. “We design a lot of stepped tools, such as drills and reamers, that combine otherwise separate operations. We know how to blend clearance angles and cutting edges, add the right back tapers and apply superfine finishes where needed to make a long-lasting, time-saving tool. We couldn’t produce these tools efficiently if we couldn’t do the CAD and CAM work effectively”

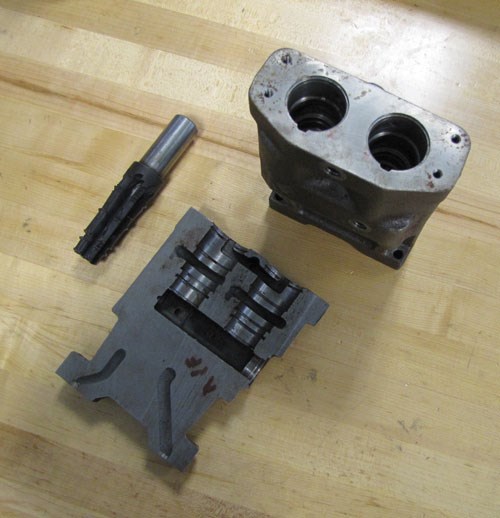

Likewise, CNC turning and milling go hand in hand as critical supporting technologies for advanced grinding capability. CNC machining is the domain of sons Chad and Zane, who run a CNC lathe and a CNC mill respectively. These machines are housed in a separate building immediately behind the main facility, where the grinders are located. Both gentlemen intuitively understand that the turning and milling tasks they do are primarily pre-grinding operations.

These machines are largely used to rough-cut HSS blanks. “How well we prepare the blanks makes a difference in the efficiency of our grinding operations and ultimately in the quality of the finished cutting tool,” Chad notes. For example, blanks must be turned precisely on center to deliver even stock conditions for the grinders. Zane’s milling operations are likewise aligned to enhance grinding results. For example, he programs the milling of flute forms so that they provide strong support for the carbide or CBN segments that will be brazed in place before the final grind. “I don’t want any excess overhang of the segment that might weaken the edges,” he explains. He adds that the exact values he enters vary from design feature to design feature and are based on experience with tool performance in the field. It’s as much art as science.

TRUE STRENGTH

It is a testament to the effectiveness of True Cut’s approach that any one of the Nicodemus family members can cite an emergency rush job in which the shop was able to design, produce and deliver a special cutter in a matter of days, or even overnight.

As remarkable as these heroic efforts might be, they shouldn’t obscure the truest indicator of the shop’s core strength. That is, the shop’s ability to analyze a customer’s part and design a cutting tool that solves a particular problem, or, as is often the case, several problems at once. An example might be a stepped tool that drills, countersinks and chamfers in one operation and produces all these features to a tight tolerance and fine surface finish. The design must also provide long life and allow multiple regrinds. Kendall considers these the most satisfying challenges. “We can get a sample tool or two to the customer in a few days. While they begin production, we can check results, find some new improvements and get a better version back to the customer a few days later,” he says.

These complex tools are prime candidates for production on the Vision grinder. “We’ve learned to use blade-like superabrasive wheels that can be maneuvered in five axes to get blends and clearances that would be impossible to produce otherwise. This frees up our ability to be imaginative and creative in tool design,” Kendall says.

IN BUT NOT OF THIS WORLD

The intensity of focus that True Cut brings to producing cutting tools is remarkable. It is not, however, obsessive or consuming. Larry, like a good patriarch, is watchful that duty to family, church and community are not pushed aside in the name of business. He is strict about keeping the shop closed on Sundays. Respectful behavior in the shop is enforced at all times, but with a gentle hand.

Fond of quoting Scripture, Larry cites Chapter 17 in John’s Gospel, in which Jesus makes the distinction between being in the world and being of the world. As Larry and his family see things in light of this teaching, the shop is in the world, so they seek to conduct their business as Jesus conducted his in this world—that is, at the service of others. Their business model (and its commitment to technology) is in keeping with this ideal. Yet, as Jesus proclaimed of his followers, they are not of this world but belong instead to a kingdom that is apart from it. For the family, this apartness is simply expressed and plainly affirmed by simple living and modest dress. It is their witness to grace.

Related Content

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)