Siemens Industry Inc.

Motion Control — Machine Tools

390 Kent Avenue

Elk Grove Village, IL 60007 US

800-879-8079 | 847-640-1595

cnc.us@siemens.com

usa.siemens.com/cnc

IS THIS YOUR COMPANY?

Video Gallery

THE 2024 CHRISTMAS EVENT. Let's machine a snowman!

The holidays are upon us and there's no better way to welcome them than with our annual Mr. CNC Christmas event. Each year I ...

Sinumerik One – Discover its Cutting-Edge Features!

We are thrilled to invite you to an exclusive webinar showcasing our latest breakthrough in CNC technology – the Sinumerik One.

It is October already

As Seen On Modern Machine Shop

Siemens Industry Inc. Supplies the Following Products

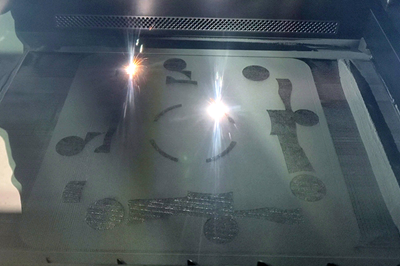

- CAD/CAM for Additive Manufacturing

- CAD/CAM Software

- CNC Software, Stand-alone

- CNC Units

- Communications Networks & Data Transmission Equipment

- Encoders/Resolvers

- Job & File Management Software

- Leasing & Financing

- Machine Monitoring

- Maintenance & Repair

- NC Program Optimization

- NC Verification

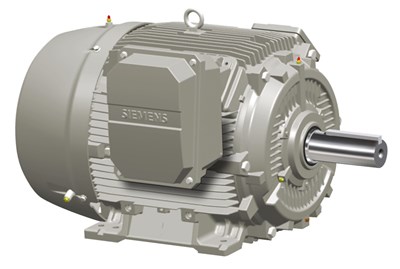

- Non-Servo Electric Motors (Including Spindles, Drive Units & Power Feeds)

- Part Design Software

- Programmable Logic Controls (PLC)

- Replacement & Repair Parts

- Retrofitting, Rebuilding, Remanufacturing Services

- Robot Controllers

- Servo Motors, Linear

- Servo Motors, Rotary

- Spindles

- Tool Condition Monitoring Systems

- Tool Design

- Training

- Training & Consultancy for Additive Manufacturing

Trade Names Offered by Siemens Industry Inc.

- solution line

- SITRAIN

- ACRAMATIC

- SINUTRAIN

- SIMODRIVE

- SIMATIC

- ShopMill

- Motion Control Information System

- ShopTurn

- ManualTurn

- SINAMICS

- MCIS

- power line

- SINUMERIK

- powerline

- SINUMERIK Edge

- Mcenter

- Analyze MyWorkpiece

- Analyze MyPerformance

- Manage MyMachines

- MACHINUM

- Run MyVirtual Machine

- Create MyVirtual Machine

- SIMOTICS

Editorial, News, and Products

-

Digital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

-

Siemens Partners With Desktop Metal to Scale AM

The collaboration will integrate Siemens technology in Desktop Metal’s AM 2.0 systems, including operational technology, information technology and automation.

-

Siemens Focuses on the Future of Industrialized AM

Siemens partnered with Roboze, Xerox Elem leading up to launch of its Charlotte Advanced Technology Collaboration Hub (CATCH) facility focused on advancing additive manufacturing technology.

-

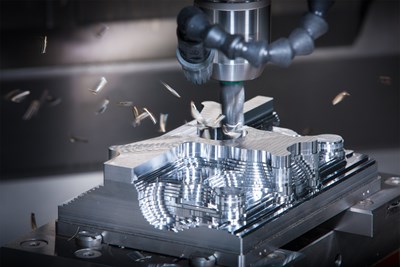

Do Modern CNCs Call for a New Programming Paradigm?

Complex workpieces such as AM parts present demanding toolpath challenges. But meeting the challenges reveals how much precision we’ve had all along — we just need the measurements and methods to use it.

-

Siemens Launches New Enclosed Drive System

Siemens says the Sinamics G120XE is ideal for industries such as oil and gas, petrochemical, wastewater, power plants, industrial climate control and refrigeration.

-

SolidCAM Expands Machining Software to Siemens NX

SolidCAM iMachining software is said to achieve short cycle times – regardless of industry, material or machine – with its patented “morphing spirals,” intelligent island separation and moating.

