Five-Axis Machining For The Masses

Control technology continues to make five-axis machining easier to use. Many special considerations - particularly qualified tools for pivoting-spindle machines - are no longer essential to the process.

Share

First, the problem of limited memory was solved. A complex five-axis program is likely to command more CNC memory than a comparable three-axis program, if only because there are two more axes to define. However, back when Min-Max Machine (Ronkonkoma, New York) first started serving its aerospace-industry customers with five-axis machining work, the shop didn't have CNC memory to spare. Instead, Min-Max programmers made themselves experts at writing code efficiently. They learned strategies for defining tool paths using the fewest characters possible. They made a habit of using subroutines, instead of allowing characters to be wasted on repeating identical moves. And while this hands-on familiarity with the code still serves the shop today in many ways, company president Randy Neubauer admits that this expertise is no longer so critical to the shop's use of five-axis machining.

"Today, you can know a lot less and still do good five-axis work," he says.

There are a variety of reasons why. Just one is that the cost of CNC memory has come down. For example, in the control for the five-axis machine the shop bought two years ago, complex programs generated from CAM software—even with little attention to minimizing file size—can almost always be stored with ample memory to spare.

However, this reduced need for strategic programming is part of a larger trend: Disciplines that were once essential to using five-axis machining effectively are now becoming unnecessary, thanks to improvements in CNC technology.

Another example illustrates this trend even more strikingly. On Min-Max's newer five-axis machine—a machine with a pivoting spindle head—qualified tools are no longer required.

This is not the case with the shop's original five-axis machining center. Like many five-axis machines, this one leaves no room for tool dimensions to be determined after the program has been posted, particularly if the program involves interpolated five-axis milling. This machine, too, features a pivoting spindle head. And to allow for the fact that the tilting head leaves tool tip position constantly subject to change, Min-Max must write its programs for this machine with specific tooling gage lengths in mind. Operators then set tools so they conform to these lengths to within ±0.010 inch. This fine-tuning of the tools takes about one-half day per five-axis job, over and above any other setup work the job requires.

The shop's newer five-axis machine does without this exacting work. On this machine, using a program that has already been posted, the shop can run a given cut with tooling that produces a gage length of 10 inches or 15 inches or whatever—it doesn't matter. That's because the CNC for this machine allows tool dimensions to be entered by the operator as offsets, just before the program is run. The result is a five-axis machining center that—in this respect, at least—behaves like any comparable three-axis machine.

Min-Max is not a large shop. It has 18 employees. Out of nine CNC machining centers, only these two perform full five-axis work. However, the differences between the two five-axis machines—one purchased 10 years ago, the other more recently—illustrate how much more accessible five-axis technology has become. Five-axis work once demanded five-axis expertise, but today that is less often the case.

And the most important reason why is that today the control can do more.

Setting Tools Free

Min-Max's newer five-axis machine is a Nicolas Correa bridge-type with a gimbal head and a Siemens (Elk Grove Village, Illinois) Sinumerik 840D control. The machine has larger travels than the shop's first five-axis machine. It offers 100 inches in X versus 60 inches on the older machine. Rotary axes are also more generous. The older machine's fan-saddle design limits each rotary axis to ±25 degrees. But on the newer machine, the gimbal-head design provides rotary-axis travels of +110/-90 degrees in A and ±200 degrees in C. The result is a very different sort of five-axis machine for the shop—a fact that is germane to this story because it affected the shop's acceptance of the machine's CNC.

There was a time, says Mr. Neubauer, when the prospect of bringing in one CNC different from all of the others in his shop would have stopped him cold. However, he is changing that view, in part because today's more computer-friendly operator seems more flexible at adapting from one control interface to another. But in addition to that, this machine was already different enough that any control differences would not significantly add to the learning curve.

The most important similarity between Min-Max's two five-axis machines is that both achieve rotary-axis motion by pivoting the spindle head, not by pivoting the workpiece. Historically, this configuration has had the shop spending valuable time on qualifying tools.

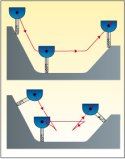

Any shop experienced with such a machine knows why. On other types of machining centers—including any typical three-axis machine—the position of the tool tip moves in lock-step with the linear axes. It's not even necessary to think about tool tip motion or axis motion independently. For these machine types, allowing for the tool dimensions is simply a matter of entering tool offsets at the control, just before the tool enters the cut. This is second nature.

