Get Ready for Connected Machining by Preparing Your CNC Units for the Network

Priming and prepping your CNC machines to be connected to a network for monitoring is time well spent. The next step is choosing a machine-monitoring system that is the “right size” for your shop.

Share

Buzzwords like the Industrial Internet of Things (IIoT), Industry 4.0 and Big Data are floating around the industry, and some of that buzz is probably very useful for the right application and for large production companies. But is this really what a job shop needs? Do shops want to stream all their shop data to the cloud right now, or is it more important to connect their existing equipment to monitor individual machine tools’ uptime and optimize workflow first? To address this situation, let’s break it down in some small pieces that shop owners should consider before they jump into the pool with the “data sharks” who offer sophisticated systems that are seemingly designed to analyze an entire company’s global production with countless bar graphs and pie charts that only a data scientist will understand.

To begin, our first recommendation is to start on the shop floor because that is where the data should be collected and analyzed first. This is the place where the shop makes parts. It’s where the machine operators are working, programming and running the machine tools. It’s where shop personnel see firsthand if they are making good parts and why the machines are running or not.

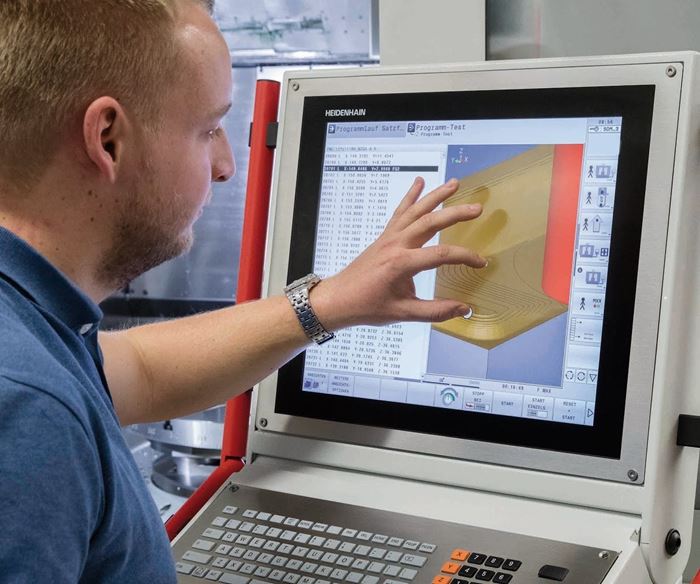

In this environment, the machine tool’s computer numerical control unit (or simply the “CNC”) plays a pivotal role, as it is the main interface with the operator and the main source of data about machine performance. The CNC is located at a central position within the process chain where it crosses the shop floor. In a very real sense, the CNC is naturally positioned to be the nerve center for data-driven manufacturing. That is why Heidenhain, for example, has prepared its TNC family of machine controls to serve as a data hub in the emerging digital-manufacturing environment.

Keeping in mind that vital production data comes from the shop floor and that much of this data comes from and goes to the CNC, a shop should consider the following questions before making a decision about connecting machines to a network for process monitoring.

What Is the End Goal?

