W Industries is a company that thinks big—big machines, big parts, and big growth. The last of these—big growth—is getting attention because the company is located in Detroit, Michigan, a location most people associate with contraction in the automotive industry and the decline of manufacturing.

W Industries, however, has been adding new equipment and more employees, despite the depressed economy. One of the new machines, called the Cybermill, is especially noteworthy. It is said to be the largest five-axis gantry machine in North America. Built by Ingersoll Machine Tools (Rockford, Illinois) the machine is roughly 28 feet wide and 240 feet long (with 10 feet under its gantry). It was installed in the spring of 2009.

“With this large mill as part of our mix, we are growing at a rate that no one really anticipated,” explains Jason Sobiek, director of aerospace manufacturing at W Industries. To support this kind of growth, the company expects to add 100 employees a year. Currently, the company has three Michigan locations and houses 24 mills. The workforce stands at around 400.

“With this Cybermill, we are now working on a program for the Airbus A350 airplane for Spirit,” Mr. Sobiek reports. This project consists of two long tools for the fuselage, both 16 by 70 feet. Together, the parts use only about a third of the machine’s table. To put the mill’s size into perspective, staff at W Industries estimate that its table could accommodate 78 Hummer H2 sport utility vehicles (without tires) stacked two-high and three-wide. With that amount of space, Mr. Sobiek says, many kinds of large structures can be machined, including large molds, jigs, fixtures and composite tooling, in addition to exceptionally long aerospace parts. The machine is “on duty” three shifts a day, seven days a week.

To be an effective asset, a machine of this size has to meet many requirements. Two of the most important are accuracy and efficiency. For the machine builder, meeting this challenge was partly dependent on providing accurate, reliable feedback to the control system. Holding tight tolerances was the primary objective, but a feedback system that streamlined startup and initial referencing procedures was also a priority. Ingersoll engineers certainly recognized that for a customer like W Industries, the earning potential of this machine is substantial, so every minute counts.

When developing plans for a machine of this size, designers were concerned that linear scales of the length required might not be available. “We approached Heidenhain Corp., one of our long-time partners, with this exceptionally long linear scale challenge,” says Martin Honer, a controls project engineer at Ingersoll. Heidenhain’s answer was the LB 382C sealed linear scale for the machine’s X, Y and Z axes. Because these scales could be delivered in 72-meter lengths (which the company says are the longest available in the world), they could cover the full length of the X axis. That’s an X axis that is three quarters the length of a football field. According to Mr. Honer, the positional accuracy on these scales is ±5 microns. Moreover, the LB scales from Heidenhain carry distance-coded reference marks, a feature that speeds and simplifies finding a home position. The larger and longer the machine, the more valuable this streamlining feature is to the end user.

Reference Marks

The distance-coded reference marks (semi-absolute) on the LB scales are extremely important on large machines because they allow them to “home” or ascertain their positions at startup very quickly. At every startup, subsequent electronic routines find the absolute reference (“home” position) after traversing a very small distance. Conventional machine referencing involves physically jogging the machine axes to a fixed home position that might be many meters away. Distance-coded reference marks speed and simplify such reference runs.

On W Industries’ Cybermill, for example, using distance-coded reference marks for the X-axis homing cycle is a great advantage because they can save more than three minutes over a typical system (with a home limit switch at one end of the table if the gantry is at the other end of the table), Mr. Honer explains. “In general, this system also saves machine wear and tear, and is more convenient for the operator, particularly if large workpieces are involved and axes may have to be moved in order to avoid collisions,” he says.

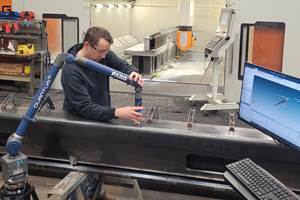

Because a total of more than 450 feet (150 meters) of the LB distance-coded linear scales had to be installed at W Industries, technicians from Heidenhain offered to assist in their installation. Staff at W Industries mounted the housings, but each of the 72-meter scale tapes, the bearing surfaces and the protective sealing lips were installed by Heidenhain over a five-day period. “Everything, including the intermediate gaskets and scanning units, had to be just right. The housings are dial-indicated and needed to be flat and parallel within 4 thousandths (0.004 inch). Then the scanning head and bracket had to be mounted correctly to provide a 60-thousandths (0.060-inch) air gap over the entire 72 meters,” says Paul Hood, a Heidenhain service technician.

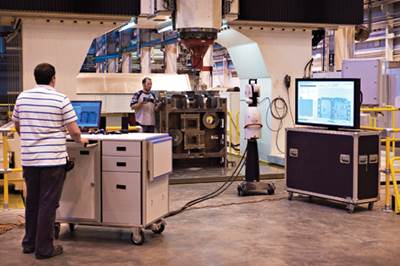

After the installation was completed, W Industries contracted with an independent machine calibration service to check the machine with laser trackers. The results verified that the machine’s accuracy met or exceeded specifications.

Spindle Accuracy Counts, Too

Spindle accuracy was also a priority for the machine tool builder, notes Mr. Honer. “Overall, accuracy and repeatability are critical on a machine of this size. It is important to note that the tools on the spindle of the gantry are moving on some pretty big arcs, and they need to be very accurate.”

The Cybermill’s spindle head operates at 16,000 rpm with 50 kW of power. “This amounts to cutting very accurately at approximately 1,000 ipm,” explains David Hislop, an NC programming specialist at W Industries. To handle the measurement of the angles within the spindle, the machine uses two RCN angle encoders, also from Heidenhain. One is on the C axis (the joint between the ram and the red spindle head) and the other is on the B axis (the joint that allows the tool to angle). The B axis must move ±100 degrees. “The angular positional accuracy on the spindle head is 20 arcseconds with repeatability of 10 arcseconds,” Mr. Honer says.

The evolution of this giant machine began in 2006 at Ingersoll’s facilities in Rockford, where it served as a shorter prototype. There it was tested and used successfully to machine the Invar tooling for the Boeing 787 wing skins. At that point, two gantries were installed on a single X-axis bed. This configuration made the machine more productive and flexible, while at the same time enabling it to accommodate very long parts.

As part of its diversification plans, W Industries ordered this machine in 2008 as a single-gantry machine with a much longer X axis. The addition of more gantries is always an option because the extremely long length makes it a much sought-after piece of manufacturing equipment. For example, the alternative energy sector is growing. “We can now machine any part of a windmill,” Mr. Hislop says, “from a blade, hub assembly, nose cone and so on. We believe we are unique in this ability because a turbine blade can be 100 feet long and a mold can be 200 feet long. We believe this is one of the only pieces of equipment in the world that can build these single pieces. We are quoting many windmill parts jobs right now.”

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)