-

Nagel Introduces Flexible Bearing Race Superfinisher

The patent pending part drive system can reportedly handle a range of part diameters without any changeover. The new system includes several industry features to make the machine more flexible and productive.

-

Siemens to Showcase Sinumerik One at Two Upcoming Events

With the new Sinumerik One, Siemens is launching an intuitive machine operation that it believes offers CNC users more efficiency and flexibility.

-

Siemens Announces Simotics SD200 as Low-Voltage Offering

Providing high productivity and energy-efficient operation in all torque ranges, these new cast-iron motors are built to power pumps, fans, compressors, hoists, winders and similar equipment in harsh environments.

-

BASF and Siemens Energy Partner to Lower CO2 Emissions

BASF and Siemens Energy have partnered to accelerate implementation of emission-lowering energy and chemical production technologies.

-

New Grinding Machine Utilizes Unique Kinematics

A novel grinding machine uses three rotary tables stacked off-center to provide full control over the grinding wheel’s X and Z axis, as well as its angular position, creating an unusual solution to grinding.

-

Siemens and Ingersoll Expand Digital Enterprise Partnership

Siemens and Ingersoll are expanding their digital partnership to enable create digital twins of Ingersoll’s tools and further advance robotics and CNC.

-

Siemens Offers Free AM Network Services to Doctors and Hospitals

Doctors, hospitals and organizations in need of medical devices as well as designers and service providers with medically certified printing capacities can now register for free access to the Siemens AM Network.

-

September 2019 Product Spotlight: EMO Hannover

Catch a preview of some of the metalworking technologies to be on display at EMO Hannover next week in this special product spotlight.

-

August 2019 Product Spotlight: Robots & Automation

This month’s Modern Equipment Review Spotlight focuses on robotic arm and related technologies.

-

Siemens' AnalyzeMyWorkpiece /Monitor Enables Process-Parallel Quality Control

EMO 2019: Siemens expands its software portfolio for machine tools with AnalyzeMyWorkpiece /Monitor, which enables continuous monitoring of workpiece production in machine tools.

-

Siemens and Comau Collaborate to Offer Sinumerik CNC Incorporating Robot Control

Through a cooperative agreement, Siemens and Comau now offer a jointly engineered Sinumerik Run MyRobot DirectControl product.

-

Siemens, Identify3D Partner on Monitoring Platform

Controlled through the CNC on the machine tool, the combined service is expected to represent a significant element in IP protection.

-

Milling Postprocessor Supports Sinumerik 808D Control

CNC Software, producer of Mastercam CAD/CAM software, has released a postprocessor for three-axis and four-axis milling machines designed with help from Siemens CNC engineers, that provides support for Siemens’ Sinumerik 808D CNCs.

-

Italian Machining Technology at BI-MU 2018

The 2018 edition of the Italian machine tool trade show emphasized start-ups, additive manufacturing and the automotive industry.

-

Siemens Embraces Digitalization at IMTS

Siemens Industry is showcasing its commitment to the world of digitalized manufacturing at its booth this year.

-

Variety of Industry-of-Things Software, Hardware

IMTS 2018: Siemens Industry Inc. offers a range of products, including the Sinumerik CNC hardware and software solution, basic milling and turning applications, multi-axis machining centers and automated work cells

-

Digitalization as the New Critical Success Factor

Digitalization gives manufacturers the capability to increase productivity across their entire value chain, with integrated feedback throughout.

-

Siemens Hosts 2018 SCADA/IPS Days

The company’s management, sales and support teams as well as solution partners and end user companies gathered for product presentations, technology discussions and a market trend outlook.

-

Now Is the Time to Digitally Connect Your Factory

People and processes will interact more effectively when digitalization makes it easy to share data on an internet-enabled network.

-

Manufacturing News of Note: March 2018

IMTS 2018 opens registration, partnership enables remote access to CNCs, and other industry news.

-

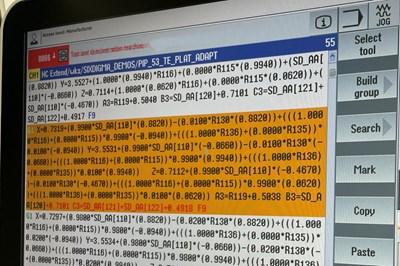

CNC Interface Facilitates Manufacture of Complex Workpieces

Siemens Industry’s Sinumerik Operate integrates HMI-Advanced, ShopMill and ShopTurn into a single machine tool user interface.

