Heidenhain's Encoder Fine Tunes Robotic Movements

Heidenhain’s new encoder provides both reliable feedback to a robot’s motor and accurate position measurement to its controller to enable safe and accurate motion.

Share

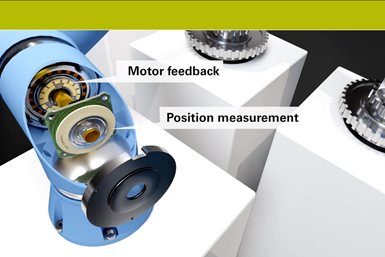

Heidenhain introduces the KCI 120 Dplus rotary encoder, which is designed to fulfill two needs via a single component in high accuracy robots. The encoder provides both reliable feedback to a robot’s motor and accurate position measurement to its controller to enable safe and accurate motion.

The KCI 120 Dplus encoder consists of one scanning head and two different types of rotor units that are connectable to a controller or drive via a single cable. Its small footprint (20 mm in height) and low weight makes it suitable for tight installation spaces for a variety of high-accuracy motion control applications.

The rigid design of the two-in-one encoder permits high vibration loads of up to 400 m/s² on the stator and 600 m/s² on the rotor. Due to its inductive scanning method, the KCI 120 Dplus rotary encoder is resistant to contamination and magnetic fields.

The KCI 120 Dplus encoder is available with functional safety capability and, with measures in the control, can achieve SIL 3 safety rating.

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

.jpg;maxWidth=300;quality=90)