Integrating Robot Programming into the CNC: One Example

This combination of robotics, CNC, workholding and machine tool technologies resulted in a streamlined way to integrate and program an automated machine-tending process.

Share

For this demonstration, the robot performed both workpiece pallet changeout and simulated polishing operations of machined parts.

I’ve been aware of the Run MyRobot capability available with Siemens Sinumerik controls for a little while, but I believe the cell below that was in Handtmann’s EMO Milan booth represents the first time I’ve seen a demonstration of the concept using an actual machine tool.

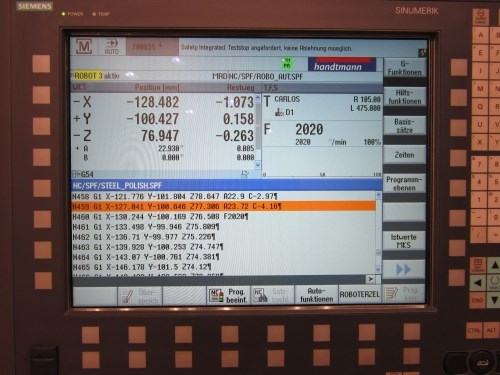

The idea is to provide intuitive robot programming capability at a machine’s CNC via the Sinumerik Operate GUI. In the case of this cell, the execution of the movements of the six-axis Kuka KR 600 Fortec robot (with 600-kg load capacity), provision of robot safety functions and other robot-specific functions are performed by the Kuka KR C4 robot control. However, that control is connected to the Handtmann five-axis HBZ Trunnion 80 machine’s Sinumerik 840D sl CNC. Therefore, the machine tool operations and robot program can be tracked and controlled on one screen via parallel channels.

The machine tool operations and robot program can be tracked and controlled on one CNC screen via parallel channels (the robot channel is shown here).

For this demonstration, the robot performed both workpiece pallet changeout (using Schunk clamping systems) and simulated polishing operations of machined parts. Of course, the robot can be used to perform a range of secondary operations, including drilling, brushing and deburring, depending on a manufacturer’s needs.

Check out this video that shows the cell at the show.

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.