-

How Part Data Control Will Expand and Simplify the Supply Chain

Digital rights management for manufactured part files will enable OEMs to enforce manufacturing requirements at a distance, as an alternative to in-person certification of suppliers.

-

Siemens Partners with Identify3D for Manufacturing IP Theft Protection

ID3D has integrated its security and traceability technology into the Sinumerik CNC and Siemens PLM portfolio for data encryption and decryption.

-

CNC Software Compensates for Axis Nodding

Siemens is releasing new functions with its Sinumerik 4.8 CNC software, designed to significantly improve the speed, precision and safety of machine tools.

-

What Is an IIoT Platform?

The foundation of data-driven manufacturing is an IIoT platform: the hardware and software package that connects devices and equipment and enables management of data flows and applications.

-

CNC Directly Incorporates Robot Controls

As a result of a cooperative agreement with Comau, Siemens offers the jointly-engineered Sinumerik Run MyRobot DirectControl enabling the integration of robot kinematics into a CNC system.

-

The DMDII Is a Showcase for Digital Manufacturing

A tour of Siemens’ Digital Manufacturing and Design Innovation Institute in Chicago revealed the potential scope of the “digital enterprise” concept.

-

Siemens, FFG Partner to Consolidate Machine Tool Digitalization Efforts

The effort joins Siemens’ Digital Enterprise Suite and MindSphere operating system with the Taiwanese manufacturer’s machine tool technology.

-

CNC Software Is the Sensor

Recent developments in CNC technology enable the use of add-on software for monitoring cutting conditions in the machine tool.

-

Control Technology Provider Demonstrates How CNC Advances Factory Digitalization

How users and builders of machine tools can benefit from factory digitalization and integration is the main theme of the Siemens booth at EMO 2017. Highlights include enhancements to the company’s Sinumerik CNC software as well as the introduction of MindSphere, a cloud-based platform for hosting applications that enable manufacturing companies to more fully digitalize their operations.

-

CNC Enables Simultaneous Machining with Two Tools

Siemens has expanded the scope of its Sinumerik 828D CNC family with software version 4.7 and the PPU 2xx.3.

-

Siemens Outlines Five Stages of Digitalization in EMO 2017 Preview

Siemens presented five stages of digitalization with end-to-end solutions from its integrated portfolio at a preview of its 2017 EMO exhibit.

-

Siemens Expands Its Technical Application Center

The facility’s machine lab now has three milling machines, a turning center, a robotics center and an NX-CAM training station.

-

ModuleWorks, Siemens Partnership Adds Collision Avoidance to CNCs

The latter’s Sinumerik 840D sl controller can now be equipped with the former’s real-time crash-detection and collision avoidance software.

-

CNC Panels Promote Clear, Efficient Operation

Eastec 2017: Siemens will present its Sinumerik 15" and 19" blackline panels for its Sinumerik 840D sl control system.

-

Siemens Launches Workforce Development Program

The program revolves around Sinutrain, a PC-based CNC simulation system that enables instruction in CNC programming for milling and turning.

-

CNC Operator Panels Reduce Chance of Incorrect Entries

Siemens Industry’s Sinumerik Blackline OP 015 Black and OP 019 Black operator panels are designed for the Sinumerik 840D sl CNC system and offer new options for machine operation.

-

Additive + Subtractive Won’t Need Further CNC Advances

Today’s control technology is ready for these machines, and for more challenging integrations than this.

-

CNC Enables Four-Axis Turning without CAD/CAM System

The expanded contour machining cycle for Siemens’s Sinumerik controls now facilitates four-axis turning on lathes, enabling two turning tools, opposite one another, to machine a workpiece simultaneously for reduced machining time.

-

Integrating Robot Programming into the CNC: One Example

This combination of robotics, CNC, workholding and machine tool technologies resulted in a streamlined way to integrate and program an automated machine-tending process.

-

Sophisticated Software for Solid Gear Design

Whether your computer platform is standalone or part of a suite, desktop or on the cloud, there’s a gear design package developed specifically to meet your needs.

-

Operator Interface Equipped with Functions for CNC Turning, Milling

Siemens has added three new functions to its Sinumerik Operate graphical user interface for turning and milling machines.

