Share

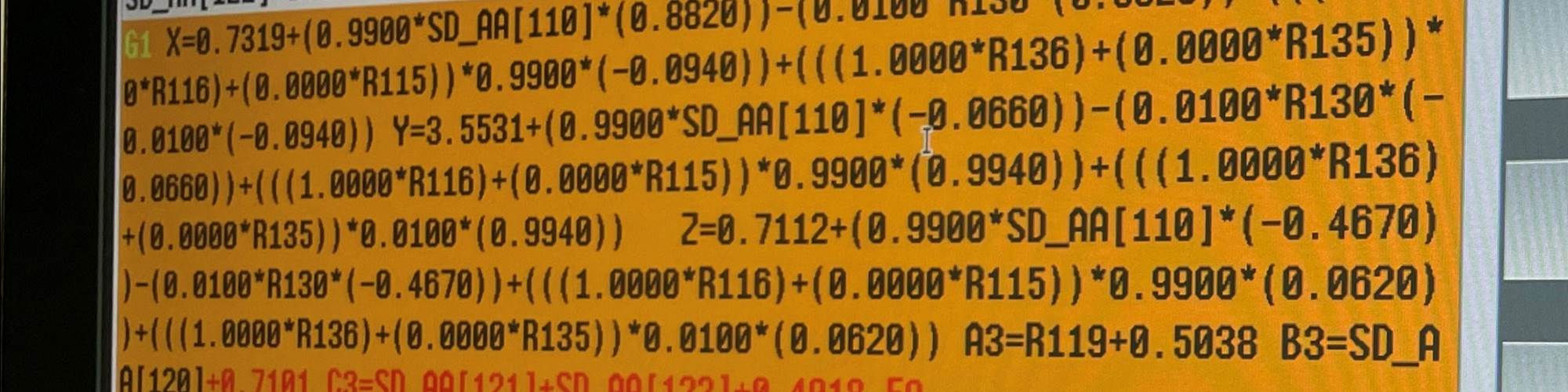

Edwin Gasparraj writes CNC machining programs in which the X, Y and Z axis moves, as well as rotary axis moves, are all algebraic expressions that are full of variables. One line of programmed motion in one of these variable-filled programs could be 700 characters long. Running a variable-dependent five-axis program could have the CNC processing over 10,000 characters per second. Today’s controls can handle it, he says.

Edwin Gasparraj leads SixDigma, a digital manufacturing lab and consultancy. Photo: SixDigma.

Gasparraj leads SixDigma, an Ohio-based digital manufacturing lab and consultancy he founded. The firm helps manufacturers meet vexing challenges in five-axis machining. He says the truth too few realize about modern CNC machining centers is this: They are capable of tighter precision than we ask of them.

The reason that potential goes unrealized has to do with limiting assumptions in the way we program them, he says. At the level of the most minute positioning a modern machine tool can achieve, the machine’s positional consistency is likely tighter than that of the workpiece itself, because the part is in flux in various ways. It moves, it changes and it varies from piece to piece. Identify the inconsistencies and factor them into programming, Gasparraj says, and machining accuracy tightens.

Additive manufacturing is bringing this home, he says. Machining has always dealt with organic parts lacking good locating surfaces for machining, notably castings. But castings are frequently high-volume — there is room for scrap. AM, by contrast, produces a hard-to-locate part that might also have over 100 hours of printing time invested prior to machining. To scrap the part in machining would be too costly to allow.

That is why Gasparraj cringes a bit when he hears machining lumped in as part of “postprocessing” for AM. Sometimes it is that, as in some support structure removal. But when machining is required to realize external features that maintain a precise wall thickness relative to hidden passages printed inside the part, this is a different matter. His firm has repeatedly confronted this very challenge with machining for AM. This is where the technology available for machining is allowing it to keep up with 3D printing, he says, and where additive manufacturing will be revealed to be an undertaking that brings 3D printing and machining together.

At his facility, CNC programs his team develops are proven on two Grob five-axis machining centers using Siemens controls. Programs with variable-dependent XYZ moves and tool-axis vectors are developed to machine challenging castings and forgings, as well as AM parts.

Rather than fixed numerical toolpath moves, programs based on workpiece-dependent variations include variables in each line. Photo: SixDigma.

The AM parts, usually made through powder bed fusion, are near-net-shape, but not near enough. The outer form of the as-printed part follows the CAD model with a tolerance band that is loose relative to machining. Ditto for the inner form, the passages and cavities printed inside. So this is where advanced measurement must assist machining toolpaths: SixDigma uses optical and CT scanning equipment from Zeiss to model outer and inner geometries, respectively. With these outer and inner models as a guide, the variable-dependent toolpaths essentially let the CNC precisely position and orient the coordinate reference for the machining program, so that the program accurately finds the finished part within the envelope in between the as-printed outside and inside surfaces.

And the variation does not end with this starting geometry. In-process probing of external references can track for temperature-induced shifts in the part during machining, Gasparraj says. Then there are the shifts from the tension built into the part due to material formation. On one AM component he showed me, the needed precision was so tight that the part’s position in its heat treat furnace proved to be an important determinant. Variables written into the CNC program account for this position, because this has been shown to influence the way the part shifts during cutting due to internal stress.

What all this means is that the comparison of additive and machining as “new” versus “conventional” manufacturing methods partly misses something. For starters, the reference point in a comparison like this is no more static than workpieces are. New technologies do advance quickly, but established technologies do not stop changing themselves. Secondly, these technologies affect one another. We will learn more about machining because of what AM asks, and the gains will extend beyond AM. In other words, the lines between manufacturing technologies are not fixed. It is all manufacturing, and all of it is in motion.

Related Content

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreComputer Programming-Related Features of Custom Macro

Custom macro is an interpreter-based language, meaning that all CNC G code and custom macro commands are executed as the CNC comes across them.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More