Share

Fritz Studer AG’s Thun, Switzerland headquarters was the site of its annual Motion Meeting on February 10, 2023. The theme of this year’s event was “Expedition 2023.”

Fritz Studer AG, a United Grinding company, held its annual Motion Meeting on February 10, 2023, at its Thun, Switzerland headquarters. The event revolved around the theme of “Expedition 2023.” This was fitting, as an expedition’s success is oftentimes determined by the team’s preparation, and Studer’s products aim to ready manufacturers for potential uncharted waters in 2023 and beyond.

The press conference included an overview of Studer’s 2022 performance. It was the company’s third-best year for order intake, said CSO Sandro Bottazzo. Stability in the majority of the company’s end markets (tooling, die/mold, machine manufacturing and precision engineering) offset a downturn in the automotive sector. Studer handled the year’s supply chain difficulties through building strong partnerships with suppliers, using a risk management approach by dual or multi-sourcing, and coordinating its engineering and purchasing departments. Its in-house vocational training program (trainees account for more than 11% of the company’s workforce) and plans to continuously update its facilities (spindle and shaft manufacturing are scheduled to be updated in 2023, and warehousing and transportation will be revamped by 2025) are helping it deal with the ongoing labor shortage, as having updated facilities can attract and retain employees.

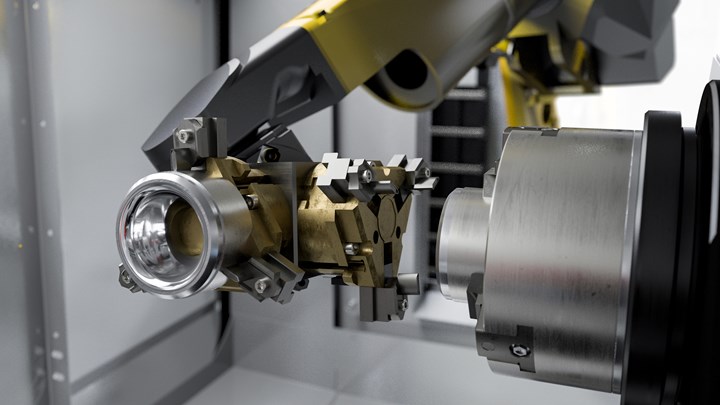

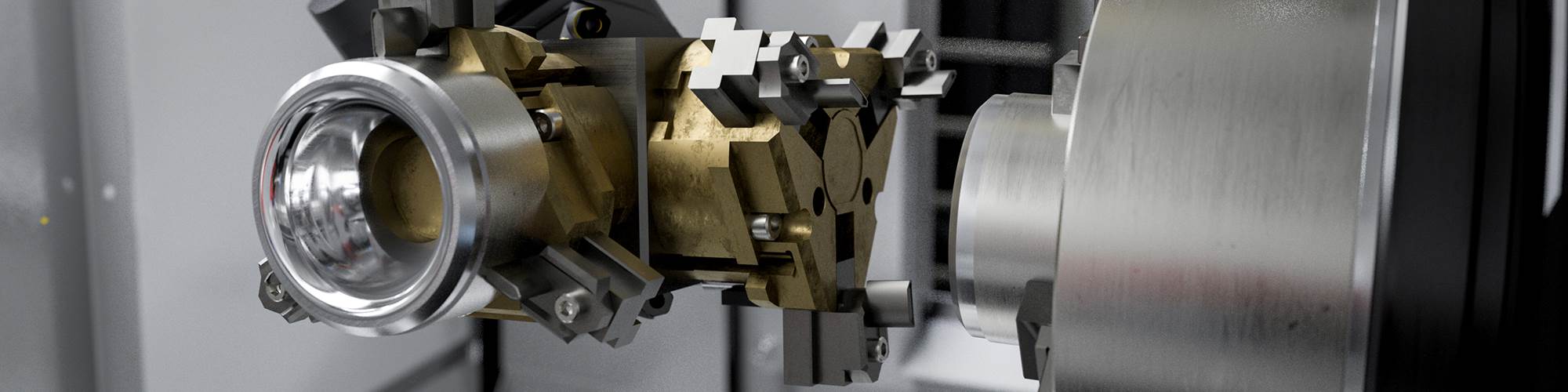

Studer’s roboLoad is a robotic automation system for its S121, S131 and S141 grinding machines. Users can set it up without programming knowledge and gain unattended machining time over extended breaks and night shifts. Photo Credit: Fritz Studer AG

Studer’s products also aim to help users prepare for a range of business conditions. The event placed a particular focus on automation systems that can help users implement unattended machining on its grinding machines.

