CAD/CAM Software Offers Enhanced Functionality

The latest enhancements are designed to give users increased convenience and faster programming tools for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

Share

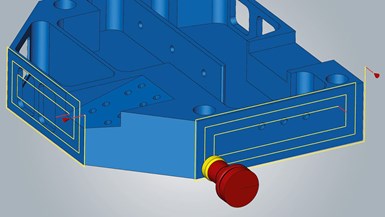

Fully automated hyperMill 3D plane machining searches for suitable, high-performance path layouts. Photo Credit: Open Mind Technologies

Open Mind Technologies’ hyperMill 2022.1 CAD/CAM software suite is said to offer enhanced features for more powerful NC programming in applications ranging from 2.5D to 5-axis. The software is designed to give users increased convenience and faster programming tools for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

Highlights in hyperMill 2022.1 include a break-edge function for contour milling, combined pocket milling together with a finish path enabling cutter compensation and increased efficiency for 3D plane machining. The automated 3D plane machining strategy is said to improve machining quality by searching for suitable path layouts according to parameters such as when adaptive pockets are present.

For improved tool data reliability and time savings, tool data (such as length, radius, corner radius, and tool number and name) can be transferred directly from hyperMill to a Heidenhain TNC640 control using the connected machining module. It is also possible to import calibrated tools from a tool management system into the software to create programs and then transfer the tool list or individual tool data to the machine.

New extensions to the hyperMill mill-turn capability include more streamlined programming and simulation processing and management for machines with main- and counter-spindle configurations.

[LB1]Our readers don’t do “blow molds” or the other processes I deleted below.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.