Between Centers And Centerless Grinding In One Setup

It sounds like a contradiction in terms-between centers and centerless grinding on one machine. But for some categories of workpieces, it's a viable production process that can yield machining time reductions of 45 percent over separate grinding operations.

Share

It sounds like a contradiction in terms—between centers and centerless grinding on one machine. But for some categories of workpieces, it's a viable production process that can yield machining time reductions of 45 percent over separate grinding operations.

In general, OD grinding is performed either between centers or on a centerless grinding machine. When the features of the workpiece, such as crankshafts, camshafts, armatures or gear shafts require both grinding operations, they are usually done sequentially on purpose-built machine tools.

Primarily a shop uses these grinding operations because of specific strengths inherent in each. For between center work, a workpiece that has a critical concentric feature such as a cam lobe or gear or crank pin is processed between centers because the relative positions to the shaft diameter can be maintained.

Centerless grinding, on the other hand, is best applied for creating roundness. The process is self-correcting for most out of round conditions. It is limited, however, in its ability to maintain concentricity between the shaft diameter and a lobe, gear or pin.

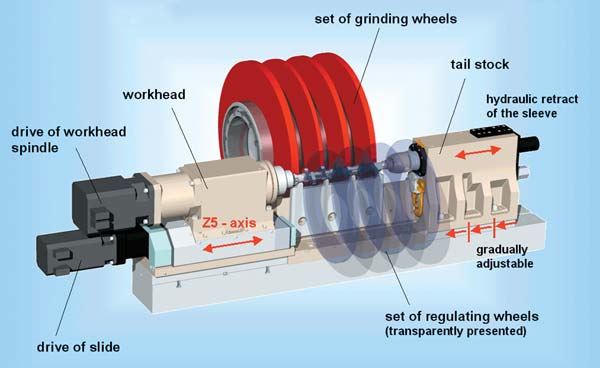

All across metalworking, shops are combining what were once independent production steps into single setup, multi-process operations that can machine a workpiece complete from a blank. In the case of the Kronos L dual from Shaudt, Mikrosa, BWF, two traditionally distinct OD grinding operations are combined on a single machine tool frame. It's basically a centerless grinder that can perform between center OD grinding.

In order to achieve a "2-in-1" process, a workhead and tailstock are installed at either end of the centerless grinder workrest blade. The workhead is equipped with a driver and programmable rotational speed.

Both workhead and tailstock centers are retractable and adjustable to the workpiece length and diameter. A recirculating ball spindle, programmable from the CNC, can position the work spindle axially. On the tailstock side, its center support (MT 4) is arranged with a sleeve that is hydraulically actuated.

In operation, the grinding wheel and regulating wheels are moved back for loading clearance. Once loaded, the shaft is clamped between centers. The wheel head slowly brings the workpiece up to its programmed rotational speed.

Next the grinding wheel is infed to the workpiece. In this operation the regulating wheel is not involved. The workpiece is ground between centers. This step grinds the desired diameters of the workpiece concentric with the centers at a cutting rate from 0.05 mm/min. to 0.10 mm/min. (0.002 ipm to 0.004 ipm).

Following sparkout, the grinding wheel retracts, and the regulating wheel is infed. It forms a prism relative to the workrest blade. With the regulating wheel in position, the work driver and tailstock retract, causing the workpiece to contact the workrest blade.

The Kronos is now in centerless grinding mode. The grinding wheel feeds in, and the workpiece is finish ground using the centerless method. When size is achieved, the wheels retract, the workpiece is unloaded and the process begins again.

For workpieces with features that are concentrically critical yet need the roundness tolerances that centerless grinders provide, this "2-in-1" process can save production time and cost.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More