Die/Mold

Complementary Technologies Make MQL More Accessible

An add-on system for minimum quantity lubrication (MQL) combines an external pump with repeatable control over nozzle position.

Read MoreMilling Cutter For Increased Chip Evacuation

The Z-Plunge milling cutter from Kennametal is suited for aerospace, die and mold and general engineering applications. The cutter is designed to increase chip evacuation and productivity. Four cutting edges per insert offer good economy, the company says.

Read MoreGetting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

Read MoreHigh-Speed VTCs

GBI Cincinnati’s SMS CNC, high speed vertical turning centers are said to be ideal for mixed volume, short-run operations as well as dedicated high-volume applications. With a swing of 650 mm and a maximum turning diameter and height of 610 mm and 505 mm, the SMS AC-600 combines high-performance turning and large machining capacity within a compact 1,700- × 1,600- × 12,942-mm footprint. X-axis travel is 306 mm and Z-axis travel is 505 mm.

Read MoreKeeping Things In Focus

Machine-mounted video cameras are part of a system that help a shop owner get more work done while spending less time in the shop. He can monitor and control what’s happening on his machines remotely. He’s also developed strategies for reacting to events such as unexpected tool wear or sudden tool breakage without returning to the shop to fix the problem.

Read MoreAlternate Tool Material For Hogging Large Workpieces

Shops often use either carbide or high speed steel cutting tools for hogging out the large workpieces common to the aerospace and moldmaking industries. While both materials have their advantages and disadvantages, cutting tool manufacturer Precision Cutting Tools says powder metal combines the best features of both.

Read MoreCAM System Simplifies Tire Mold Programming

PROBLEM: Segmented tire molds required complex, time-consuming programming SOLUTION: HyperMill CAD software from Open Mind RESULTS: Improved delivery time, part quality Chris Sipe, owner of Northeast Tire Molds in Akron, Ohio, likens machining tire molds to evolutionary theory—while some firms go out on a

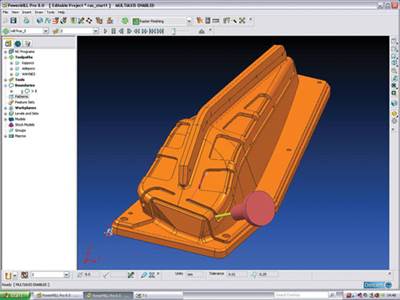

Read MoreMold Maker Cuts Delivery Times With CAD/CAM

Staying competitive in the automotive industry requires quick turnaround, a fact not lost on this manufacturer of foundry tooling. Upgrading to a CAD/CAM system from Delcam helped the shop significantly increase machining efficiency and reduce delivery times.

Read MoreThe Case For Constant Velocity

Constant Velocity Technology uses high speed computer hardware and creative algorithms to enable machine tools to achieve fast, consistent feed rates across complicated 3D surfaces.

Read MoreMolding Personnel

This mold shop has a full-time employee devoted to nothing but training.

Read More

.jpg;maxWidth=300;quality=90)