The easyLoad, compatible with the S31, S33, S22, and S41 grinding machines, uses an adjustable conveyor to automate production of a maximum of 50 workpieces ranging to 300 mm with a length of 30 mm and diameter of 50 mm, giving manufacturers a half-hour or more of unattended production. For S22 users who produce higher volumes of parts, the company offers the ecoLoad, which uses either a carousel magazine or a prisma loader with a V-gripper. For higher-volume production, the uniLoad docks to S31 and S33 machines and uses a prismatic conveyor and rack to provide roughly an hour of unattended production. The smartLoad, with its compact conveyor swiveling unit, offers multiple configuration options for increased flexibility to automate large and small volumes of small parts on the S11. Studer also offers a robotic automation system called the roboLoad. This external loading system for the S121, S131 and S141 includes a gripper, quick-change jaws and six trays for storing parts. For now, the roboLoad is best suited for unattended machining over extended breaks and night shifts, but the company expects to see more and more applications for robotic automation in grinding. All of these systems are designed to be set up quickly, without the need for programming.

The S100 is an entry-level grinding machine that’s designed to be flexible so that users are prepared to handle a range of workpieces. Users can choose from multiple spindle and wheelhead options. Photo Credit: Fritz Studer AG

The event also featured the new S100, which debuted at BI-MU 2022. It’s an entry-level machine that’s designed to be flexible so that users are prepared to handle a range of workpieces. The machine can be equipped with up to two internal grinding spindles, or one internal and one external spindle. It also has three wheelhead options: a fixed wheelhead, a manual with a 2.5-degree Hirth, or an automatic wheelhead with 1 degree Hirth. Additionally, users can choose to add automation with a loading interface and automatic sliding door.

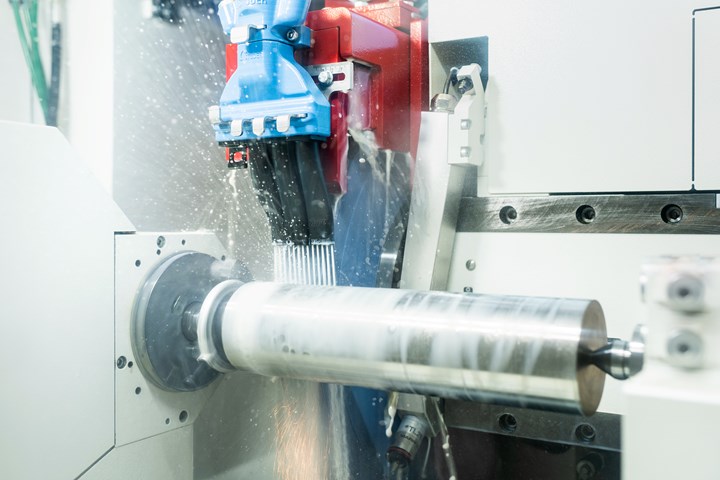

Studer’s SmartJet intelligent cooling system is said to reduce water consumption by as much as 40% and energy consumption as much as 50%. It includes a specially designed nozzle with channels that distribute coolant evenly, an optimized line system and pump, and sensor-supported intelligent control software. Photo Credit: Fritz Studer AG

Finally, 2022 brought concerns about an energy crisis in Europe, and concerns about sustainability remain for some companies. Studer’s SmartJet intelligent cooling system is designed to save energy and resources, reducing water consumption by up to 40% and energy consumption by up to 50%. It includes a specially designed nozzle with channels that distribute coolant evenly, an optimized line system and pump, and sensor-supported intelligent control software. Previously, when the machine was not in use, operators had to move nozzles away from the grinding wheel, because dripping coolant could cause the wheel to become unbalanced. But this also means that the operator had to move the nozzle back into place before starting the machine again, a time-consuming process that takes time and can lead to suboptimal nozzle position and/or unnecessarily high coolant consumption. Now, the machine can move the coolant nozzle away from the grinding wheel automatically, and move it back into position when needed. The software calculates the best exit speed for the volume flow based on the process taking place (roughing, fine grinding or finishing). The system delivers coolant precisely and repeatably, and it saves energy despite using high pressure and high exit speeds to deliver the coolant. All setup takes place on the machine control. SmartJet is standard on the S36, but will be added to the S31, S33, and S41 this year. It can also be retrofitted to other models.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

Machining 101: What is Grinding?

Grinding takes an abrasive — often attached to a wheel — and uses its many grains to cut a workpiece. Variations on this process are useful for a wide variety of applications.

Read MoreStuder Offers Entry-Level Grinding Machine

The S100 is suitable for grinding geometrically defined basic forms and contours for a wide range of parts, all of which can be generated with the machine’s interpolating axes.

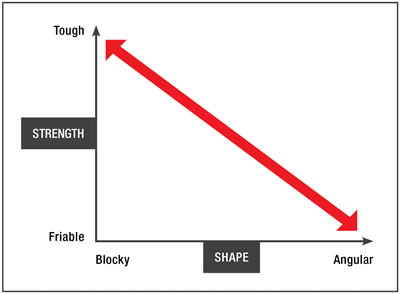

Read MoreChoosing Optimal Superabrasive Grains and Coatings

Superabrasive grain shape and coating composition play a large role in the suitability of grinding wheels for different applications.

Read More

.jpg;maxWidth=300;quality=90)