-

Video: C-Axis Interpolation for Turning on a Machining Center

Controlling spindle revolution in time with the helical feed enables a single-point tool to “turn” the bore of this part.

-

The Foundry's Way Forward

An established supplier of short-run castings just opened and staffed a new, fully equipped, in-house CNC machine shop. Taking ownership of machining will improve the company’s range of services to customers as well as its quality control.

-

Standardized CNC Improves Production of Power-Generation Equipment

Voith Hydro standardized the majority of its machines with a CNC platform from Siemens Industry Inc. to help machine a variety of large, complex parts.

-

CNCs Enable Small- and Large-Scale Production

The Sinumerik 828D family of CNCs from Siemens includes the 828D Basic T and 828D Basic M controllers.

-

CNC Improves Accuracy of Milling, Turning Machines

Siemens’ Sinumerik 808D Advanced CNC offers a range of design features said to improve the accuracy, surface finish, safety and communication of the control for basic milling and turning machines.

-

Video: Machine Shop of the Future

Siemens produced this attractive video to illustrate what it sees as a likely representation of the machining facility of the future.

-

CNC Operator Panel for Advanced Machine Tool Applications

Siemens’ OP 019 CNC operator panel enables design integration into the Sinumerik Operate graphical user interface and Sinumerik840D sl CNC for use on milling, turning, grinding, laser-cutting and other machine tools.

-

Control Package Helps Speed Production

After cutting precision parts in one third of the original time, Task Force Tips was able to justify its initial investment in an Index automatic production lathe fitted with a Siemens control package.

-

Operator System Enables Direct Connection

Siemens’ Sinumerik OP 019 operating panel can directly connect to the Sinumerik 840D sl CNC control for milling, turning and laser machining with the TCU 30.2 thin client unit, an operator system for CNC applications.

-

“CNC Retrofit” Often Means More

This video testimonial provides an inside look at the myriad benefits Major Tool & Machine has realized from a new CNC platform—but like other, similar projects, implementing that platform required a complete motion system overhaul.

-

Retrofits Done Right

Manufacturers considering anything less than a total motion system upgrade could be selling themselves short.

-

Robotics Integration for Workpiece Handling

mxAutomation for Sinumerik CNC is a joint development between Kuka and Siemens for operating both a machine tool and robot from a single control panel.

-

Lean from the Beginning

How would you design a new plant if you could begin today? Rolls-Royce Crosspointe is a major manufacturing site that was planned from the outset with the expectation that continuous improvement would always be part of its culture.

-

Entry-Level CNC for Lathes, Milling Machines

Siemens Drive Technologies Division’s Sinumerik 808D is an entry-level CNC for standard lathes and milling machines.

-

Basic CNCs Aimed at Job Shop Users

The Siemens Sinumerik 828D Basic T for turning and Basic M for milling are designed to enhance these machining operations in job shops.

-

Basic CNCs Are Aimed at Job Shop Users

The Sinumerik 828D Basic T for turning and Basic M for milling are designed to enhance these machining operations in job shops.

-

Machine-Control Combo Ensures Speed, Precision

Five-axis HMCs from Grob with Sinumerik 840D sl CNCs from Siemens facilitate cost-effective production of cylinder heads at BMW’s motorcycle manufacturing plant in Berlin.

-

Siemens Drive System Enhanced With Industrial Ethernet Connectivity

Siemens’ Sinamics S120 drive system features Profinet, Ethernet TCP/IP and EtherNet/IP connectivity to maximize flexibility for industrial Ethernet communication.

-

Motion Controllers Enhance Productivity

Simotion D445-2 and D455-2 DP/PN motion controllers from Siemens Industry are suited for a variety of production uses.

-

A Model Machine for Titanium

Researchers develop a machine tool that controls vibration to mill titanium more productively. The machine relies on guideway systems delivering stiffness that is literally infinite.

-

CNC Controls Manage Energy Consumption

Sinumerik Ctrl-Energy is designed to provide energy-efficient operation of machine tools, encompassing Sinamics drive systems and motors, CNC and drive functions, PC software solutions and services.

-

CNC System Boosts Productivity for Aerospace Machining

Siemens' Sinumerik 840D is a CNC system designed to increase performance and productivity on the manufacturing floor, particularly in high speed and five-axis aerospace machining, the company says.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Faster Production of Inside Threads

Modern tools, control and software create a range of options for producing inside threads efficiently.

