Seeing More For CNC Multi-Spindles

Motor technology, machine design and software possibilities all improve the economies of these sophisticated high-volume machines.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreFor shops that are accustomed to cam-driven multi-spindle turning machines, CNC multi-spindle turning machines are not necessarily the next step. Thanks to all of the axes under control, the CNC multi-spindle is considerably more expensive. As a result, such a machine generally gets applied to particularly high volume jobs involving challenging features or exotic alloys that can justify the high cost.

But what about other high-volume jobs?

The multi-spindle concept, with its ability to machine many features simultaneously, remains effective for machining large quantities quickly. That’s why cam-driven multi-spindles have continued to remain competitive, and the principle applies to CNC machines as well. Can shops that are transitioning beyond their cam-driven multi-spindles consider a CNC multi-spindle for high-volume parts that are simpler, and parts that are made of steel?

Perhaps they can. The prices of motors and other CNC components are coming down. The machines can be designed to leverage the motor-technology improvements to realize further savings still. An example of such a machine will be available from Index Corporation (Noblesville, Indiana) in July. With its new MS22C six-spindle machine, the company aims to expand the market for CNC multi-spindles from their high-value niche to include medium-value work as well.

The design of this machine allows it to achieve a 25-percent price savings compared to previous six-spindle machines with the same workpiece capacity. A study of this machine reveals the impact of motor improvements, as well as the modest design considerations that are sufficient to complete the price reduction. In addition, software that the same company developed jointly with Siemens further enhances the cost efficiency compared with multi-spindles of the past.

Simultaneous Machining

For the uninitiated, a multi-spindle turning machine has different tool carriers at every spindle. A six-spindle machine can therefore perform six different operations at the different stations. On the Index machine, each tool carrier can perform OD or ID work, or live-tool milling or drilling, depending on the tooling and accessories at each carrier. As the spindles move from station to station via an indexing drum, the workpiece receives each of the different machining operations in turn. With the different spindles each carrying a different workpiece, all of the machining happens at once. Each one-sixth turn of the drum delivers a new part to the pickup unit, making cycle times tiny indeed. Truly, these are high-volume machines.

The amount of all of this simultaneous motion suggests why the machine might be expensive. To understand the cost reduction mentioned above, it’s important to appreciate just how many axes there are. To the CNC, every controlled element is an “axis,” including not just the motions in X and Z at all of the various tool carriers, but also the speed-controlled spindles, the motion of the

pickup unit, the additional back-work spindle on the pickup unit itself and even the motion of the indexing drum. All of these components have servomotors, and Index president and CEO Olaf Tessarzyk says the evolving technology of motors has made them more economical in at least two ways.

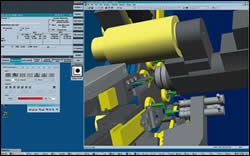

One is the straight purchase price. A new generation of stepless-drive motors is cheaper, he says. At the same time, these motors have steeper power curves, meaning they accelerate more quickly from zero to full speed and back again. This lets the machine use smaller motors to do the same work, which represents the second source of savings. Smaller motors simplify machine design, because the compact motors can mount right on the ends of the axes in a direct-drive configuration (see photo).

Yet the motors represent just part of the control system. Another component is the electronics, including the control unit within the CNC. The control unit for a machine like this can accommodate as many as 31 axes. More axes require dual control units within the same box. To achieve an economy multi-spindle, the designers of this machine therefore held the number of axes to 31, shaving away motion here and there. The MS22C thus has two axes of motion not on all of the tool carriers (like other MS models), but instead only on most of the tool carriers. Of the 12 carriers (two for each spindle), three are limited to X-axis motion and two are limited to Z-axis motion.

The Z-axis carriers are drill slides. They move parallel to the spindle to carry tools into the face of the part. The X-axis carriers are plunge slides, moving radially into the OD of the part. The user is likely to equip these with form tools. The seven remaining carriers permit interpolated motion in both axes together.

In short, while there are still plenty of options for multi-axis tool motion throughout the stations of the machine, the range of those options is somewhat reduced. But again, this machine contemplates potentially simpler parts. (And the user can always upgrade the machine later to add the axes that are missing.)

Simulated Machining

These design and hardware changes affect the price of the machine. However, that price is not the only cost that has to be amortized across a high-volume job. Another is the cost of setup, and Mr. Tessarzyk says claims of setup time tend to understate just how much setup-related work is required.

Specifically, setup goes beyond loading material and changing tooling to include the time required to prove out a part program. On a multi-spindle, the synchronized machine motion is complex enough that a number of sample parts may be needed before the program can be fine-tuned to both the productivity and the dimensional performance that are possible. New software—“Virtual Machine” from Index and Siemens—can speed this process by allowing the prove-out to be performed away from the machine.

Siemens participated in the development of this simulation software because the software does more than just portray the machine’s movements. Instead, the software executes the NC program through the 840D control. Elements of the virtual multi-spindle machine in the software then model the inertia and performance of the actual elements of the user’s machine. As a result, the software’s response closely matches the multi-spindle machine’s response. A program run through this software is run on a machine—just a machine that is made of CAD models instead of hardware.

The part produced by the software cycle is a precise 3D model as well. The user can import this part model into a third-party CAD system to inspect whether the program has machined the part to spec.

The point of this software is to save setup time and expense, but in addition, Mr. Tessarzyk says it takes away a bit of the “fear factor” of using a CNC multi-spindle machine. Versions of the software are available for all of the company’s machines, but this advantage related to user confidence may be particularly relevant to the MS22C. A user who does purchase this machine for medium-value work might never have used a CNC multi-spindle before, and such a user might indeed be initially over-cautious with the machine. Proving out the parts off-line can let this user grow in confidence more quickly—perhaps even growing to the point of taking on higher-value jobs as well.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreIndustry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)