Share

The pace of technology change in manufacturing over the past four years increased in ways that were difficult to comprehend in real time. These years were marked by uncertainty amid a global pandemic and the cancelation of IMTS, the International Manufacturing Technology Show in 2020.

IMTS 2022, therefore, offered a unique perspective on how shop floor technologies have evolved over the last four years. But the biggest takeaways from this year’s show were not necessarily the new technologies on display (which were plentiful), but the ways in which metalworking OEMs are integrating existing technologies for increased automation.

Modern Machine Shop’s editorial team fanned out and hit all four halls of McCormick Place to learn more. What follows is a curated, photographic look back at what our editors experienced at this year’s show.

Automation Aplenty

Automation pushed into new territories this year, including automated in-process part inspection, automated data solutions for quality control, and fully integrated and automated production environments.

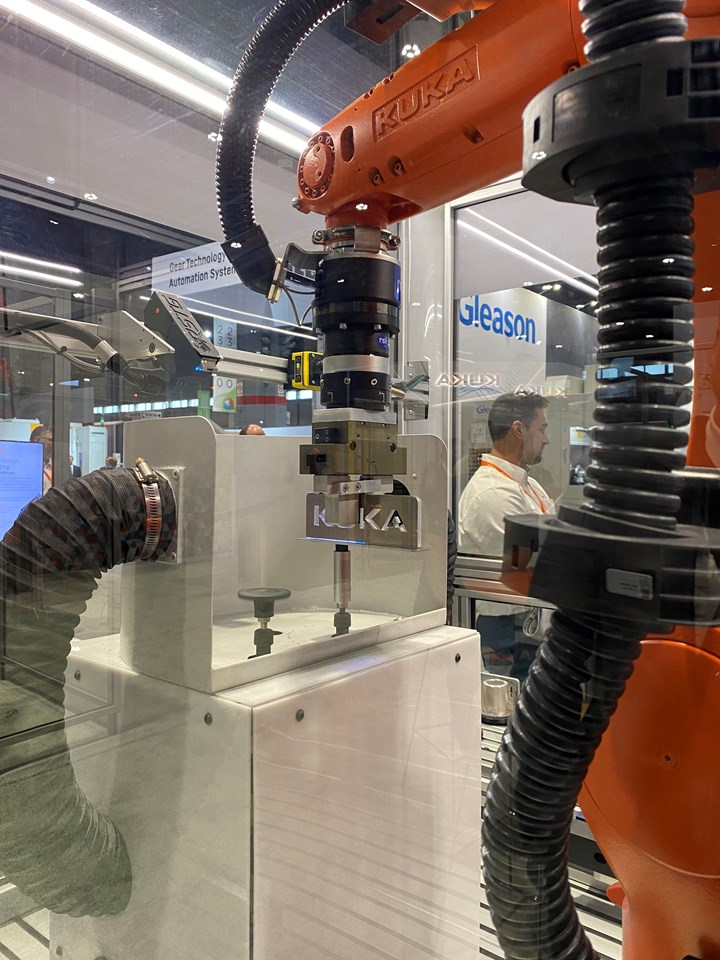

Kuka featured demonstrations from some of its partners in its booth, including this surface finishing cell from Reliabotics. The cell includes automated deburring and CO2 cleaning.

The Haubex vise changing system from Lang uses a machine’s toolchanger to automate part loading and unloading. A workholding hood, covering a Makro-Grip five-axis vise and workpiece blank, attaches to a toolholder in the tool magazine. The vise and blank are loaded into the work zone via a zero-point clamping system. When machining is complete, the hood returns to the workzone, removes the finished part and its vise, and brings them back into the tool magazine.

This automation cell from ANCA makes it possible for a cutting tool manufacturer to oversee between one and 10 grinding machines without the need for a caged-off area. Each grinding machine is equipped with a robotic loader in a compact cell, with an independent robot traveling between the cells and a tool-measuring machine.

The Zoller Robobox system can assemble shrink-fit tooling automatically. With a single attendant, the Robobox can assemble, measure and label dozens of tools, and offers lights-out capabilities.

Integrated Software Shows Its Potential

Several software providers promoted integrated software environments combining features from multiple programs. Marposs’ Maindo software, for example, collects information from machine monitoring and inspection systems, organizing the data on a unified dashboard. Users can take advantage of predictive capabilities to avoid crashes and can cross-correlate measurements and variables such as diameter and temperature to track the causes behind non-conformance.

Siemens’ integrated software portfolio takes a different approach, incorporating CAD/CAM, simulation, inspection and more within a single, cohesive environment — no file conversions necessary.

At IMTS, Siemens showed off a part for an electric car designed within its digital ecosystem. Taking the original part (right) as a base, the company designed an additively manufactured version, then developed finishing tool paths. The resulting part (left) weighed 45% less.