-

From Image to Implant

Demo shows custom implant made on commodity-level machine.

-

Economical CNC Retrofit Package

Siemens Industry offers a CNC retrofit package that is said to economically improve productivity and efficiency.

-

CNC Retrofit Package

Siemens offers a CNC machine tool retrofit package based upon its Sinumerik 802D sl system platform.

-

5 Axis Volumetric Error Compensation for Large Machine Tools

System simultaneously corrects tool position in multiple axes to tighten machining accuracies on large machines that cut complex shapes.

-

Machine Control Aimed At Job Shops And Beyond

The Sinumerik 828D control is said to bring to the "job shop machine tool" a range of features and functionality typically reserved for high-end machine tools.

-

CNC Training Software Available On CD ROM

Siemens Energy & Automation offers its SinuTrain solution, a package of CNC training software on CD-ROM that runs with Windows XP. To further speed the program-generation protocol, NC programs can be developed and simulated using a direct connection to the company’s CAD systems. In this way, mill and lathe operators not only learn the control language commands, but also visualize part programs on PC screens that are identical to actual machine screens.

-

CNC Maximizes Machining Efficiency

Siemens' Sinumerik 840D control allows this shop to run its machines virtually glitch-free.

-

Seeing More For CNC Multi-Spindles

Motor technology, machine design and software possibilities all improve the economies of these sophisticated high-volume machines.

-

CNCs Accomodate Various Automation Setups

As one Barrington, New Hampshire shop recently discovered, machining diesel engine turbocharger impellers from Type 2618 aluminum requires multiple passes to machine the blades.

-

CNC Analysis Aids Machine Design

This company designs, engineers and builds machines in conjunction with its sister company in a 200,000-square-foot facility with approximately 200 employees. When it set out to build a five-axis, high speed machining center for use in the production of critical components, it faced numerous challenges.

-

“Too Hard” Is Just Right

A user of ultrasonic machining looks for parts that are too hard to cut on other machine tools.

-

CNC Retrofit Improves Accuracy And Productivity For Aerospace Components

By using the Sinumerik 840D, the results include reduced setup time, improved surface finish, reduced secondary finishing operations and significant improvements in overall productivity.

-

Bridging The Gap Between CAD And CNC

The postprocessor is the last software link between an ideal CAD model and a "real" machined part. To what degree the postprocessor can take advantage of a CNC's capabilities, and vice versa, determines the number of available programming options and degree of programming difficulty. CNC/postprocessor rapport is particularly important for high speed machining (HSM).

-

CNC Features Important For Lathes Used On Oil Valves

The company says it likes the CNC program test feature because each tool has its own geometry page and up to four offsets, making things less complicated.

-

Multi-Axis Control Helps Supplier Stay Out In Front In Ported Cylinder Heads

This company was founded in 1997 and currently operates full CAD/CAM programming, CNC machining, bench/dyno testing for cylinder head and engine performance, and in-house welding and finishing departments. It uses a variety of multi-axis machining centers that have rotary tables for five-axis part articulation.

-

Stringer Solution

To reduce cost while improving quality and reproducibility, Airbus UK decided to implement a fully automated process able to machine a stringer complete. The existing production facility was stripped to its steel framework and adapted for the new process.

-

Control Keeps Press Manufacturer Competitive

The Web Press Division of KBA North America Inc. (York, Pennsylvania), a builder of high speed presses for newspaper printing, recently investigated its need for improved control in the production of parts used in its equipment construction.

-

Curve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

-

Controller Helps Meet Demand For Foreign Oil

The cutting of thousands of slots in extensive lengths of pipe requires large-scale machining, and the demand for such pipe is steadily increasing as Middle East oil sources become less dependable. Controls on these machines are crucial.

-

Toward A Truly Open Manufacturing Environment

Modular systemization is revolutionizing machine tool control. CNCs are only the beginning.

-

Five-Axis Machining For The Masses

Control technology continues to make five-axis machining easier to use. Many special considerations - particularly qualified tools for pivoting-spindle machines - are no longer essential to the process.

-

Interpolating Curves

The ability to import complex curves into CNCs promises to let shops finally get beyond old limitations imposed by contouring with linear interpolation. Faster and smoother cutting will be the result.