When Grinding Is Like Turning

This shop leverages a high-speed peel-grinding process that resembles turning to effectively grind challenging materials such as carbide. Inherently low grinding forces mean high material-removal rates are possible.

Share

High-speed machining using CNC milling machines is a process in which a cutting tool takes fast, light cuts at high spindle speeds to realize higher material-removal rates compared to slower hogging operations. Similarly, the goal with peel grinding is to achieve high material-removal rates for cylindrical parts requiring outside-diameter (OD) grinding. However, this high-speed grinding process differs from its milling counterpart in that while the operation uses fast grinding wheel speed, it also takes relatively deep passes. It is able to do this because the wheel is very thin and the grinding forces imparted into the workpiece are very low compared to plunge grinding with a wider wheel, especially when grinding wheel peripheral speeds are in the 80 to 180 m/sec. range (40 to 50 m/sec. are common with typical cylindrical grinding operations).

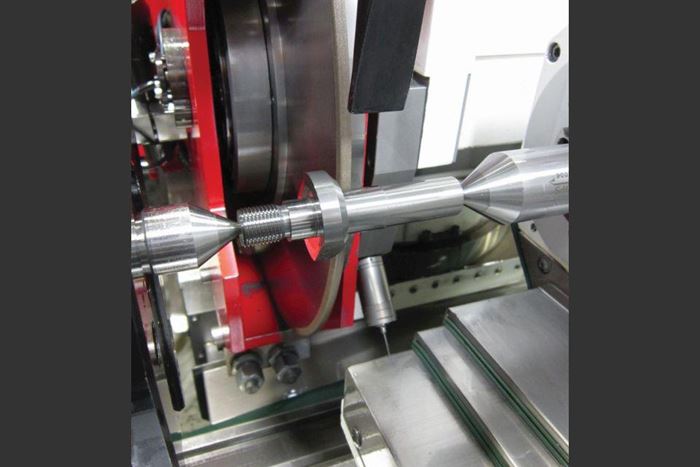

In fact, peel-grinding operations resemble single-point turning on a lathe, because, similarly to a lathe tool’s, the grinding wheel moves in the X and Z axes to grind contours, different diameters and other features on a workpiece. When combined with proper grinding wheel technology and high-pressure straight-oil coolant delivery, the very high speeds enable improved material-removal rates for challenging materials such as carbide, ceramic, polycrystalline diamond and even glass.

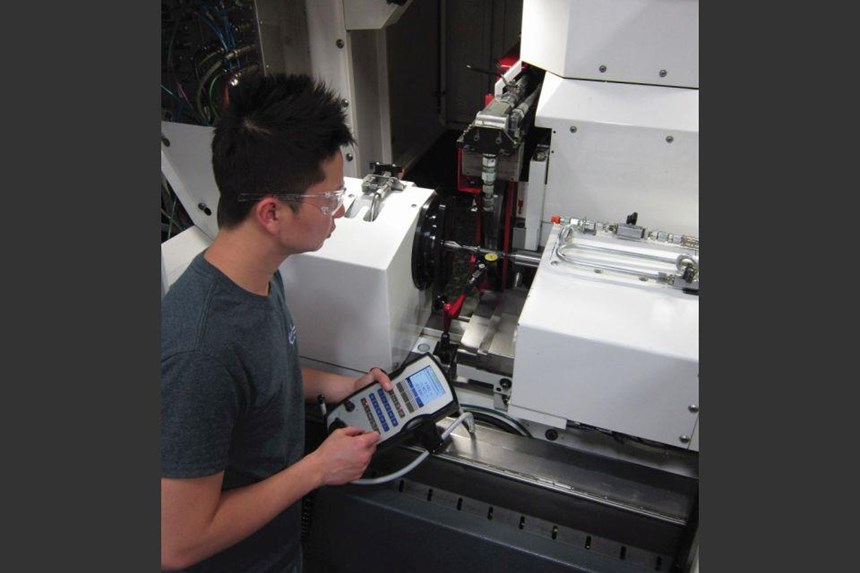

In the case of Complete Grinding Solutions, high-speed peel grinding extends the flexibility of one of its already inherently flexible universal CNC grinding machines, as I learned during a recent visit to the Springboro, Ohio, grinding shop’s new facility.

Peel Grinding’s Appeal

Beat Maurer, company president, launched Complete Grinding Solutions in 2005 with partner and Vice President Raphael Obrecht. Prior to that, Mr. Maurer worked for Swiss grinding machine OEM Studer in Switzerland for 25 years, starting as an apprentice and eventually earning an engineering degree specializing in grinding technology. He then moved to the United States, where he worked for the company for an additional 16 years prior to starting Complete Grinding Solutions with Mr. Obrecht, who also had worked for Studer.