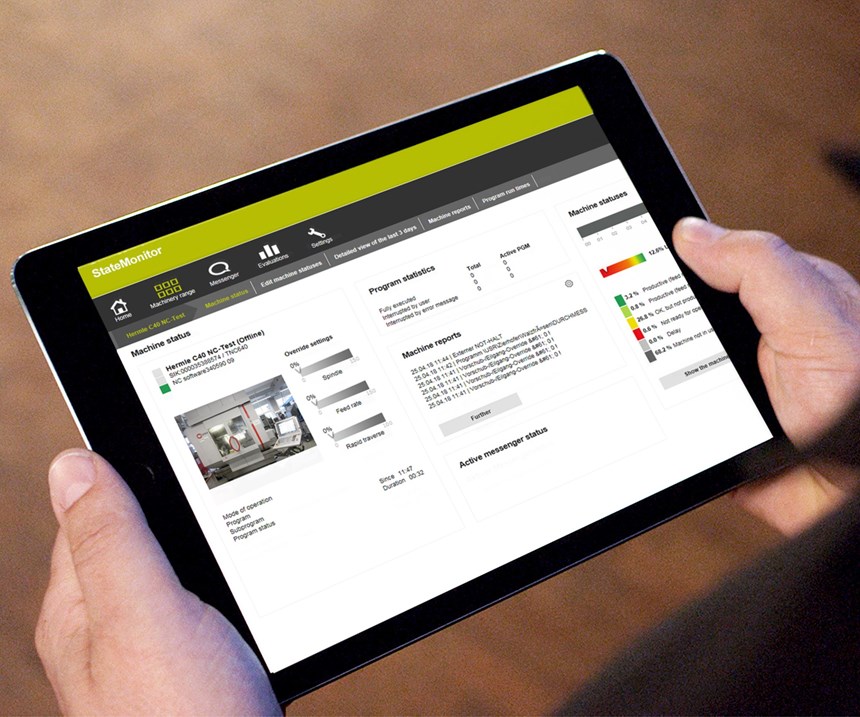

Determine first what performance indicators you would like to measure and consequently what are you going to do with the data. Many shops look at overall equipment effectiveness (OEE) but some shops may find it more useful to look primarily at one component of the OEE formula. Focusing on availability (machine uptime) may lead to the greatest initial gains. Be sure that top-level management concurs with this goal and is committed to supporting improvements based on data, not their gut feeling. Be sure your data includes the data generated by the machine along with direct operator input, such as reasons for downtime. Heidenhain’s StateMonitor, a machine-monitoring application for machines with a CNC, is designed to combine all machine data and operator input into an understandable, actionable format.

What Shop Equipment Can be Networked?

Most shops have many different types of machine tools. That also means different types of CNCs and often different generations of the same CNC brand. What each CNC is able to output about machine performance can be vastly different in kind, quality and quantity. The MTConnect protocol, a set of royalty-free interoperability standards for shopfloor equipment, can be helpful to connect different types of machines if older machines can use an adapter for converting data into this format. Remember, MTConnect and other data-exchange protocols do not make up for data that a machine and its control are not designed to provide. Legacy machines with simple PLC-based control systems may need add-on sensors so even basic data can be acquired. Another hurdle may be that even some recent machine tools will not provide all the data necessary to analyze the process well enough, making it difficult to calculate accurate spindle loads and relate them to speed and feed records. Typically, native machine data from a control such as the TNC will be the most comprehensive and complete, enabling StateMonitor to yield the most accurate and detailed analyses.

Do You Preset Tools or Use Part Probing?

If you want maximum run time on your machine, a preset station for tools and maybe even for parts is essential. However, if you rely on the operator to enter the presetter data manually, you will expose your automated process to additional risk of using wrong tooling data in your machining program. The ability to load the data from your tool preset station directly into the control’s tool table avoids this danger. To facilitate this data exchange, Heidenhain offers a software utility called Software Development Kit (SDK) that enables original equipment manufacturers of peripheral devices such as a tool presetter to create their own interfaces to transfer data into the TNC or read data out of the TNC via the DNC protocol interface. CAM software providers can also use the SDK for sharing data.

Do You Have Proven Postprocessors for Each Machine Control?

When was the last time you reviewed the postprocessors in your CAM library? Postprocessors are critical components of your production flow, so checking to see that all postprocessors reflect the latest release of your CAM software as well as the latest updates to your CNC systems is recommended. Some controls (the Heidenhain TNC is one example) are backward compatible, meaning a post developed 10 years ago for an iTNC 530 will still work for a machine with a new TNC 640 mill-turn control. Of course, CNC suppliers develop many new features and functions all the time, so check with your CAM provider to ensure that the latest postprocessor version takes advantage of the newest control cycles and features.

Do You Use Verification Software or Machine Simulation?

Program verification is critical if you machine parts on five sides in one setup or use full five-axis simultaneous machining. You want to make sure the tool path and rapid moves do not cause collisions that could destroy your part, or worse, your spindle and machine. Here are some recommended choices: Acquire one of the simulation software utilities like Camplete or Vericut to verify your programs with the actual tool path and actual machine kinematics. A cost-effective option for shops using the TNC 640 is to download the virtual control software from the Heidenhain website onto a PC and run the NC program on the simulator to check the collision-monitoring function before sending it to the machine.

Now get going. Priming and prepping your CNC machines to be connected to a network for monitoring is time well spent. The next recommendation for implementing a machine-monitoring system is to find one that is the “right size” for your shop. With Heidenhain’s StateMonitor, for example, a shop can connect as many as 30 machines. This system is a plug-and-play solution for shops with TNC controls that are 10 years old or less. The system works also with the Acu-Rite Millpwr G2 for knee mills. With the MTConnect protocol, most types of milling or turning machines can be connected easily, along with electrical discharge machines or laser machines.

StateMonitor is installed on a server in the company network as a machine data acquisition/machine-monitoring application. It captures many important data ranging from the current machine status to machine reports and override settings, all the way to usage history and errors or service notifications, which can be sent to mobile devices. Data can be exported to spreadsheets for further evaluation and archiving. The system also enables the operator at the CNC to provide information about program availability, missing tools, causes of downtime and more.

So, go head and start your journey into the world of connected machining and digital manufacturing, but take it one step at the time.

Related Content

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreFour Questions (& Answers) About Data-Driven Process Improvement at CNC Job Shops

How can shops can make informed decisions using data-driven feedback to improve shopfloor efficiency and profitability? And how will these technologies differ between high- and low-volume production?

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)