HEIDENHAIN CORPORATION

333 E State Parkway

Schaumburg, IL 60173 US

800-233-0388 | 847-490-1191

info@heidenhain.com

heidenhain.us

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

HEIDENHAIN CORPORATION Supplies the Following Products

- Calibration Equipment

- CNC Software, Stand-alone

- CNC Units

- Digital Readout (DRO) Units

- Digitizing/Scanning Systems

- Encoders/Resolvers

- Flatness Measuring Equipment

- Gages, Electronic/Digital

- Handwheels, Knobs, Cranks, etc.

- Interferometers

- Laser Measurement Systems

- Lifting & Positioning Equipment

- Linear Scales

- Machine Monitoring

- Non-Servo Electric Motors (Including Spindles, Drive Units & Power Feeds)

- Probes, Electromechanical

- Programmable Logic Controls (PLC)

- Retrofitting, Rebuilding, Remanufacturing Services

- Roundness Measuring Equipment

- Tool Condition Monitoring Systems

- Tool Presetters

- Tool Presetting Equipment

- Vision Systems

Trade Names Offered by HEIDENHAIN CORPORATION

- DIADUR

- Evaluation Software

- EnDat

- Specto

- Grid Plate

- Manual Plus M

- Double Ball Bar

- TNC

- Metro

- RSF

- Certo

- Acu-Rite

- LIDA

- Positip

- KGM

- EnDat 2.2

Editorial, News, and Products

-

IMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

-

Going Hands-On with Heidenhain and Acu-Rite Solutions

Heidenhain and Acu-Rite Solutions are offering several hands-on experiences at their booth this year, as well as internal components that reduce energy use.

-

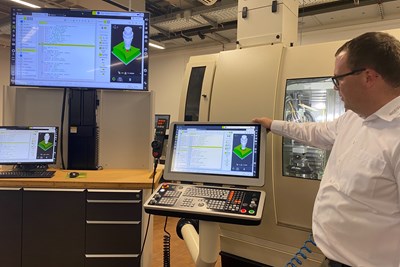

Heidenhain CNC Platform Provides Adaptable Interface

IMTS 2024: Heidenhain showcases the TNC7 CNC control platform, providing graphical instruction for the positioning of clamping devices and individual customization capabilities for users and machines.

-

Large-Format Machining Simplifies Tube Manufacturing

Downtime is the enemy of efficient manufacturing — a problem FIBA Technologies has addressed through purchasing a Soraluce FLP 14000.

-

Manufacturing Technology and Training in Europe

NTMA’s European Tech Tour exposed attendees to the latest technology and traditional training methods used by European manufacturers.

-

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

-

Acu-Rite Digital Readout App Enables Multitasking

The Heidenhain brand offers its droPWR with split-screen, enabling users to have more than one application displayed at a time.

-

Automation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

-

Flexxbotics Adds Compatibility for Hurco, Siemens, Heidenhain

FlexxCNC enables machine shops to integrate Universal Robot cobots onto any machine in its shop.

-

Heidenhain CNC Control Provides Customizable User Experience

Eastec 2023: The TNC7 provides virtual simulation of the machined part and work envelope.

-

Heidenhain Introduces User-friendly Turning Control

TurnPWR was developed for lathe machinists to support manual and automated operation.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Heidenhain Introduces In-Process Gage to Check Tools

The TD 110 tool breakage detector can determine whether a tool is broken off by more than 2 mm as it passes within a machine tool.

-

Putting Flexible Controls in Users’ Hands

At IMTS 2022, Heidenhain is launching programs that make getting its controls as simple as using them.

-

Haimer USA Models a Streamlined Toolroom

Haimer USA is celebrating its 20th anniversary with a live demonstration of its digital toolroom. Find out more past the aluminum panther.

-

Bluetooth-Enabled Digital Readout System

IMTS22: The interface of the droPWR system enables connection to multiple machine configurations in one tablet, including for milling, turning and grinding machines with up to six axes.

