Data-Driven Manufacturing Scales Down

An automatic gaging station demonstrates the potential of shopfloor connectivity at the level of the individual machine tool.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Data-driven manufacturing does not have to be overwhelming or complex. Simple feedback loops from a measurement instrument to a CNC can provide a means for skills-strapped manufacturers to ensure quality parts with minimal involvement from shop personnel.

This was my thinking upon encountering an automatic gaging station that calculates and corrects turning insert wear offsets in real time. Available from Marshall Automation America Inc., the new U.S. arm of Indian machine tool builder Marshall Machines Ltd., SmartCorrect is designed to ensure defect-free, high-production turning in environments where skilled machine operators and inspectors are scarce. In a recent conversation, CTO Gaurav Sarup detailed how the system works.

Dedicated to specific parts and part families, each gaging station is configured with custom fixtures and digital measuring tools from companies like Heidenhain and Marposs. Various moving elements manipulate parts and probes alike to automate measurements that might otherwise be taken by hand. In addition to labor cost savings, both at the machine and potentially in downstream quality control, this physical automation eliminates the risk of mistakes like using the wrong measuring tool, using the right tool in the wrong way or using an uncalibrated tool.

From there, data-driven automation addresses two other common mistakes that lead to part defects. One is analysis of the inspection data. As inserts wear, measured features tend to trend larger, eventually reaching the limit of the specified tolerance. Generally, people track these measurements and periodically adjust tool-wear offsets to maintain specifications from part to part. Poorly calculated or poorly timed offset corrections can lead to scrapped parts, scrapped tools, or even a damaged machine, among other costs and delays.

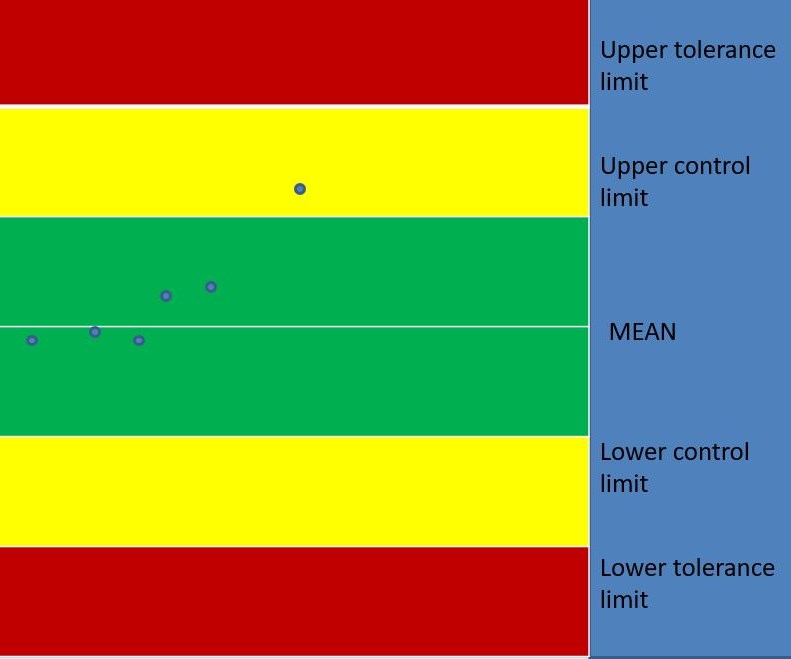

SmartCorrect automates offset calculation. However, this is possible only after a person does the work for 250 to 500 parts because the system must “learn” the extent of the variation within the process. Specifically, it must analyze enough data to calculate upper and lower control limits: thresholds that indicate when the measured part feature is trending too close to the upper or lower tolerance limit. The measurement that must cross the threshold to trigger an offset correction is the process mean: the average of the three most recent measurements. When this moving average strays into the zone between control limit and tolerance limit, the system calculates a new offset and sends it to the CNC for an automatic update. Subsequent parts stay in tolerance with no need for human input or even supervision.

The third error that causes part defects—entering the wrong data into the CNC—is nonexistent due to the gaging station’s direct connection with the lathe CNC (or two lathe CNCs, if the user desires). When purchased with Marshall’s own equipment, the gaging station is hardwired to the CNC. Offset update and calculation is performed by the company’s CLAP (Closed Loop Auto-Corrected Production) technology. For other lathes, the company generally recommends integrating Autocomp software from partner Caron Engineering. Connecting via Ethernet cable, this Windows-based system offers the same functionality as CLAP except calculation of the control limits, which must be entered manually.

All measurement and correction data is saved into a file for later analysis. Measurements can also feed into Marshall’s SmartInsert system, which derives the extent of insert wear to ensure it is changed only when its useful life is over. Autocomp provides similar tool life optimization for gaging stations connected to other builders’ equipment.

Available only on the company’s own machines is SmartChek, which provides health monitoring that is focused purely on the lathe’s spindle and two-axis assemblies. This system generates a daily digital health report to determine any deviations in terms of vibration, motor load or other parameters.

Overall, this automatic gaging station shows that data-driven manufacturing is possible without extra work, information overload or extensive and expensive storage and analysis capacity. Opportunities can also be found at the level of the individual machine tool.

Related Content

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreEasy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)