Honing is a particularly critical operation for Quincy Compressor in Quincy, Illinois. That’s because the quality of a compressor’s cylinder bores greatly affects its efficiency, and honing is the final and most critical step in the process of bringing cylinder bores to specification. A high-quality bore finish ensures that the motion of the piston and the cylinder bore creates maximum air compression with minimum carryover. Carryover (sometimes called "blow-by") refers to the minute quantity of oil particles that pass by the rings on the piston when a compressor is running. So honing has received a lot of attention at Quincy Compressor, ever since the company began producing compressors for commercial applications more than 85 years ago.

Lately, however, the company has been very attentive to the efficiency of its manufacturing operations. In the last several years, the company has been streamlining its operations and implementing the principles of lean manufacturing. One goal has been to reduce setup time so that smaller batches of parts can be produced effectively. Achieving continuous flow in part production by combining operations on one machine has also been a key objective.

Thus, it’s not surprising that Quincy Compressor looked closely at the possibility of combining honing operations with other machining steps on CNC machining centers. By working closely with a cooperative machine tool builder, an innovative honing technology developer along with their integrated electronics gaging supplier, Quincy Compressor has been able to successfully run honing operations on two HMCs installed early this year. The key enabler in this project is a method of simultaneous honing of the cylinder bore and real-time air gaging of the bore size in the automatic mode.

According to Chuck Fisher, manager of operations support and facilities at Quincy Compressor, the success of this project was particularly gratifying because "everything came together and worked the way we had hoped and expected them to." The company is now able to finish-machine 15 different compressor bodies involving 11 different cylinder bore sizes, all of which required a honed finish. Cylinder bore quality has also improved substantially. Carryover has been reduced to extremely low levels compared to bores finished on the old dedicated honing machines. Moreover, the process has opened the door to new product designs, which were previously constrained by the inflexibility of the old machining line.

Deep Roots

Quincy Compressor established its foundation in the compressed air industry in 1920 with a reputation for engineered solutions, starting out in the vacuum pump business by offering farmers efficient cow-milking machines. Design engineers George Wall, John Kathe and George Gille joined several investors to create Wall Pump and Compressor Company, later renamed Quincy Compressor. In 1937, the company introduced the Quincy QR-25, a symbol of the company’s quality over the past 72 years. According to the company, these same durable characteristics are present in all of Quincy’s line of reciprocating compressors, which is manufactured in the Quincy plant. In 2005, the company became part of EnPro Industries, a family of specially engineered product manufacturers. Quincy continues to specialize in compressors for industrial applications in a wide range of markets, serving companies such as Harley-Davidson, Sara Lee, GE and NASA.

Until honing could be moved to CNC machining centers, compressor bodies were completed in four separate operations for facing, milling, drilling and honing. The machining line consisted of multiple machines, including several dedicated honing machines in the traditional vertical style. In 2007, Mr. Fisher and several manufacturing engineers attended an educational seminar on honing where they heard a technical presentation by Darrell Day, president of Bates Technologies (Fishers, Indiana), a company specializing in honing technology. Gathered around a tabletop exhibit, engineers from both companies began discussing the possibility of doing honing operations on a machining center.

It was clear that tackling this challenge would require a strong partnership that combines the expertise of all parties involved, and not just those of Bates Technologies and Quincy Compressor. Following Bates’ lead, the machine tool builder and the electronic gaging supplier would also have to contribute.

The Right Partners

Bates Technologies is one of the leading developers of specialized honing technologies for use on both dedicated honing machines and on many machining centers and flexible workstations. The company also designs honing tools, air gaging systems and honing consumables, such as abrasive honing stones and brushes. On Quincy Compressor’s behalf, the company approached several machine tool builders about the possibility of developing a honing system for automatic operation on a machining center. The honing tools would be stored in the machine’s tool changer and loaded in the spindle automatically. The machine would have to interface with the hone tooling package and the air gaging system.

The machine tool builder that Bates considered the most receptive to the proposed project was Mazak Corp. (Florence, Kentucky). This builder turned out to be the ideal partner. One reason is that Mazak is a strong proponent of multitasking machine tools. Successfully integrating a honing operation in this application would be a natural extension of the company’s emphasis on "done-in-one" capability. Also, the company’s technical center at its U.S. headquarters is set up to facilitate projects with technology partners.

Alan Huber, Mazak’s national applications manager, headed the builder’s team working on the project. He says the project involved some essential modifications to a standard HMC. In this case, the team determined that a pair of Nexus 6800 II HMCs would be the best choice for Quincy’s needs. These 50-taper machines are equipped with 80-tool magazines and a two-station pallet changer.

Modifications for honing included an additional compressed air line for the air gage on board the honing tool, a coolant inducer to deliver high pressure coolant to the body of the honing tool for activating the honing stones and a 10-micron coolant filter. Also, the machines’ controllers were modified so that a programmable logic controller (PLC) would respond to signals from the air gage. Mr. Huber explains that these modifications did not add significantly to the cost of the machines, but they did need to be installed while the machine was being built.