-

CNC Control Offers Greater Functionality

IMTS 2022: Heidenhain’s CNC control enables machine manufacturers to adapt the user interface to their machines for shopfloor-centered manufacturing.

-

AMO Speed Sensor Enhances Milling/Turning Machines

The WMK 3010S rotational speed sensor records spindle data, including rotational speed, operating time and temperature.

-

Heidenhain Launches New Machine Monitoring Platform

PlantMonitor enables companies to simultaneously monitor and analyze production data at multiple sites where at least one machine is equipped with a Heidenhain TNC control/StateMonitor software.

-

CAD/CAM Software Offers Enhanced Functionality

The latest enhancements are designed to give users increased convenience and faster programming tools for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

-

Heidenhain Touch Probe Offers High Speeds and 3D Accuracy

Heidenhain’s TS 760 touch probe offers 1 µm accuracy while keeping compatibility with the TS 740 and providing the same additional data as the TS 460.

-

Five-Axis and Clever Controls Support Medical Manufacturing

Kern’s Micro Vario and Heidenhain’s TNC 640 control give M5 the precision and accuracy it needs to successfully micromachine medical parts.

-

Heidenhain's Encoder Fine Tunes Robotic Movements

Heidenhain’s new encoder provides both reliable feedback to a robot’s motor and accurate position measurement to its controller to enable safe and accurate motion.

-

New Encoders From Heidenhain Implement Metrology Designs

Heidenhain’s new encoders allow machine manufacturers to obtain multiple measurements simultaneously and facilitate correcting deviations on the fly.

-

Heidenhain Offers Magnetic Ring Encoder

The ECM 2400 encoder from Heidenhain is an absolute modular magnetic angle encoder that is designed to resist contamination and offer functional safety.

-

Heidenhain's LIC 3100 Encoder Offers Simple Mounting

Heidenhain says its LIC 3100 absolute kit encoder enhances the efficiency of linear motors and offers forgiving mounting tolerances.

-

Renishaw's Free CARTO 4.2 Update Enhances XM-60

Renishaw’s CARTO 4.2 software suite provides new features for calibration equipment, notably extending the measurement range of the XM-60.

-

Heidenhain Upgrades ERA 4000 Series Encoders

Heidenhain’s ERA 4000 modular angle encoder has been upgraded for reliability, efficiency, and improved machine feedback.

-

Heidenhain StateMonitor 1.3.0 Improves CNC Connectivity

The Heidenhain StateMonitor 1.3.0 software upgrade simplifies data viewing and control process evaluation for CNC manufacturers remotely and in real time, and is compatible with both Heidenhain and non-Heidenhain controls.

-

Heidenhain Opens West Coast Headquarters

The new headquarters consolidates Heidenhain’s Fremont, California, technical support operation into the company’s expanded San Jose business center offices.

-

Large Equipment Offerings Buoyed by New CNC

To complement the strengths of many of its larger machine tools, Tarus has added a Heidenhain CNC to benefit those manufacturers seeking high-quality contour surface milling capabilities.

-

Acu-Rite's DRO300 Enables Control of Sinker EDMs

The Acu-Rite 300-series digital readout (DRO), available from Heidenhain, now enables users to control sinker EDM machines.

-

A Job Shop Approach to Automation

Through patient research and smart investing, this job shop has slowly grown its capabilities and is moving toward lights-out manufacturing for prototype work.

-

Heidenhain's TNC 640 Gen 3 CNC Expands Machining, Monitoring Capabilities

The Gen 3 version of Heidenhain’s TNC 640 machine control is designed for three- to five-axis milling, turning and grinding operations with up to 24 axes.

-

Acu-Rite Offers Software Upgrade for Digital Readouts

Heidenhain’s Acu-Rite brand offers a free software upgrade for its 100, 200 and 300 models of digital readouts (DROs).

-

CNC Machining and Motorsports

Have a look at some of the new manufacturing equipment spotted in “Machinery Row” at the recent Performance Racing Industry Show.

