Flexible Grinder Streamlines Drive Shaft Production

When a bottleneck arose from an application involving multiple setups, this shop invested in a new grinding machine with a full B-axis. Since then, it has consolidated the troublesome operation from three machines to one.

Share

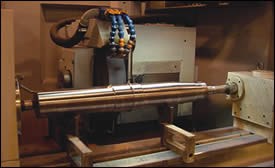

Twin Disc, a manufacturer of marine transmissions, grinds shafts of all lengths, weights, shapes and sizes. According to the company, the only thing all these shafts have in common is precision—very close tolerances and unforgiving surface finishes. Flawed shaft production can result in transmission failure. Thus, Twin Disc strives to use the best grinding technology available. So, when a bottleneck arose from a labor-intensive shaft-production process involving multiple setups, the company invested in a new grinder equipped with a full B axis. Since then, it has consolidated the troublesome operation from three machines to one.

Based in Racine, Wisconsin, Twin Disc has been in business for more than 75 years making more than 30 different marine transmissions for pleasure craft, military vessels, tugs, pushboats and more. In fact, Allied forces depended on the company’s transmissions to drive some 40,000 landing craft loaded with troops and supplies onto beaches during the Normandy invasion and throughout the South Pacific during World War II. In addition to marine vessels, the company makes transmissions for mining industry trucks and for various military vehicles, including the Bradley armored personnel carrier.

The two plants in Racine have a combined 551,271 square feet of manufacturing space and about 400 employees. The company uses a total of 21 cells, 14 of which are manufacturing cells for milling, turning, grinding, drilling, finishing and other such operations. The others are used for assembly, process completion and so forth. The company performs all operations except heat treating in-house.

The drive shafts are produced in 10 different diameters with various tapers. The shafts range from 8 to 48 inches long, with diameters ranging between 0.5 and 10 inches. The company holds tolerances between 0.0002 and 0.001 inch and surface finishes from 10 Ra to 40 Ra. Materials include 1144, C1144, 4145, 4140 and 8620 steel alloys as well as some stainless. Order quantities range from a single shaft to 500 pieces.

The company had been looking for a process change in the production of transmission shafts. Two grinders were used to grind the straight ODs, and a third was used for plunge grinding tapers. Terry Andersen, grinding team leader, programmer and machine operator, says this was a slow, operator-intensive process. Shafts had to be refixtured from the OD grinders to the plunge grinder. To improve productivity, the company wanted a grinder with a full B axis to combine the processes in a single machine.

When the company began searching for a flexible grinder to do shaft work in one shot, everyone was “a little leery,” Mr. Anderson says. There weren’t many manufacturers to choose from, and certain shaft dimensions eliminated some right away. At one point, the company actually acquired a grinder with a full B axis. However, the machine wouldn’t hold diameter size or taper tolerance and was not consistent, leading the company to continue with the old method.

“There was another company that was just coming out with a full B-axis machine, and they maintained they could accommodate our specs, tolerances, surface requirements and shaft dimensions, but we decided against it,” Mr. Anderson says. “This was going to be their first machine of this type, and frankly, no one wants to be anyone’s guinea pig—especially when you couple this with our previous experience.”

Eventually, the company settled on the Kellenberger Kel-Varia cylindrical grinding system with the Heidenhain GRINDplusIT control. A key factor in the company’s acquisition of the machine was its ability to hold tight tolerances while grinding tapers. On many shafts, the taper is nothing more than a press fit. Most of the tapers’ surface requirements are 40 Ra, but some have an angle of 30 to 1, which is less than a 1-degree taper.

“We had to have a machine that could handle that kind of range of demand,” Mr. Anderson says. “It had to be flexible, agile, rigid, and above all, repeatably consistent in holding very tight tolerances.”

The machine’s hydrostatic guideways are designed to provide accuracy and avoid friction and stick-slip movement. It features absolute measuring in the B axis, incremental, distance-coded scales in the X and Y axes and a high-resolution C axis. The grinder can also be equipped with a second B axis for more dimensional stability and profile accuracy.

The B axis permits automatic positioning of the wheelhead at any angle. For positioning accuracy, it includes a precision worm gear and distortion-free clamping. A Hirth coupling, which indexes at 2.5 degrees, also contributes to positioning accuracy. The Kel-Set automatic grinding wheel measurement system enables automatic movements to the measuring ball and to the grinding system, and it stores position information to the control system. When swiveling the wheelhead into any angle, the system automatically accounts for the positions of the wheel edges. In addition, the option of interpolating the X and C axes allows grinding of non-round shapes such as polygons, free contours and eccentric forms. For various types of grinding operations, the machine can use universal, diagonal and tandem-type wheelheads.

The grinder’s Heidenhain control features a Windows 2000 operating system, a graphics editor, expanded grinding cycles, intermediate dressing at the push of a button, comprehensive tool management, several reference points for each grinding wheel, remaining-travel display and more.

“The Kellenberger not only met all our requirements, but it was a proven machine, so we didn’t have to worry about working the bugs out of a new design,” Mr. Anderson says. “It’s been very reliable, and most important, it holds tolerances and surface finishes with remarkable repeatability.”

Because the company runs as many as 1,200 different shafts, change-over and setup are very common. However, according to Mr. Anderson, the new grinder makes this easy.

“Depending on what’s involved, we can changeover from shaft to shaft in about 10 minutes, especially if we’re not changing centers, and it’s strictly a matter of moving the tailstock and changing the driver,” Mr. Anderson says. “If you need to change centers and drivers, then you may be up and grinding in 20 minutes or less.”

About a year after purchasing the first Kellenberger, Twin Disc bought a second. With the exception of a hydraulic tailstock to handle even heavier shaft work, the second machine is identical to the first. The two machines reside in a single cell, and one operator runs both.

“We’re able to run twice as much product as before,” says Gary Pope, plant manager. “One operator does two shafts at once, and they come off finished. We run these machines 6 days a week, 24 hours a day, and we’ve already seen improvements in productivity. The accuracy and repeatability couldn’t be better.”

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)