Control Package Helps Speed Production

After cutting precision parts in one third of the original time, Task Force Tips was able to justify its initial investment in an Index automatic production lathe fitted with a Siemens control package.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Learn how the Index C100 and Siemens 840D control package improved setup times without sacrificing cycle time, enabling Task Force Tips to cut production time by one third.

Even though Task Force Tips (TFT) knew implementing higher-priced, high speed machining options would improve its production capabilities, it resisted making such an investment. “I hadn’t really looked at the economics when it came to an Index machine,” says company owner and President Stewart McMillan. “I never even thought the company’s machines were within our league,” he says. However, he soon realized his error in judgment after purchasing an Index machine and ultimately powering it with a Siemens control package. With this combination, TFT’s production times dropped to 30 percent of what they once were. Mr. McMillan says this was a wake-up call.

TFT is a manufacturer of highly engineered fire suppression tips, nozzles and other agent delivery equipment used by fire departments globally. It manufactures more than 5,000 products across three shifts, seven days a week in its 168,000-square-foot facility in Valparaiso, Indiana. At the International Manufacturing Technology Show (IMTS) 2008, the company decided to purchase a C100 automatic production lathe from Index Corp. (Noblesville, Indiana). Soon after, TFT realized it was pushing the new machine beyond the capabilities of the CNC that powered it. When Index learned that the new machine was underperforming, the machine tool builder swapped it for a model with an 840D control package from Siemens Industry Inc. (Elk Grove Village, Illinois).

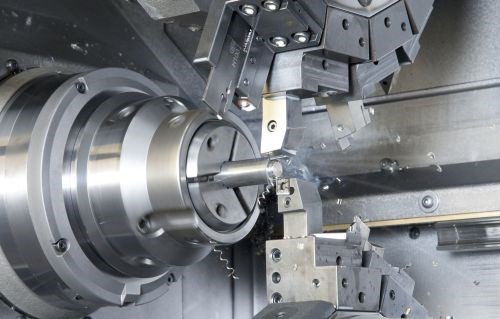

Before long, the new machine was cutting parts in one third of the time it previously did. TFT began running jobs at 5,000 to 6,000 RPM, ramping up from 0 to 5,000 RPM in less than 1 second, and ramping down just as fast. “We never realized before just how much time we were losing waiting on the spindle to stabilize at a new command speed,” Mr. McMillan says. Turret indexing is also fast, he says. Multiple tools overlap to cut at the same time with fast accelerations.

The Index C100 also leverages speed in new ways. For instance, the company can run more than 1,000 parts without having to change an offset. In addition, an automated remnant removal feature enables the machine to run continuously by rapidly reloading barstock without operator attention. On the rest of the company’s machines, operators must pick the remnant out and load new bar. While that step should only take a few minutes, Mr. McMillian says that oftentimes a machine can sit idle for close to 6 minutes before an operator reloads the machine—a process that takes 5 minutes. This lost time adds up, he says.

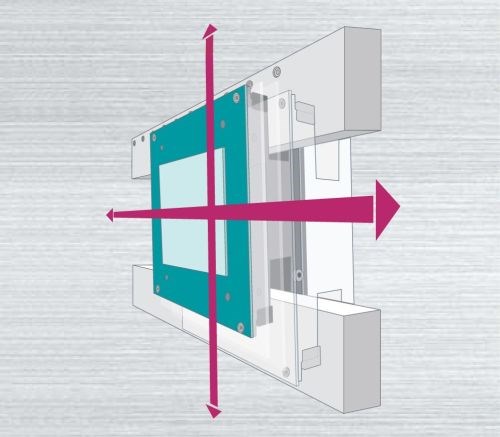

Another speed-related improvement was the machine’s fast rapid traverse rates, which have always been less than rapid in the company’s experience. “A lot of machines advertise rapid traverse rates at maximum speed, but the fact is, unless you’re traveling 10 or 12 inches, traverse speeds have never reached maximum for us,” Mr. McMillan says. He attributes this to structural design features. For example, the machine uses a set of parallelogram bars instead of a conventional coordinate system. “The machine has a picture frame mount for its turret. The turret is not leveraged off a set of ways like most turrets. It’s close to where it’s sliding, so there’s not a big length over diameter ratio in terms of the tools of the turret hanging out from its support structure. This gives the machine a lot of rigidity for turning, and you can accelerate the axes so fast that you really do achieve faster traverse rates,” Mr. McMillan says.

