How Advanced Grinding Technology Leverages Capabilities Beyond Grinding

United Grinding shows how rethinking traditional grinding technology and combining manufacturing processes can extend the role of grinding and make grinding machines more productive.

Share

“People think conventionally,” says Phil Wiss, regional sales manager at United Grinding North America Inc. When it comes to removing material from a workpiece, he says manufacturers generally find it easiest to associate particular machining operations with specific machine types. But what if a machine could do more?

To be sure, multitasking machines are nothing new — they’ve been around for years. For the most part, these machines combine similar chip-making manufacturing processes. Likewise, combined-process machines, machines in which dissimilar processes are combined, are not a new concept either, but new combinations of processes are still emerging as companies develop and fine-tune complementary technology.

A recent visit to United Grinding’s facility in Miamisburg, Ohio, provided a chance to see just how far combining processes can go in improving the effectiveness of machining and even transforming the role the machine tool might play. United Grinding North America Inc. represents eight brands of CNC grinding machines: Studer, Schaudt, Mikrosa, Mägerle, Blohm, Jung, Walter and Ewag. It serves makers of high-value components in aerospace, automotive, medical and defense, as well as makers of cutting tools. Its equipment consists entirely of grinding machines, yet some of these machines do even more. In these cases, a grinding machine that can do more becomes much more capable machine.

Rethinking Small Component Manufacturing

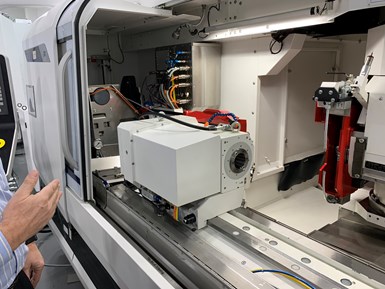

Under the Mägerle brand, United Grinding offers the MFP-30 five-axis grinding center, which is a combined-process machine designed to grind complex geometries, particularly those of small blades and vanes or heat shields for aviation turbines.

It’s still a grinding machine at its heart.

In particular, Wiss says small component manufacturers stand to see large benefits from this machine. Its ability to perform grinding operations as well as milling and drilling in a single clamping can lead to improved accuracy and faster cycle times compared to multiple setups on stand-alone machines. However, Wiss is quick to point out that it is still a grinding machine at its heart.

Phil Wiss discusses the MFP-30 combined-process grinding, milling and drilling machine. He says it is well suited for manufacturing small aerospace components.

“Manufacturers should abide by the ‘80/20’ rule when using a multi-process grinder,” he says. “This means that 80% of the time it should be used for grinding operations while the other 20% can be used for milling or drilling operations.” He says that manufacturers seeking to use a multi-process grinder for a higher percentage of milling and drilling work would be better off to buy more economical stand-alone machines than this high-precision grinder.

The machine’s direct-drive, 12,000-rpm spindle enables grinding with cubic boron nitride (CBN) wheels as well as creep-feed grinding with aluminum oxide wheels. “Creep-feed grinding is a process that can deliver more than you realize,” Wiss says. With creep-feed grinding, manufacturers can take larger depths of cut than they can with traditional surface grinding. Even added to a slow traverse rate, the material removal rate (MRR) that can be achieved is much higher than that of finish grinding. The ability to use grinding in place of a chip-making process is another way manufacturers can rethink small component manufacturing, especially when cutting harder materials commonly used in aerospace applications. In these materials, advances to grinding wheels have enabled creep-feed grinding’s MRR to increase. Finally, creep-feed grinding becomes an even more accessible option for making a part when manufacturers also have the chance to use a chip-cutting tool for operations like the precision drilling the part in a single clamping cycle.

Rethinking Tool Grinding

Another highlighted multi-process machine from United Grinding shows how rethinking tool grinding can open new channels for growth without manufacturers straying too far from their comfort zone. This machine is the Walter Helitronic Power Diamond 400. It combines rotary eroding of polycrystalline diamond (PCD) and cubic born nitride (CBN) tools with grinding of carbide and high speed steel (HSS) tools.

The Walter Helitronic Power Diamond 400 combines rotary eroding with grinding, enabling manufacturers to produce PCD tooling in a single clamping cycle. Simon Manns explains that it can be used by both new and established manufacturers in the PCD market.

According to Simon Manns, general manager of the Tool Division, this machine can provide great benefit to manufacturers that are entering into PCD tooling production. “This machine allows these manufacturers to grind carbide tools until they can break into the PCD market — it’s an entry-level way to get into PCD tooling production,” he says.

Traditionally, PCD tooling is cut using EDM equipment followed by a grinding operation to expose the diamond along the tool’s cutting edge. Manufacturers already competing in this market typically have stand-alone equipment and processes in place. That said, Manns points out that the benefits of a single machine that combines EDM and grinding processes are not limited to manufacturers just breaking into the PCD market. “It’s also very useful for manufacturers that want to improve their process,” he says, because combining operations in one machine can lead to tighter process control.

According to United Grinding, a rotary eroding and grinding machine is an economic investment for both the production and resharpening of PCD/CBN tools because complete machining of complex geometries can be accomplished in a single clamping.

The machine’s Fine Pulse Technology enables efficiency in the erosion or EDM processing. It is designed to improve surface quality, cutting edge roughness and process reliability of PCD tools. The crux of this technology is a liquid-cooled generator that offers different preset codes for different materials and surface finishes. The different codes can adjust the frequency of the pulse and the size of the current. For example, rather than spending a lot of time running a superfine cycle, Manns says that manufacturers can run a roughing cycle, followed by a semi-roughing cycle and then a superfine cycle to reduce the overall cycle time while achieving outstanding surface finishes.

Rethinking Wire Dressing

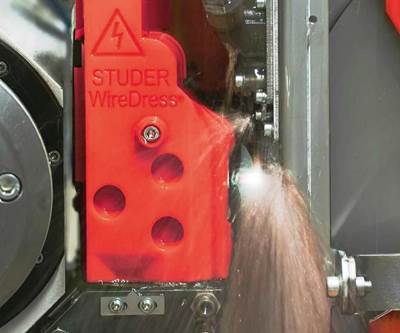

The reduced size of the second generation WireDress helps it fit into the machine more easily. It is basically split in two, with the wire cutting assembly located behind the tailstock.

A third machine that United Grinding showcased is the Studer S41 universal cylindrical grinding machine. Though the machine itself strictly performs grinding operations, it deserves inclusion here because of a different mode of combining processes: Wheel dressing on this machine — essentially, machining the metal-bonded wheel that will machine the part — is performed through either a traditional dresser or EDM. The showcased grinding machine was equipped with second-generation WireDress EDM technology, which can swivel the wire guide to cover both sides of the grinding wheel, and move to dress the wheel into precise profiles. United Grinding says it can be used to dress diamond or CBN wheels, cutting cycle times by 55%. The EDM technology erodes the bond, not the grit that cuts, so the grit is exposed and sharp. This enables the wheel to last longer and cut faster. The universal cylindrical grinding machine is used for high-production applications and can combine standard and high-speed grinding, so while this one machine performs solely ID/OD grinding, combining processes within the machine nevertheless improves and extends its capability.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreSwiss Grinding Technology in Motion

During a recent open house at Studer’s headquarters in Switzerland, the company highlighted advances in cylindrical grinding technology including automation solutions to enable long stretches of unattended operation.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)