Improving a Popular Mill-Turn Control

Gear hobbing capabilities, enhanced graphics and the ability to perform interpolation turning have been added to this well-known mill-turn control.

Share

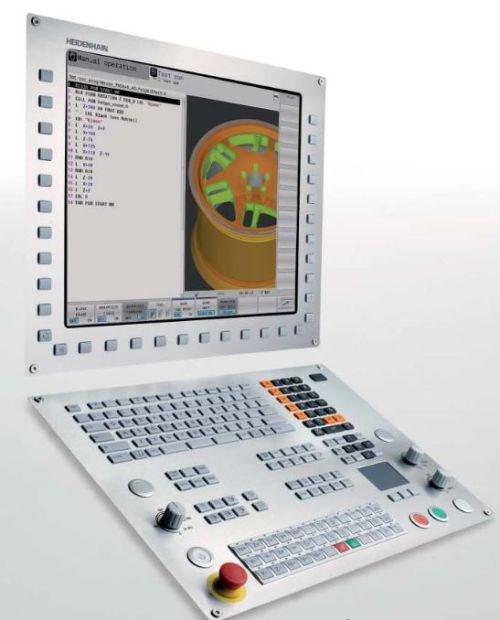

Heidenhain has added new cycles and features to its TNC 640 high performance mill-turn control such as enhanced graphics, interpolation turning and gear hobbing capabilities.

While making shop visits I’ve noticed that most programmers and operators tend to prefer a particular make of machine control over others. Devotees of the Heidenhain TNC 640 contouring control for mill-turn machines will be pleased to learn of new features now available on this unit, in particular one that allows for hobbing external cylindrical and helical gear teeth.

Known as Cycle 880, this machining process is performed through synchronization of the tool and lathe spindles. The cycle positions the rotary axis to the required tilting position and performs the infeed movements to the workpiece in the radial direction, and the milling movements in the axial direction.

The latest version of the TNC 640 also includes a new graphics package with a CAD viewer that opens any *.Step, *.Iges and/or *.Dxf file and allows an operator to evaluate the workpiece at the control. In addition, a new interpolation turning feature is available that is especially well suited for manufacturing large, rotationally-symmetric sealing surfaces, the company says, and for machining the housings of components of power plant technology in energy generation applications.

The TNC 640’s new graphics package includes a CAD viewer that opens any *.Step, *.Iges and *.Dxf file and allows an operator to evaluate the workpiece at the control.

Machine tool builders will appreciate the optional Dynamic Collision Monitoring (DCM), for which Heidenhain created a M3D converter. This is a PC tool with which CAD files of components in the machining envelope can be merged, edited and added to the collision monitoring program. Watch a video of the TNC 640 here. Also consider making an appointment to visit the company’s five-axis machining lab in Schaumburg, Illinois, which features a new machining center equipped with the TNC 640 control.

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.