EVs and Sustainability Drive Innovation

Environmental and sustainability issues can be politically fraught topics in the U.S. Which is why is was fascinating to learn that, for many of the OEMs at IMTS, sustainability is not seen as a political issue at all, but instead is viewed as a movement that is driving advances in precision machining and energy efficiency.

For example, Mitsui Seiki was showcasing its new PJ 812, a three-axis CNC vertical jig mill designed for high-precision contour machining and boring applications. How does this relate to sustainability? Consider plastic bottle manufacturers. Mold-and-die shops serving this industry must accomodate customers demanding thinner and thinner bottles to save on material costs. Meeting this demand requires extremely tight tolerances for the molds, which, in turn, requires high-precision boring machines.

A mold on display at Mitsui Seiki’s booth, showcasing the ultra-precise boring capabilities of its new PJ 812 three-axis CNC vertical jig mill.

Sustainability issues were directly at the heart of Heidenhain’s LC xx6 series of linear encoders. This new encoder model reads through dust and water, eliminating the need for continuous cleaning via air hoses. Removing air hoses makes operation far less expensive, while also using 99% less CO2.

The Heidenhain LC 116 and LC 416 encoders resist contamination, thereby eliminating the necessity of air purging in many instances. This saves on operating costs, and lowers machine downtime. Image courtesy of Heidenhain.

Electric vehicle production has also required redesigned equipment across many stages of manufacturing, from machining to inspection. That isn’t to say that this equipment will not prove useful for other tight-tolerance industries, however. For example, Marposs introduced its OptoCloud laser-triangulation point cloud system for inspecting EV engine stators, but noted that the no-contact approach is also useful for aerospace and medical applications.

Marposs’ laser-triangulation point-cloud OptoCloud EDU system is faster than a traditional CMM, with company spokespeople saying it can validate a motor stator’s 240 electrical contacts in 30 seconds. Image courtesy of Marposs Corp.

Evergreen Classics Retain their Place

In addition to advanced technologies, many classics still attracted attention.

Spindle speeders have been around for years, but the prospect of making high-speed machining more attainable makes them consistently popular for companies like Platinum Tooling.

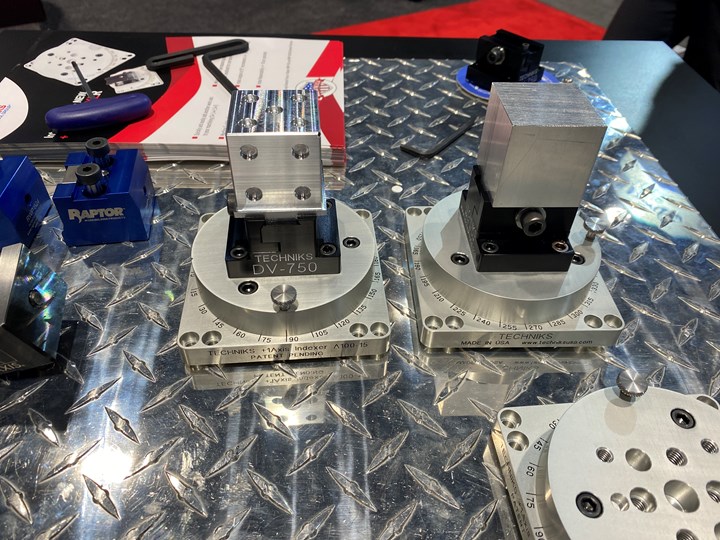

Techniks’ +1 Axis Indexer adds an extra axis of rotation to small parts, enabling users to fixture multiple individual parts on a machine table.

A Great Start for the Next Generation

The next generation of manufacturers is key to the continued success of the industry. At the Smartforce Student Summit, high school and college students engaged with cutting-edge manufacturing technologies such as additive manufacturing, automation, digital twins and virtual reality. Students in robotics clubs from schools across the country demonstrated their own creations, giving visitors an idea of the upcoming generation’s capabilities.

Cardinal Manufacturing, a student-run job shop in Wisconsin, was at IMTS to learn and network. At the show, Cardinal was sharing its newest resource: a self-published book detailing what the shop has learned over the years and offering tips for running a successful student-led business.