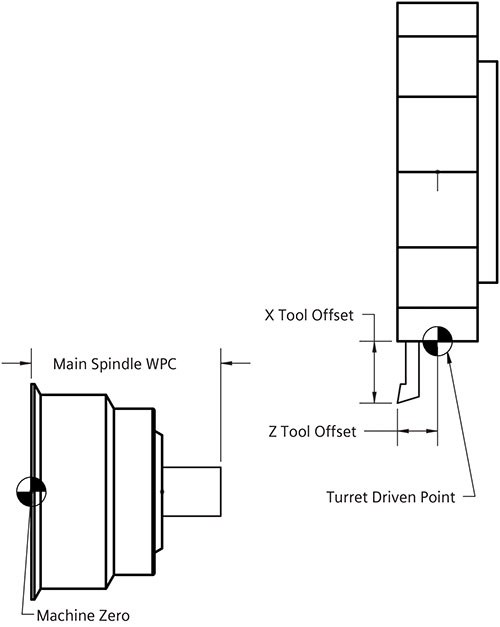

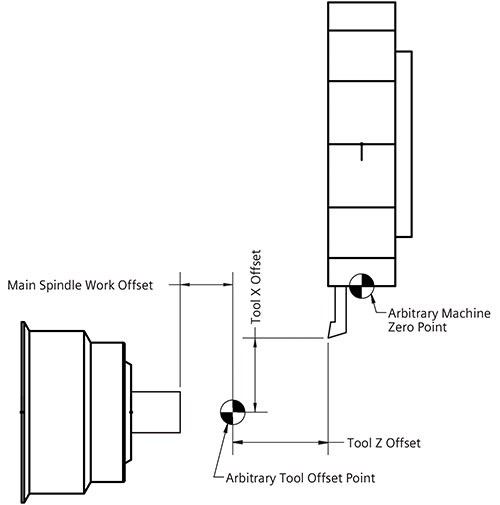

According to lead programmer Nate Price, the Index C100’s parallelogram coordinate system offers additional efficiency advantages because measurements and motion can be programmed based on actual numerical reference points instead of arbitrary points in space. “On the Index, every machine space coordinate, every offset, every measurement that’s used to define how the machine operates has a legitimate explanation of why it is what it is and to where it relates,” Mr. Price says. “This makes it much easier to automate these measurements. In the past, we would measure manually because there were arbitrary points. On the Index, they are defined, literal points,” he says.

With the Siemens 840D driving the Index machine, TFT experienced reduced setup times. The faster indexing speed of the turrets contributed to an 80-percent reduction in setup times compared to those of TFT’s other machines.

In addition to easier programming and faster setups, Mr. Price says the Siemens control enables machinists to more efficiently control and capitalize on the machine’s production potential. For example, the control enables them to take ample shortcuts. “There is a method of presenting messages to the operator that was not present in the other control,” he says. “There is so much happening on the machine, it is difficult to capture all that information on a single screen, but the control helps you keep track of what everything is doing. It’s really easy to get into more detail without having to go through a lot of pages,” he says.

As another example of the CNC operational efficiency, Mr. Price points to the way the control manages error messages. “The machine wants to see several conditions exist before it will start a cycle,” he says. For instance, the chucks should be closed and the gantry and subspindle should be in a safe position. If those conditions aren’t met, the control guides operators through the changes required to start the cycle.

Tool loading was another big area of improvement, Mr. Price says. Essentially, the programmer tells the control which tools will be used for the job by entering a mini-program, he says. During setup, the control presents the stations on the turret and tells the operator which tools need to be put in and taken out. “This guided process has been a huge departure from what we traditionally have dealt with. It really accelerates setup time,” Mr. Price says.

The new machine tool and CNC have helped Mr. McMillian look at the numbers from a different perspective. For instance, there are initial and ongoing costs to build a shop, from putting in a roof and floor to heating and cooling. All these costs equate to so much per hour, he says. When considering investing in a new machine, he began looking at the difference between purchasing a $600,000 machine versus a $300,000 machine over 10 years and realized the difference was only $8 per hour. “For $8 more an hour, we’re getting triple the production out of the same square footage,” he says.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)