Honing Tools Honed For Automation

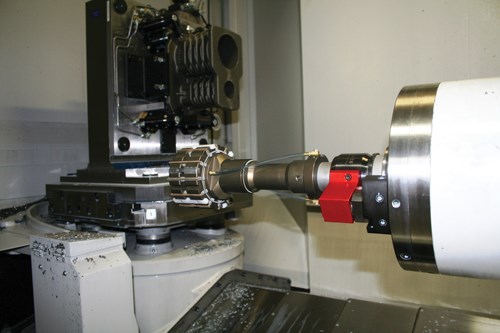

For its part, Bates Technologies had similar re-engineering tasks. David Chobany, vice president of Bates Technologies, explains that his company modified its honing tools to use lightweight aircraft aluminum for the tool shaft and hone head. This reduced the mass of the tool so that it could be safely handled by the tool changer without excessive wear on the spindle. Bates Technologies also had to design interfaces on the honing tool and the spindle face so that the coolant and air lines could be engaged automatically when the tool is loaded into the spindle. Although the company has considerable experience with gaging systems for automatic honing on dedicated honing machines, this was the first time it had addressed the needs for the automation of honing multiple parts with different bore diameters on CNC machining centers. For Quincy Compressor’s application, it developed 11 honing tool sizes ranging from 2.5 to 6.0 inches in diameter.

To develop the automatic electronic gaging system for this project, Bates Technologies worked closely with its partner, Metronics Inc. (Bedford, New Hampshire), a division of Heidenhain Corporation. The honing developer’s experience in air gaging along with Metronics’ advanced electronic equipment led to a customized gaging system referred to as the Bates Precision Air Gage System (PAGS).

Within this system, air pressure flowing through orifices on the body of the honing tool changes as the bore size increases. These changes are registered and reproduced in an electronic form through a proprietary air-to-electronic converter box mounted in the machine. This information is then passed through the Bates Gage Chek unit, which electronically provides the machine tool PLC with live information relative to actual bore diameter as the part is being honed. Once the part reaches final size, the machine ends its cycle for this bore. The Gage Chek unit also acts as a digital readout of the bore size (within microns) as it grows larger with each stroke of the honing tool.

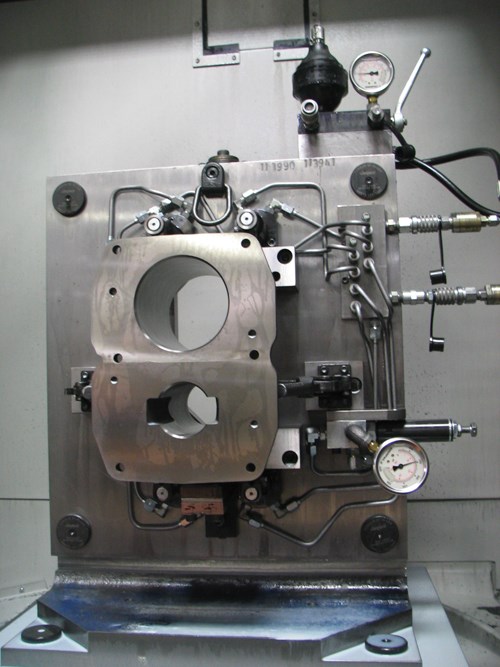

Quincy Compressor took delivery of the two HMCs in January 2009. By March, the QT10 line of compressor bodies had been approved for honing operations on the new machines. However, considerable effort preceded this approval. The company worked with H & B Quality Tooling, a local tooling and fixturing company, to design and build fixtures for mounting the cylinder blocks on the pallet changers of the machining centers. These fixtures feature interchangeable mounting plates that can be taken on or off for the different part numbers processed on the HMCs. The pallets are loaded and unloaded manually.

Kerry Davis, another VP at Bates Technologies, worked with Quincy manufacturing engineer Jeremy Shade and process improvement technician Chris Mitts to optimize the grade of abrasive stone for each bore size and tweak the corresponding feed, speed and stroke rates. This team also trained the machine operators.

(Almost) Like Any Other Tool In The Magazine

In operation, the typical honing process on the HMCs works like this: After face milling, drilling, tapping and chamfering of the compressor housing is completed, the bore is finished with a single-point tool, and then checked with a touch-trigger probe. If the bore size is within tolerances, the appropriate honing tool is retrieved from the ATC and inserted into the spindle, interfacing with the coolant inducer, along with the rotary union and spindle-face stop block that allows compressed air to flow to the gage. Because the part remains clamped throughout these steps, the centerline of the honing tool matches that of the boring bar, thus maintaining bore straightness and roundness.

When the coolant flow is turned on and reaches the prescribed pressure level, the honing stones expand outward against the walls of the cylinder as the tool rotates and feeds in and out of the bore. As material is removed with each stroke of the honing tool, the air gage measures and displays the changing size on the DRO unit. When final size is reached, the gage unit signals the CNC to shut off coolant flow to retract the honing stones and begin the procedure for withdrawing the tool from the bore.

By precisely controlling RPM and the feed rate, a crosshatch pattern at the pre-determined angle can be imparted on the wall of the bore. (This crosshatch is the signature feature of a honed cylinder bore—it allows the oil to be retained for a perfect seal between the cylinder and the rings on the piston.) After completing this stroke, the honing tool returns to the tool magazine.

"Any Model, Any Day"

The successful integration of honing on the HMCs enables the company to adjust part production rapidly to more nearly match the part mix needed by incoming orders and forecasted model runs. The goal, according to Mr. Fisher, is to support the assembly of "any model, any day." He reports that the new HMCs, and other process improvements, have brought the shop floor very close to this goal.

Although Quincy Compressor may not be the first manufacturer to benefit from honing on a machining center, it certainly won’t be the last. Moreover, this test of the live, on-board gaging that enabled this successful application has implications yet to be explored. For example, some of the largest boring tool manufacturers have been in discussions with Bates to determine how they may utilize the electronic gaging feedback from the honing operation to monitor the boring operation that precedes it. By tracking the initial bore size reading transmitted by the hone’s air gage, wear on the boring bar’s insert edges can be adjusted to control size. This may also allow timelier tool changes. The savings on an automotive engine block line from implementing this concept could substantial.

.jpg;maxWidth=970;quality=90)