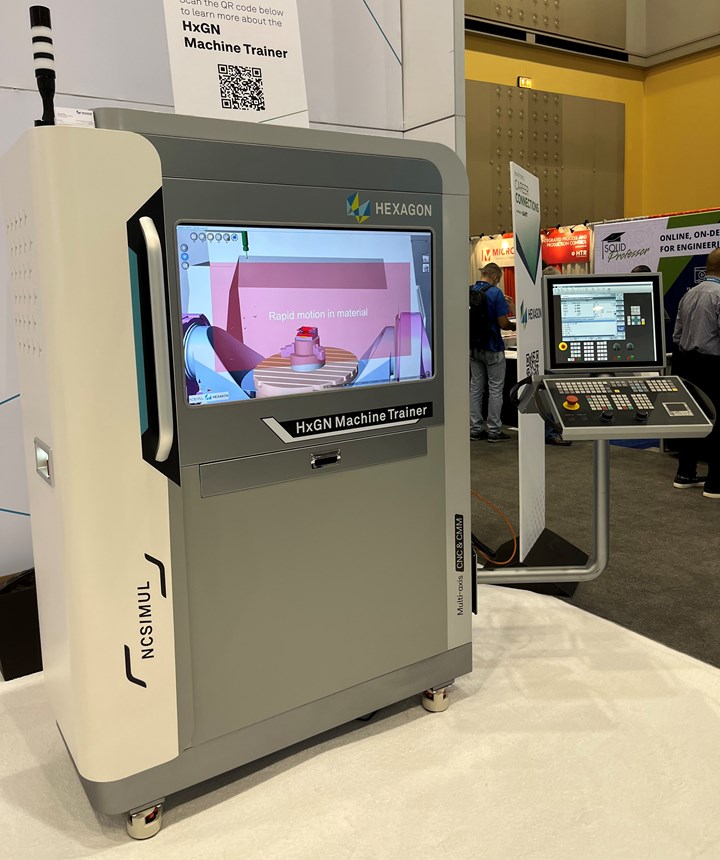

Even beyond the Student Summit, many companies offered machines and connectivity devices designed to train new and inexperienced workers. These devices include the Hexagon Machine Trainer, which uses the same interface as a CMM or five-axis machine to provide students and new hires with the chance to practice programming these machines. Heidenhain is also positioning its Bluetooth-powered DROpwr as a tool for wirelessly connecting multiple devices to an encoder interface box.

The ability to define machine kinematics within the Hexagon Machine Trainer’s onboard NCSIMUL software means that users can verify their programs with the Machine Trainer as they would run on the shop floor before making a test cut. Programming for five-axis can take place in a Heidenhain, Siemens or FANUC control interface as needed. Image courtesy of Hexagon’s Manufacturing Intelligence division.

Heidenhain’s DROpwr iOS app enables manufacturers to replace individual, physical DRO systems with Bluetooth-enabled encoder interface boxes. The app can then display information from multiple encoder interface boxes at once or operate in split-screen functionality to maintain visibility on another document (such as a part drawing).

A Final Takeaway

Like at every IMTS, companies working in aerospace, automotive, medical and more found an overwhelming array of technologies, top-tier guidance and business opportunities. From students seeing their first machine tool spindle to experienced shop owners looking for opportunities to increase automation, the show had something to offer for everyone. But after a four-year absence amid challenging times, IMTS 2022 was, more than anything, a needed reminder that manufacturing touches every aspect of our lives.

Related Content

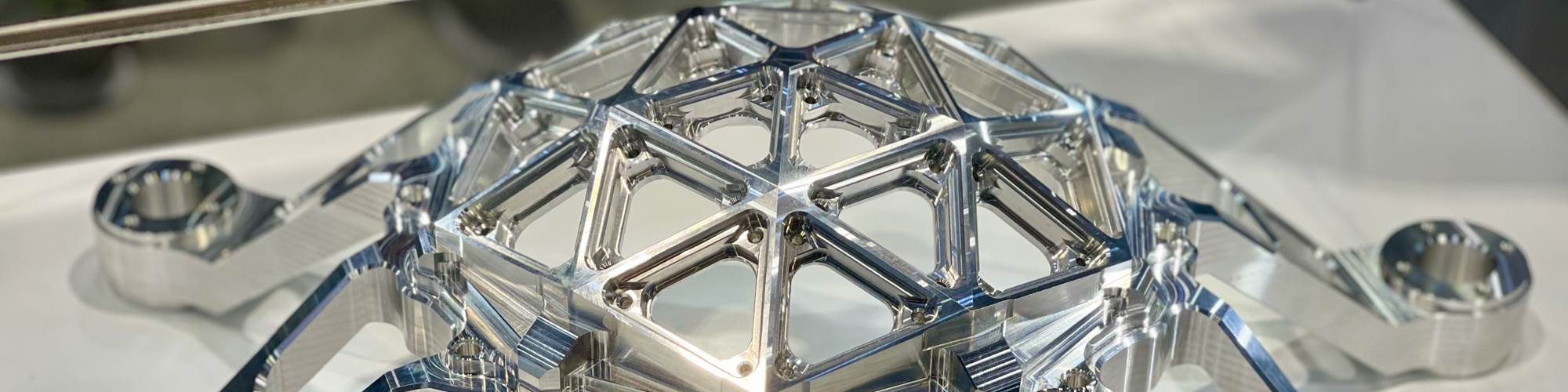

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More