In 2013, the company moved a short distance away from its original Springboro location to a new 9,600 square-foot temperature-controlled facility. The shop has seven grinding machines from Studer (represented in the United States by UNITED GRINDING, located in nearby Miamisburg) and can perform ID/OD grinding, internal grinding of complex shapes, thread grinding and out-of-round grinding. Because it is a job shop, the company performs a wide range of grinding work in small batches for customers in numerous industries, including aerospace, automotive, computer, medical, oil/mining, plastic injection molding, renewable energy, and tool and die.

The 12-person shop focuses on highly challenging, tight-toleranced grinding work (it offers consulting and product development services, too). For example, it can ID-grind aftermarket diesel fuel injector nozzle bodies to ±20 millionths of an inch concentricity, a tolerance Mr. Maurer says typically is achieved only after honing. In addition, Complete Grinding Solutions specializes in grinding exotic materials, which is how it benefits most from its proven peel-grinding process. One example is custom carbide arbors for ID grinding tools that the company manufactures for grinding-tool OEMs. Mr. Maurer points out that carbide is roughly 10 times more rigid than hardened steel, which makes the material well-suited for this type of grinding tool, because it enables aggressive feed rates without arbor deflection. In addition, tool life is long because carbide is very wear-resistant. Mr. Maurer says peel grinding the outer diameter of carbide arbor takes just a few minutes compared to approximately 20 minutes using conventional, lower speed grinding processes.

The machine the shop uses for high-speed peel grinding is a Studer S41 universal cylindrical grinder. Mr. Maurer says this machine can perform a variety of operations, including ID, OD, cam, thread and out-of-round thread grinding. It also offers sufficient rigidity and features design elements that make it well-suited to perform high-speed peel grinding, including a Granitan S103 mineral-cast machine bed, which is said to offer better vibration damping and more stable thermal characteristics than conventional cast iron beds.

In addition, the S41’s StuderGuide guideway system has longitudinal and cross-slides that are made of gray cast iron and molded directly into the machine base. They feature ground surfaces finished with a wear-resistant Granitan S200 material to enable high load capacity and provide additional vibration-damping qualities. The slides are powered by linear motors having direct measuring systems with a resolution of 10 nanometers.

Mr. Maurer says that when this machine is set up for peel grinding, it can achieve material-removal rates upwards of 50 mm3/sec./sec., whereas conventional, lower speed cylindrical grinding processes commonly achieve material-removal rates ranging from 2.5 to 5 mm3/sec./sec.

Peel grinding differs from plunge grinding with a wide, profiled wheel. As with turning using a single-point tool, peel grinding maneuvers a thin wheel in X and Z axes to completely grind the profile of a part. Therefore, a single wheel can grind a variety of diameters, contours and other features. Programming isn’t terribly daunting, either. Mr. Maurer says point-to-point programming can be performed at the machine for basic profiles, while StuderWin Contour software can be used for more complex geometries.

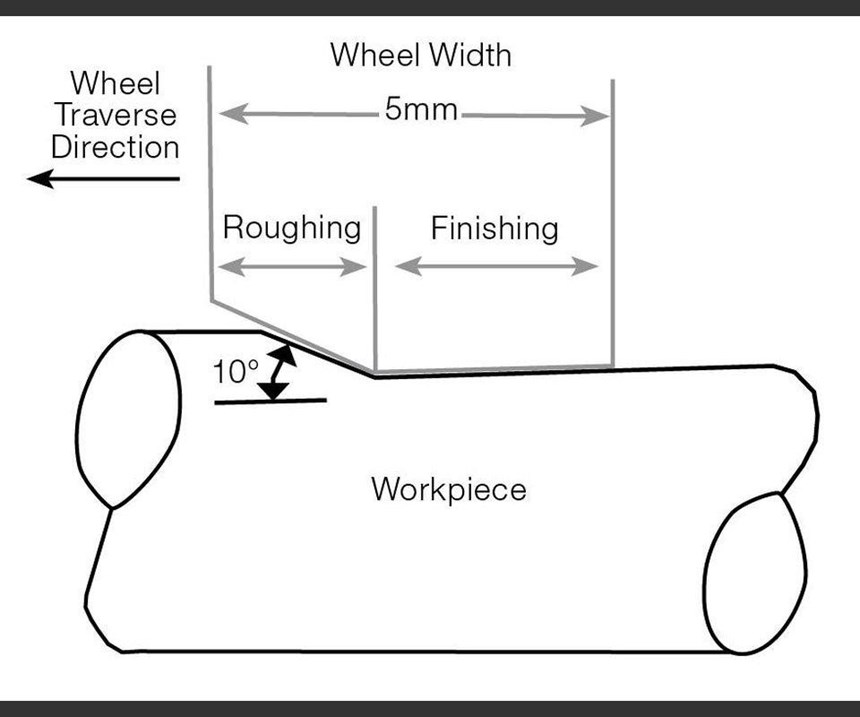

In most cases, there is no roughing pass followed by a finishing pass. Typically, one heavy cut takes care of all necessary material removal while leaving behind a quality surface finish. Looking at the wheel profile drawing in the slideshow above shows why. These wheels are typically 5-mm wide and 400 mm in diameter. The face of the wheel has a 10-degree lead angle where roughing/material removal is performed followed by a flat profile that provides a quality ground finish. Therefore, one pass of the wheel performs both roughing and finish-grinding. Most wheel wear occurs at the corner where those two areas transition, meaning the wear rate is essentially the same whether shallow or deep grinding passes are made. The shop primarily uses metal bond wheels from Tesch, located in Germany.