However, a pivoting spindle lets the tool tip follow a different path from the movement of the linear axes. And just because of trigonometry, the difference between the two tracks of motion will vary with the dimensions of the tool. So that is why, on a typical pivoting-head machine, the programmer cannot define the axis moves that deliver the correct tool tip motion without first knowing the dimensions of the tool.

Shops handle this quirky requirement of five-axis machining in a variety of ways. One approach is to measure tools first, enter the tool dimensions into the CAD/CAM software, then post out a program based on these specific tools. The drawback to this approach is that an entirely new program has to be posted every time a tool is changed or substituted.

Min-Max favors a different approach. At this shop, programs are written with specific gage lengths (distances from pivot point to tool tip) in mind, then posted only once. Therefore, tool paths for a given job never have to be rewritten. However, the simplicity has a price. Operators must manually set all of the cutting tool and toolholder combinations so they conform to gage lengths the program specifies.

But the newer five-axis machine makes all of this work unnecessary. On this machine, the control compensates for tool dimensions automatically. This compensation is fundamental to any three-axis machining center, but even in five-axis machining, the idea is nothing new. Controls have long been available that can adjust tool offsets for rotary-axis moves outside the cut—that is, for rotary moves to position the tool for an otherwise linear pass. However, the control Min-Max uses goes further by updating offsets in real time. The functionality makes it possible to use traditional tool offsets even in full, coordinated five-axis milling—and thus avoid the need for qualified tools.

On Min-Max's newer five-axis machine, a broken tool doesn't demand that the replacement tool be carefully set to the right length in the toolholder. Nor does it demand that the program be posted again. Instead, the remedy for a broken tool is the same as for a three-axis machine: Just load a new tool, enter new tool dimensions at the CNC, and resume cutting with the new tool in place.

One Program

Control supplier Siemens calls this technology Traori—for "Transformation Orientation." The feature lets the control use a program that has been posted entirely from the point of view of the tool. The posted program doesn't have to give any consideration to the dimensions of the tool. Nor does it give any consideration to the types or addresses of the rotary axes. Instead, the feature lets the control account for all of these variables itself, as it initiates its own coordinated five-axis machining moves in real time.

Functionality like Traori makes the posted program not just tool-independent, but machine-independent as well. Norman Bleier, engineering manager for Siemens, points out how this has implications beyond just reducing tool setting time. Because the control now factors in the addresses of the rotary axes, and because the control accounts even for information as basic as whether the axes pivot the spindle, the workpiece, or both, all of this detail now becomes irrelevant to the program itself. Posted programs can therefore become interchangeable across many different five-axis machines—so long as their controls all have access to this hardware-independent programming.

To the shop with a bank of identical five-axis machines, this interchangeability may not offer much. But to the five-axis shop with a variety of machine models and rotary-axis configurations, interchangeable programming can make for a far more flexible process. Even in the latter shop, any five-axis part needs only one NC program, now and for all time, no matter what machine might be assigned to run it.

"A vision familiar in the aerospace industry is the idea of `design anywhere, machine anywhere,'" says Mr. Bleier. "With Traori, we're much closer to the `machine anywhere' half of that goal."

The New Process

For now, Min-Max Machine benefits just from the savings in tool setting time. Though operators have not lost their touch for tool setting any more than programmers have lost their feel for the code, the tool-setting skill is now less critical to five-axis machining.

Once, this shop's five-axis programs often had to be strategically written and edited to ensure they would fit in the control. Then, tool lengths were set to make all the tool paths come out right, because every five-axis program assumed specific tool dimensions.

But now, Min-Max can output a long program, send it straight to the CNC of the shop's newer five-axis machine, and use whatever appropriate tooling is available for any given cut—saving time and reducing the chance for error.

In other words, in this shop, many five-axis jobs today don't require any special process considerations.

That is, they require no considerations over and above what would be required for a comparable job using just three axes instead of five.

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

Four Types Of Five-Axis Machining Centers

Different machines offer different approaches to rotary travel, and each design has its own strengths. Here's how they compare.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)