-

November 2019 Product Spotlight: 5-Axis Machining

This month’s Modern Equipment Review Spotlight focuses on five-axis machining technologies.

-

Product Spotlight: Measurement and Inspection

This month’s Modern Equipment Review Spotlight focuses on technologies for part measurement, tool setting and machine inspection.

-

Acu-Rite's DRO300 Can Now Control Sinker EDMs

Heidenhain’s Acu-Rite brand has introduced software for its 300-series digital readout (DRO) that now allows users to control a sinker EDM machine.

-

Heidenhain Opens New Regional Headquarters in Colorado

Whereas previously the Central U.S. sales region was managed by either the company’s Illinois or California headquarters, the new Colorado location will now handle this region as well as Mexico.

-

Heidenhain, Mastercam Introduce Five-Axis Postprocessor

In a collaborative aimed at enabling five-axis machining for those using Heidenhain TNC controls and Mastercam CAD/CAM software, the companies have introduced a new postprocessor.

-

Heidenhain's TNC-CNC Academy Offers Training for Users of All Levels

The company states that completing these classes will allow TNC users to improve efficiency and accuracy of the parts they machine.

-

Heidenhain’s Quadra-Chek 2000 Automates Inspection Routines

Heidenhain’s Quadra-Chek 2000 evaluation unit is designed for everyday measuring and metrology tasks in parts inspection applications.

-

Data-Driven Manufacturing Scales Down

An automatic gaging station demonstrates the potential of shopfloor connectivity at the level of the individual machine tool.

-

Acu-Rite Moves Production to Heidenhain's Chicago Headquarters

“The production of the Acu-Rite products is now going strong in Illinois. At the same time, we continue to invest in the Acu-Rite R&D department that remains in Jamestown, New York,” says John Parker, Heidenhain’s machine tool business development manager.

-

Vertical Knee Mill CNC Now Also Configurable for Bed Mills

Eastec 2019: At Heidenhain’s booth, the Acu-Rite Millpwr G2 control will be highlighted, marketed as an easy-to-operate CNC for vertical knee mills.

-

Touchscreen Digital Readout Provides Customizable Settings

Heidenhain’s ND 7013 digital readout (DRO) model replaces the ND 780 and offers an improved user interface and touchscreen, among other improvements.

-

Heidenhain Announces First North American Authorized Training Partner

Students and industry stakeholders can access and train on CNC systems and manufacturing equipment provided through Heidenhain’s first authorized training partner (ATP) in North America: the Advanced Manufacturing Center at the Community College of Denver.

-

Heidenhain Releases Online CNC Training Program

Heidenhain’s Heidenhain Interactive Training (HIT) 3.0 is said to provide advanced and apprentice-level CNC training and practice with Klartext programing and DIN/ISO programming within its three-axis machining learning packet.

-

Get Ready for Connected Machining by Preparing Your CNC Units for the Network

Priming and prepping your CNC machines to be connected to a network for monitoring is time well spent. The next step is choosing a machine-monitoring system that is the “right size” for your shop.

-

Lathe CNC Adds Features for Safety, Usability

Heidenhain has released upgrades to the CNC Pilot 640 lathe control.

-

Heidenhain Digitally Connects Machines from Many Builders

To showcase the new age of digital manufacturing, Heidenhain is using its control systems to connect equipment from many machine tool builders throughout McCormick Place to its booth in the Lakeside Center.

-

Heidenhain Appoints New CEO

Heidenhain recently appointed David Doyle as the company’s CEO following the retirement of current CEO Rick Korte in October 2018.

-

Various Motion Control Systems and Software On Display

IMTS 2018: Heidenhain offers motion control components and systems that can connect equipment from many machine tool builders.

-

Digital Readout Improves Readability, Eases Installation

Heidenhain’s ND 5023 digital readout (DRO) is designed for use with manually-operated machine tools.

