Blade Grinding’s Need For Speed

A grinding technique akin to high speed machining offers an alternate method for grinding nickel-alloy blades and vanes used in turbine engines.

Share

The properties that enable nickel-alloy blades to perform effectively in the hot section of turbine engines also make the blades challenging to machine. Larry Marchand, an aerospace accounts manager for United Grinding who has 22 years of industry experience in the manufacture of turbine engines, explains why this is the case.

One reason nickel alloys are commonly used for aircraft and power-generating turbine engines is because heat transfer through these materials is very slow. Although the contoured airfoil section of a blade encounters high-temperature combustion gasses, the blade’s root must remain cool to avoid softening at the point of attachment with the rotor. Slow heat transfer prevents the excessive heat from progressing from the airfoil to the root.

These nickel-alloy blades are commonly produced from investment castings that are then ground to final shape via creep-feed grinding. According to Mr. Marchand, care must be taken when grinding the blades to minimize the amount of heat that is delivered into the workpiece. Because grinding heat won’t dissipate throughout the entire nickel-alloy blade, it will remain localized at the blade’s surface. This can cause the material to melt and re-solidify as a recast layer that may measure 0.001 to 0.002 inch thick. The recasting of the material can change the alloy’s physical properties, causing the blade to become more brittle, softer or harder. Blade performance and longevity could suffer.

Some years ago, a European consortium—AGNETA—set out to develop an alternate method for grinding turbine blades and vane segments made from nickel alloys and other materials such as titanium aluminides. This consortium was comprised of grinding equipment companies and turbine engine manufacturers. Testing was performed at Germany’s RWTH Aachen University. The result was a grinding method that is similar in concept to high speed machining, as well as a profile grinding machine design from Blohm that uses linear motor drives to enable rapid workpiece positioning.

Move Quickly, Grind Lightly

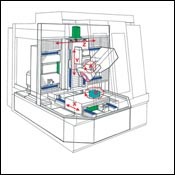

This new grinding concept was coined “speed-stroke grinding.” Analogous to high speed machining, the technique takes light, fast passes with the grinding wheel so that any heat generated during the operation will be expelled with the chips rather than into the surface of the blade. The concept required a new grinding machine that would allow extremely fast workpiece movement. The machine, called Prokos, was developed by Blohm and introduced to the U.S. market at IMTS 2006. Blohm is one of eight companies that are part of United Grinding, located in Miamisburg, Ohio.

The Prokos machine uses linear motor drives to move its aluminum worktable along the X and Z axes. The linear drives allow the table to move at 4,700 ipm in X and 2,000 ipm in Z. The table has an integral 200-rpm rotary torque motor that enables B-axis workpiece rotation. Simultaneous rapid movement of the worktable and rotary table allows the grinding wheel, which is brought to proper position in the A axis, to follow the curved profile of a blade or vane. Compared with creep-feed grinding processes, speed-stroke grinding using CBN wheels removes material 30 percent faster and provides 20 percent longer wheel life, according to the company.

The machine’s table accepts workpieces as large as 11.8 inches (L × W × H) and as heavy as 40 pounds, which is sufficient to process most blades and vane segments. To reduce the amount of moving mass on the table, the machine’s diamond-disk dressing systems are mounted directly on the machine bed on either side of the table. The vertical Y axis uses linear guideways and is driven via ballscrew. To minimize machine vibration, the machine base and cross-slide are made of the company’s proprietary polymer concrete casting material.

The spindle, which has an HSK interface, is rated at 40 hp and has a maximum speed of 12,000 rpm. It can be rotated 110 degrees in the A axis to position the wheel relative to the workpiece or dressing systems. Aircraft blades often require removal of 0.06 to 0.2 inch of material, while power generation blades may require 0.2 to 0.5 inch to be removed. In a typical scenario, the wheel is first dressed, and then roughing passes are taken to approximately 0.005 inch of the blade’s final size. The same wheel is then dressed again before taking the finishing passes.

In terms of process control, Mr. Marchand says speed-stroke grinding tends to be more forgiving than a traditional creep-feed grinding operation. Effective creep-feed grinding requires tight control of speeds, feeds, coolant pressure and application, coolant nozzle shape and so on. If any of these elements fall out of that tight control band (say a coolant nozzle gets bumped or coolant concentration levels are too low), problems can quickly develop as heat is generated at the workpiece surface. Because heat is delivered away from the workpiece with the chips, the process control band for speed-stroke grinding is more open. Speed-stroke grinding is also said to use a fraction of the amount of coolant that would typically be required for creep-feed grinding.

In addition to providing heat removal with the chips, speed-stroke grinding’s light passes lower grinding wheel pressure on the blade. This reduces the chance that the blade’s airfoil will deflect or material compression will occur at a microscopic level during grinding.

Although blades and vanes have contoured surfaces, programming such grinding operations is not as complicated as creating five-axis machining tool paths, for example. Grinding operations generally call for motion that’s either straight (to produce grooves in a blade’s root) or convex or concave (to match an airfoil’s profile). Macros have been created for the Prokos machine to simplify the programming for these components. A programmer inputs process information as prompted by the machine’s software, including geometry, workpiece size and wheel diameter (This can be done at the machine or off-line). The software then automatically generates the grinding program. The Prokos machine is currently offered with a Siemens 840D control, but a Fanuc 18i is said to be available soon.

Some blades may require a small amount of milling, drilling or chamfering in addition to grinding. The Prokos machine has a 24-station ATC that’s available to allow complete machining of blades in one set-up. The toolchanger also allows multiple grinding wheels to be stored.

Related Content

Increasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreShop Tour Video: From Garage Shop to Leading Aerospace Supplier

From repairing aircraft interiors to manufacturing medical implants, Superior Joining Technologies excels at CNC machining, TIG welding, laser welding, and NADCAP-accredited nondestructive testing. Discover how this Rockford-based company supports the aerospace industry through a combination of advanced technologies.

Read MoreGrob Announces Aerospace Technology Event

At the Aerospace Technology Day event — which takes place at Grob’s facility in Bluffton, Ohio, on November 19th, 2024 — attendees will see five-axis aerospace parts machined live, be able to consult with a panel of technical experts and more.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More