A small area of contact means both tangential and normal grinding forces are low. In addition, as wheel speed increases, both of these forces decrease exponentially. For example, when running at a peripheral wheel speed of 35 m/sec. with a material-removal rate of 1.0 mm3/mm, the tangential force would be 1 N/mm. On the other hand, running the wheel at 100 mm3/mm and the same material removal rate would result in a tangential force of only 0.2 N/mm.

Low grinding forces mean that long, relatively small-diameter workpieces might not require a steady rest for added support during peel grinding. Plus, the heat created during peel grinding is evacuated with the chips, which prevents workpieces from burning and also facilitates faster grinding speeds.

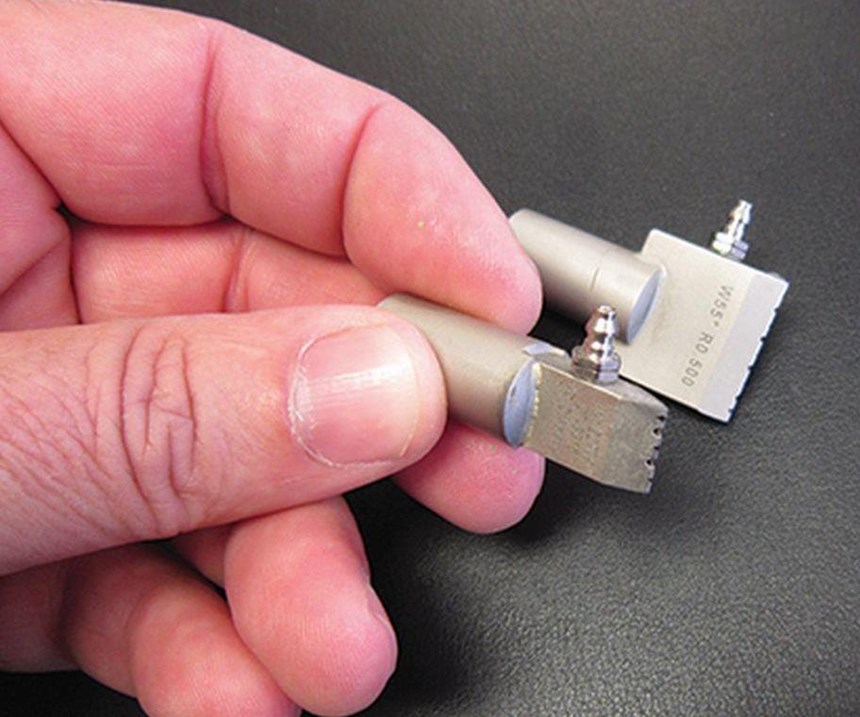

Mr. Maurer says peel grinding’s reduced grinding forces mean wheels require dressing less frequently. Wheels used for peel grinding carbide typically require dressing after 500 to 1,000 parts. That’s good, because dressing metal bond wheels even using the S41’s silicon carbide rotary dressing disc can take upwards of a day.

That said, proper coolant selection and delivery is also important for effective high-speed peel grinding. Complete Grinding Solutions uses straight oil for coolant. Mr. Maurer says this is necessary to provide sufficient lubrication at a grinding wheel’s cutting edges, which isn’t attainable with oil/water emulsions. In addition, peel grinding requires coolant delivery at high pressure to ensure that the coolant gets to the area of contact between the wheel and workpiece. Although a grinding machine with a conventional low-pressure system might provide 5-bar (72.5-psi) pressure and have a 100-gallon tank, the S41 for high-speed peel grinding offers 50-bar (725-psi) pressure and has a 500-gallon tank.

Because straight oil is used as the coolant, the S41 has an integral fire detection and suppression system. Were a fire to start, rubber tubing routed inside the machine would rupture, triggering a valve to deliver a high volume of carbon dioxide through multiple diffuser nozzles inside the workzone to extinguish it.

Small Shop, Big Technology

Mr. Maurer says it is rare for a shop of Complete Grinding Solutions’ size to have this type of high-speed peel-grinding process. He admits it represents a significant investment, but justifies it knowing it offers the company a competitive advantage to enable the shop to take on complex work that others can’t. This shop’s story is similar to others profiled in this magazine in that it has made the decision to adopt advanced machining technology and processes to take on the type of challenging work that serves to set itself apart from its competition.

###

Related Content

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)