-

DROs Offer Useful Software Features

Heidenhain’s Acu-Rite brand has released a line of three digital readouts (DROs) with software features and hardware for milling, turning, grinding and boring applications

-

Manufacturing News of Note: March 2018

IMTS 2018 opens registration, partnership enables remote access to CNCs, and other industry news.

-

Rotary Encoders Improve Robot Absolute Position Accuracy

Heidenhain introduces encoders designed specifically for the requirements of the robotics, medical and drive technology industries.

-

Heidenhain, Open Mind Partner to Connect CAM Simulator, CNCs

Open Mind’s Connected Machining module will enable networked Heidenhain TNC controls to be run from remote locations.

-

Monitoring System Connects Control with PCs, Mobile Devices

Heidenhain Corp.’s StateMonitor connects the company’s TNC controls with PC systems to enable users to view data and evaluate control processes remotely and in real-time.

-

Control Beyond CAM Unlocks Five-Axis Potential

Capabilities native to the CNC can facilitate levels of performance that would be impossible to achieve by relying solely on post processed part programs.

-

Gage Enables Accurate In-Process Measurement

The Heidenhain-Specto ST 3087 RC gage has a special housing for in-process measurements.

-

Understanding Direct-Drive Technology in Machine Tools

Today’s electric motors and electronic control systems offer important benefits.

-

Milling Machine’s CNC Leaves a Mark

When the prototyping process wasn't able to keep pace with creativity, installing a Heidenhain CNC on this manufacturer's Webb milling machine enabled faster machining, prototyping for this tattoo-machine developer.

-

Volumetric Compensation for Aerospace Applications

Präwest needed to improve machine tool accuracy. Etalon's LaseTracer-NC and KinematicsComp from Heidenhain enabled the shop to make dimensionally accurate workpieces without readjustments.

-

Rotary Encoders Couple Motor Feedback Systems to Torque Motors

Heidenhain supplements its line of inductive position encoders with the ECI 4000/EBI 4000 rotary encoder series.

-

Improving a Popular Mill-Turn Control

Gear hobbing capabilities, enhanced graphics and the ability to perform interpolation turning have been added to this well-known mill-turn control.

-

Control Capabilities Often Go Unused

The value of some control capabilities don’t become apparent until they are seen in use. Heidenhain supports its CNC users with a new Chicago-area training facility.

-

Know Your Control

A new training center will enable Heidenhain to support its CNC users by ensuring that they are aware of all that the control can do. The value of some control capabilities don’t become apparent until they are seen in use.

-

The CNC as Nerve Center

In the move to data-driven manufacturing, communication and data transfer have to be possible in all directions. The machine control is a sort of "hub" in the manufacturing environment.

-

What to Know about Torque Motors

Torque motors are commonly used in indexing tables on machine tools. This succinct article helps you evaluate this and other applications in which power transmission for rotation calls for the advantages of a torque motor.

-

Straight-Cut Control for Milling, Drilling, Boring

Heidenhain’s TNC 128 straight-cut CNC is designed for use with milling, drilling and boring machines.

-

Metrology Software Eases 2D, 3D Measuring

Heidenhain’s PC-based Quadra-Chek IK 5000 version 3.0.0 metrology software is designed to enable more convenient 2D and 3D measuring tasks.

-

Metrology DRO for Manual Measurement Systems

The ND 120 Quadra-Chek metrology digital readout (DRO) from Heidenhain is designed for manual measuring machines such as optical comparators and measuring microscopes.

-

CNC Mill Control Features Touch-Screen Interface

The Acu-Rite 3500i CNC control from Heidenhain features a touchscreen operator interface designed to optimize program navigation, editing, creation and verification.

-

A Model Machine for Titanium

Researchers develop a machine tool that controls vibration to mill titanium more productively. The machine relies on guideway systems delivering stiffness that is literally infinite.

-

Absolute Encoder for Electric Motors

Heidenhain says its ECI 119 absolute, inductive rotary encoder’s feature a low profile (19-mm height, 92-mm OD) and large through shaft (50, 38 or 30 mm) make it suited for electric motors in the electronics and packaging industries; general automation; robotics; plastic molding machines; and swivel and tilting axes.

-

Going To Great Lengths

Heidenhain LB 382C sealed linear scales enabled Ingersoll Machine Tools to meet the customer’s requirements for the largest five-axis gantry machine in North America.

-

Honing On A Horizontal Machining Center

A specially designed tooling package for honing operations, along with live, on-board gaging, allows critical honing operations to move to HMCs, thereby eliminating several separate steps on multiple dedicated machines.

-

Infrared Touch Probe For Mechanical Activation

The TS 642 touch probe from Heidenhain features mechanical probe activation and is compatible with both the company’s older controls and current third-party controls. This is especially useful for machines that are not set up to offer touch probes as standard options, the company says.

-

Absolute Linear Encoder

Incorporating absolute technology to a multi-substrate scale tape linear encoder design, Heidenhain introduces the LIC 4000. Besides its capability of absolute position measurement, this encoder is characterized by its high resolution of 1 nanometer and its serial EnDat 2.

-

Linear Scales Improve Lathe Accuracy

When Ford Automotive offered a contract to this Canadian automotive manufacturer for producing rear toe links, the company found its lathes simply weren’t capable of attaining the accuracy required to complete the job. In addition to enabling the company to win the contract, installing Heidenhain linear scales on the lathes reduced scrap rates and the need for frequent operator adjustments.

-

Accuracy Gain From Linear Encoders

If the position of a machine tool’s axis is measured using a rotary encoder, then potentially the ballscrew is being asked to perform two contradictory functions. The ballscrew both drives the axis into position and indicates that position—because the ballscrew lies in between the encoder and the moving element of the machine. Control technology supplier Heidenhain calls this “semiclosed-loop” operation.

-

Retrofits Invigorate Old Machine Tools

Retrofitting older machine tools with modern CNC, DRO and linear scales is often cheaper than buying new machines. According to two veteran retrofitters who have worked together for nearly 10 years, such retrofits can often bring outdated machines to like-new condition.

-

Flexible Grinder Streamlines Drive Shaft Production

When a bottleneck arose from an application involving multiple setups, this shop invested in a new grinding machine with a full B-axis. Since then, it has consolidated the troublesome operation from three machines to one.

-

Automotive Supplier Speeds Metal Removal With Boring Mill

In an industry where one in three shops has closed during the past 10 years, Fischer Tool and Die's business is thriving. According to the Temperance, Michigan shop, this is because its growth stems from die cast work for the automotive 'new domestics,' a term for transplants.

-

Retrofit Using Six-Axis DRO Offers Flexibility

Following a retrofit using this six-axis readout on a partial machine rebuild of a vertical milling/boring machine, this manufacturer is now benefiting from greater flexibility on existing machinery.

-

Interpolating Axes On Manual Machines

A DRO makes it possible to follow circular arcs on a manual machine.

-

Scales And DROs Customize Lathe To Keep Power Companies Running

When a multimillion-dollar turbine generator at a power plant needs to be repaired, time is of the essence. This company rehabilitates and rebuilds existing generators.

-

California Specialty Parts Machinist Has No Room For Error

Much of the current equipment at this plant is German and Swiss machinery, including two Deckel mills (FP4 and FP3), a Bridgeport mill and Schaublin (10-inch) and HES (20-inch) lathes, among other various saws. In order to keep the parts as accurate as possible, the controls and DROs that are used need to be accurate and reliable.

-

Quicker Tool Change For Mills

This article examines a retrofitted mechanical drawbar system with a preset die spring that enables an operator to manually do what a machining center does automatically--change tools quickly.

-

Interpolating Curves

The ability to import complex curves into CNCs promises to let shops finally get beyond old limitations imposed by contouring with linear interpolation. Faster and smoother cutting will be the result.